Microcomputer controlled electro-hydraulic servo large multifunctional pressure shearing tester

A technology of electro-hydraulic servo and microcomputer control, which is applied in the direction of adopting mechanical devices, measuring devices, instruments, etc., can solve the problems that cannot be applied large, cannot meet the diversification and large-scale of roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

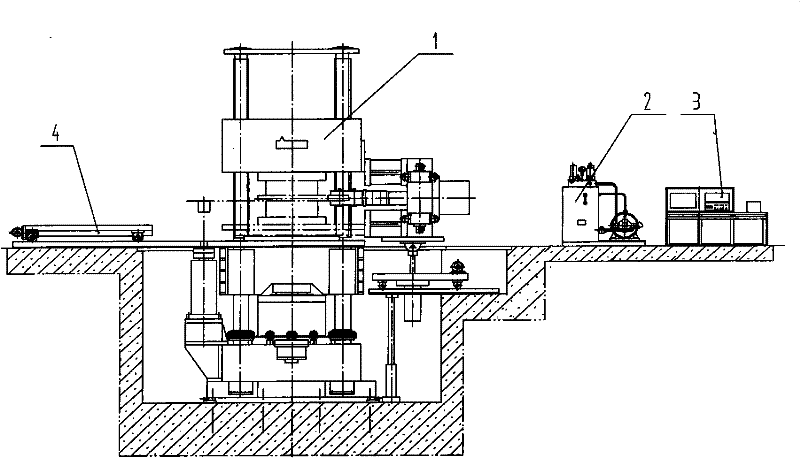

[0013] Such as figure 1 As shown, the present invention is composed of a host machine 1, a hydraulic system 2, an electro-hydraulic servo control system 3 and a sample transport trolley 4.

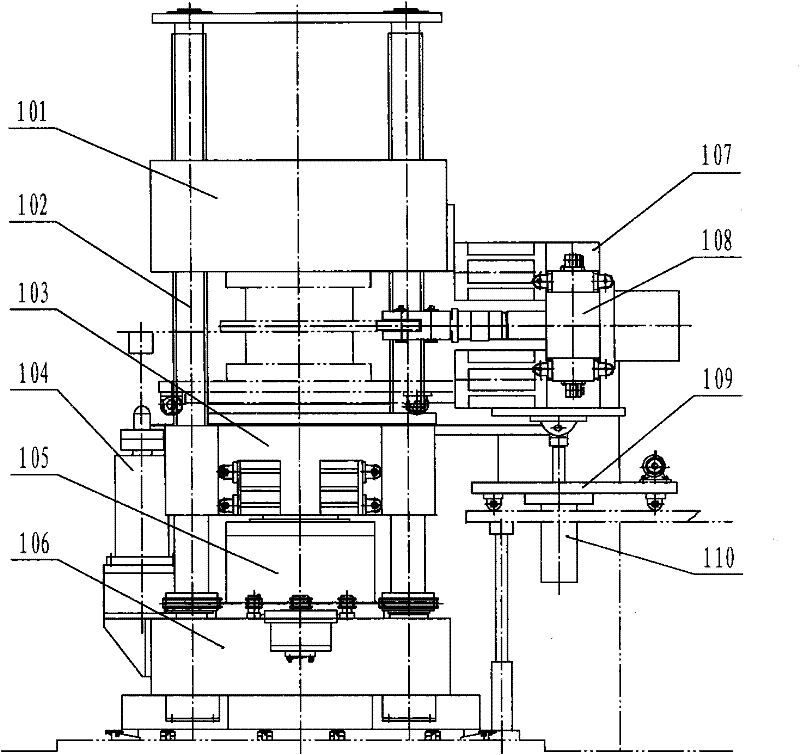

[0014] Such as figure 2 As shown, the main engine 1 includes: a movable beam 101, four lead screws 102, a frame composed of a base 106, a vertical servo loading cylinder 105 installed on the base 106 at the bottom of the frame, a corner servo loading cylinder 104, and the above described Vertically to the box-shaped pressing plate 103 connected by the load sensor to the piston of the servo loading cylinder 105, and the horizontal shearing servo loading device 108 installed on the right side of the frame; the horizontal shearing servo loading device 108 is installed on the mobile trolley 109. The moving trolley 109 is equipped with a guide device 107 for the lifting of the horizontal shearing servo loading device 108, and a synchronous floating servo cylinder 110 is installed at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com