Machining tool detection method

A technology for machining tools and detection methods, applied in the field of detecting whether the machining tools are formed correctly, can solve the problems of damage to the machining tools, inability to cut the machining tools, inaccurate machining, and inaccurate inspection work, and achieve the effect of a small error range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to achieve the above-mentioned purpose and effect, the technical means adopted by the present invention and its implementation mode, the features and functions of the preferred embodiments of the present invention will be described in detail as follows in order to facilitate a complete understanding.

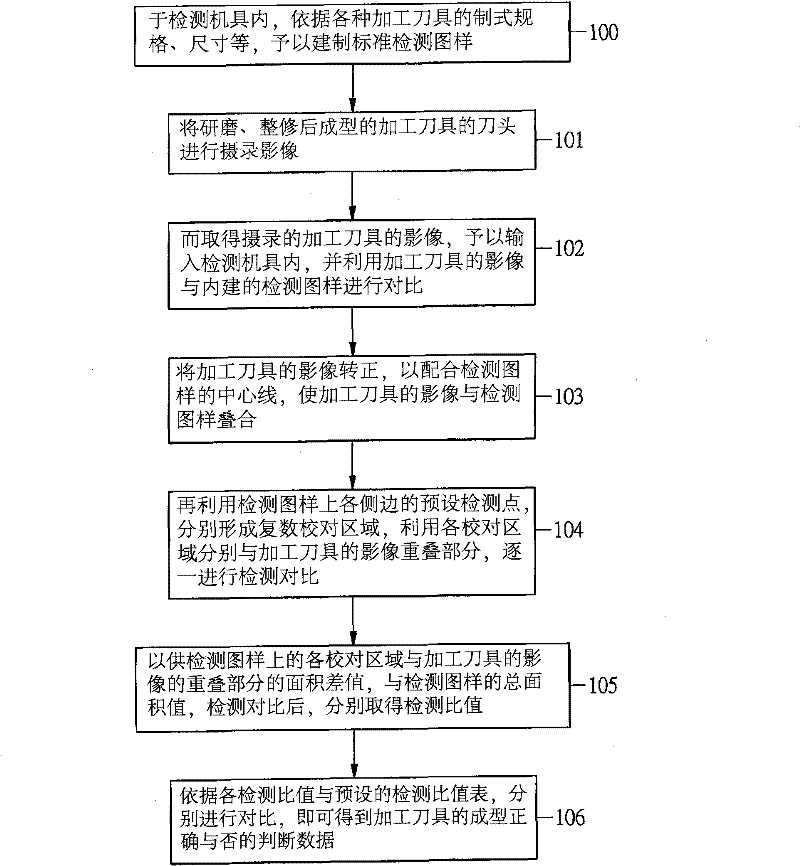

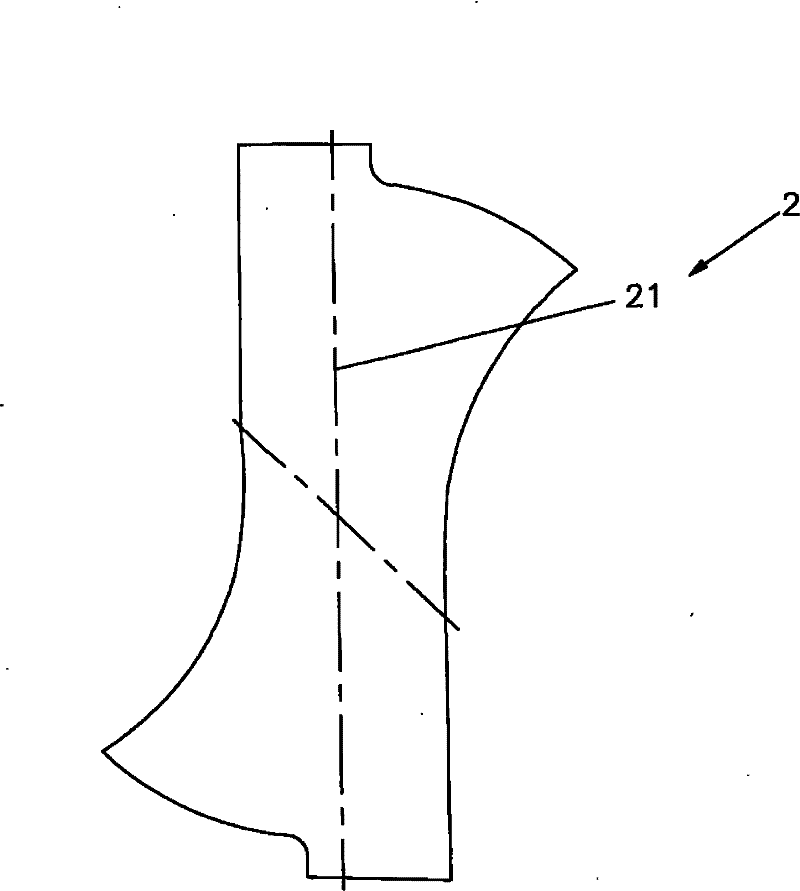

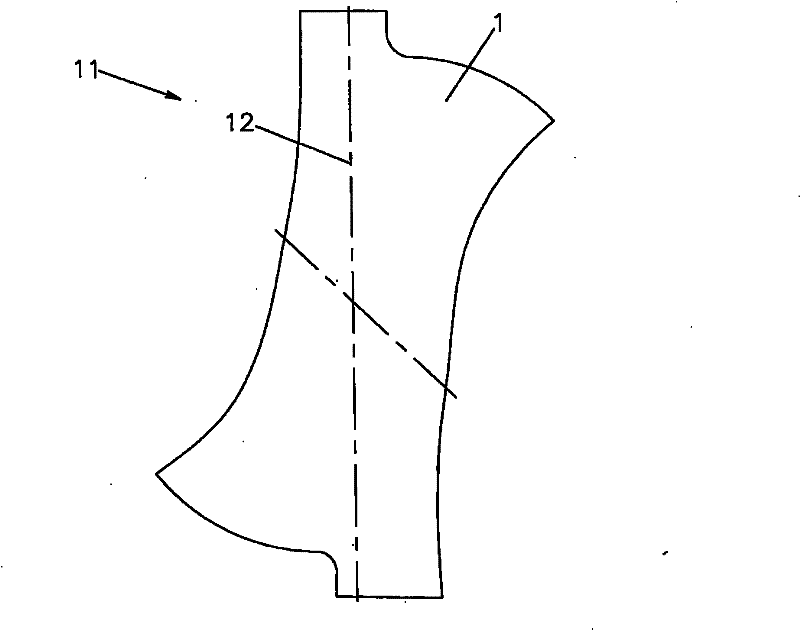

[0042] see figure 1 , figure 2 , image 3 Shown, is the flow chart of the present invention, the plan view of standard detection pattern, processing tool camera image picture and the detection system figure (1) of the actual application of the present invention, the detection system figure (2) of actual application, the detection of actual application System diagram (three), can clearly find out by shown in the figure, the machining tool detection method of the present invention, its detection step is:

[0043] (100) In the testing machine tool, according to the standard specification, size, etc. of various processing tools 1, a standard testing pattern 2 is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap