Abnormal abrasion monitoring system and method for boat motive power system

A power system and monitoring system technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of complex sampling process, long sampling period of off-line oil monitoring technology, and insufficient representation of oil samples, so as to avoid long sampling period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

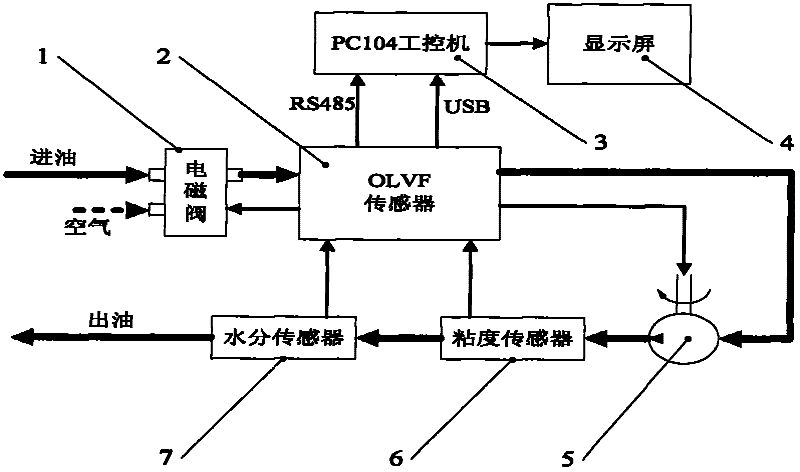

[0041] Such as figure 1 As shown, the present invention provides an online comprehensive monitoring system for abnormal wear oil of a ship power system based on online image visual ferrography, including a solenoid valve 1, an OLVF sensor 2, a PC / 104 industrial computer 3, a display screen 4, and a gear A pump 5, a viscosity sensor 6, and a moisture sensor 7 constitute. The oil in the oil return pipe of the engine is under the action of the gear pump 5, and the oil flows through the solenoid valve 1 through the OLVF sensor 2 to deposit the abrasive particles in the oil. When the abrasive particles are deposited, the solenoid valve 1 shuts off the oil circuit. Connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com