Hydraulic weighing unit and ten-thousand-ton grade hydraulic electronic scale

A weighing unit and hydraulic technology, which is applied in the direction of weighing equipment, weighing and measuring devices using fluid balance, can solve the problem of limited weight in weighing, and achieve the effect of convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

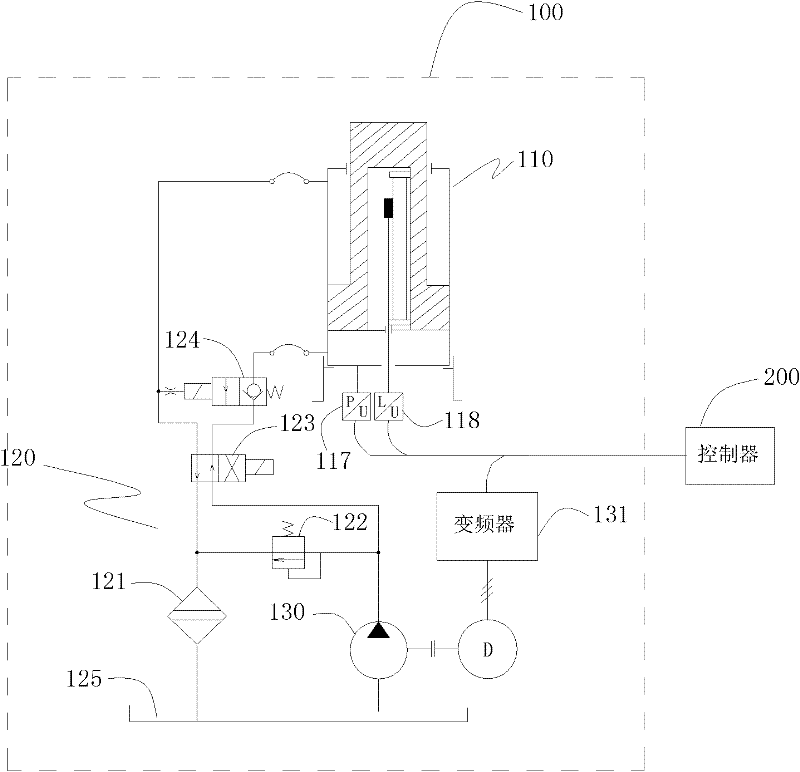

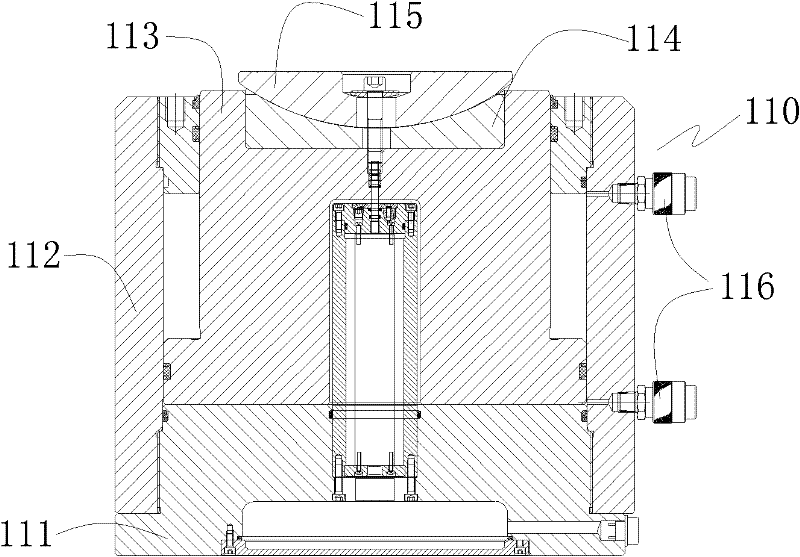

[0024] like figure 1 and figure 2 As shown, a hydraulic weighing unit 100 includes a hydraulic cylinder 110 , a control oil circuit 120 and an oil pump 130 . The oil pump 130 drives the liquid in the hydraulic system to flow in the control oil circuit 120 and drives the hydraulic cylinder 110 to move. A pressure sensor 117 is also provided on the hydraulic cylinder 110 for detecting the current force on the hydraulic cylinder 110 .

[0025] In order to finely and accurately adjust the force of the hydraulic cylinder 110, the hydraulic weighing unit 100 further includes a frequency converter 131 for controlling the motor of the motor-driven oil pump 130. By controlling the motor, the power of the oil pump 130 can be easily adjusted pressure. The frequency converter 131 can also receive the feedback from the pressure sensor 117, and form a force closed loop with the pressure sensor 117 to precisely adjust the force of the hydraulic cylinder.

[0026] As a preferred embodimen...

Embodiment 2

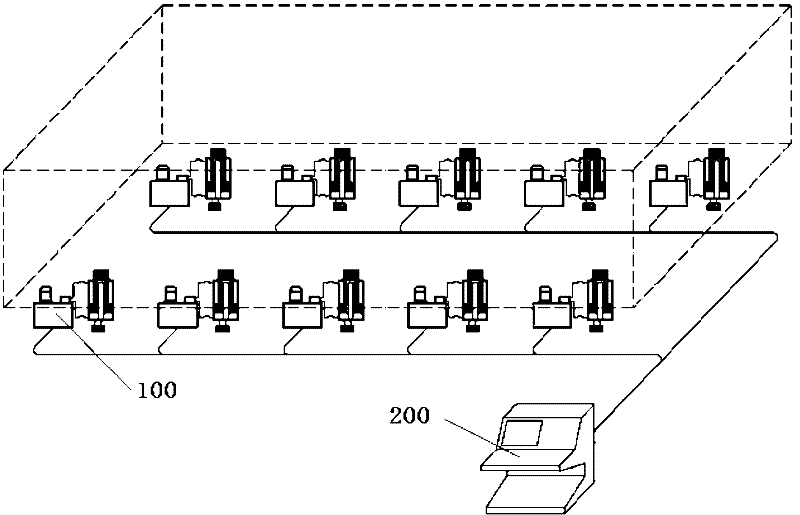

[0030] like image 3 As shown, a 10,000-ton hydraulic electronic scale includes a displacement module and a force module, the displacement module includes at least three hydraulic weighing units 100 described above, and the hydraulic weighing unit 100 is provided with a displacement sensor 118 and a frequency converter 131; The force receiving module includes at least one hydraulic weighing unit 100 described above.

[0031] The hydraulic weighing unit 100 of the force-bearing module further includes a frequency converter 131. In order to finely and accurately adjust the force of the hydraulic cylinder 110, the hydraulic weighing unit 100 further includes a frequency converter 131 for controlling the motor-driven oil pump 130. By controlling the motor, the pressure of the oil pump 130 can be easily adjusted. The frequency converter 131 can also receive the feedback of the pressure sensor 117, and form a force closed loop with the pressure sensor 117, so as to precisely adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com