Soaping-resistance color fastness evaluation method of circular screen printed textiles on basis of image analysis

A technology of rotary screen printing and textiles, which is applied in the field of evaluation of color fastness to soaping of rotary screen printing textiles based on image analysis, and can solve the problem of impracticable global measurement of textiles and objective and accurate evaluation of color fastness to soaping of rotary screen printing , can not reflect the fading of textiles and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

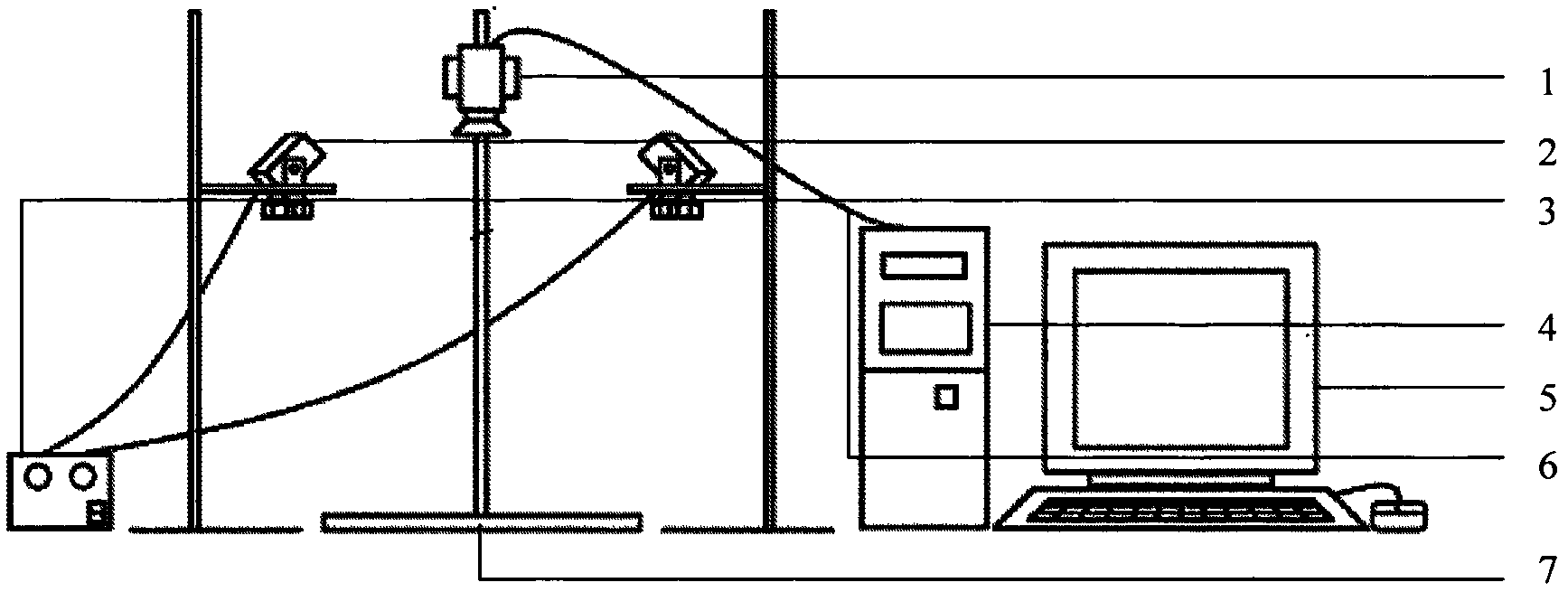

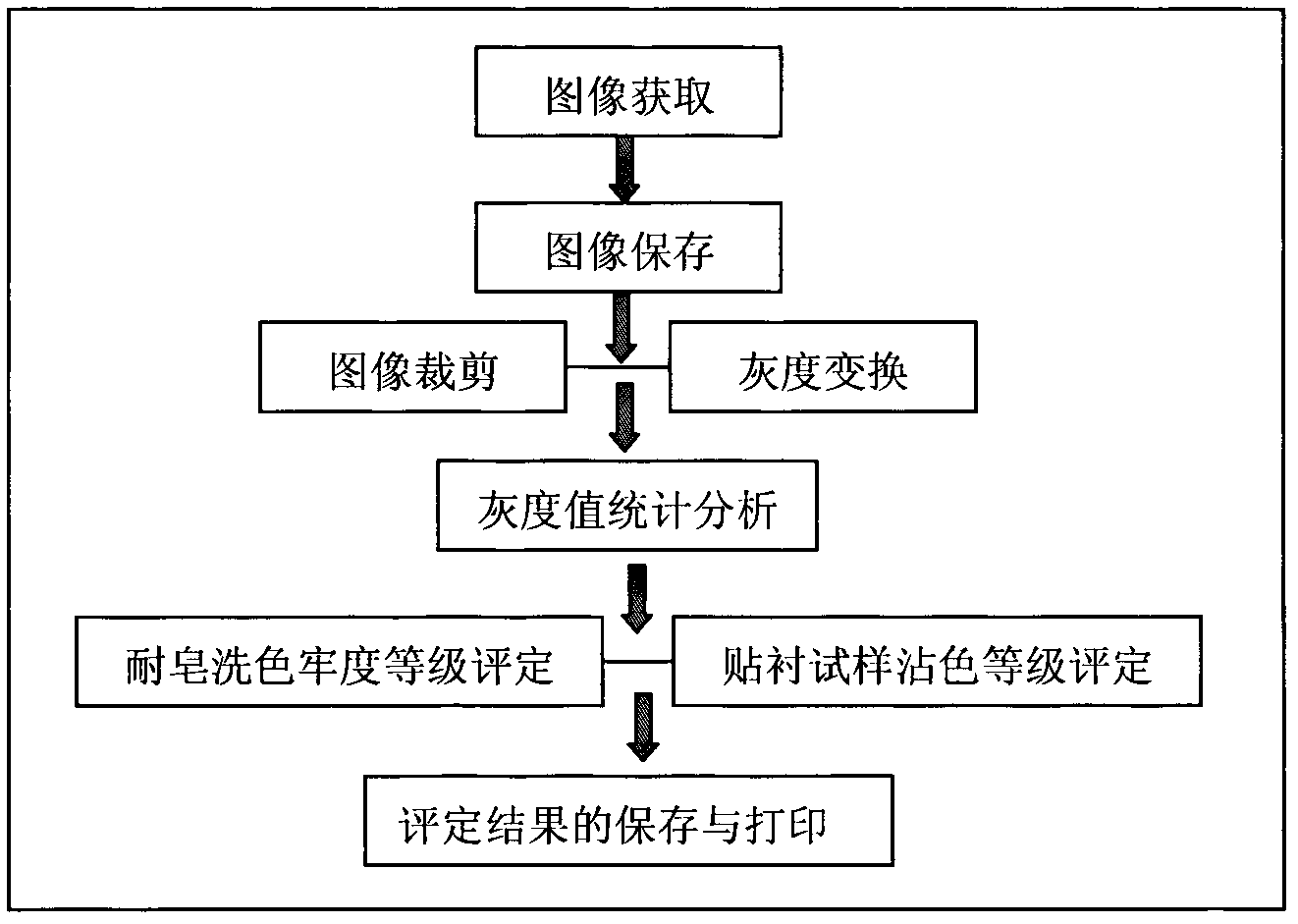

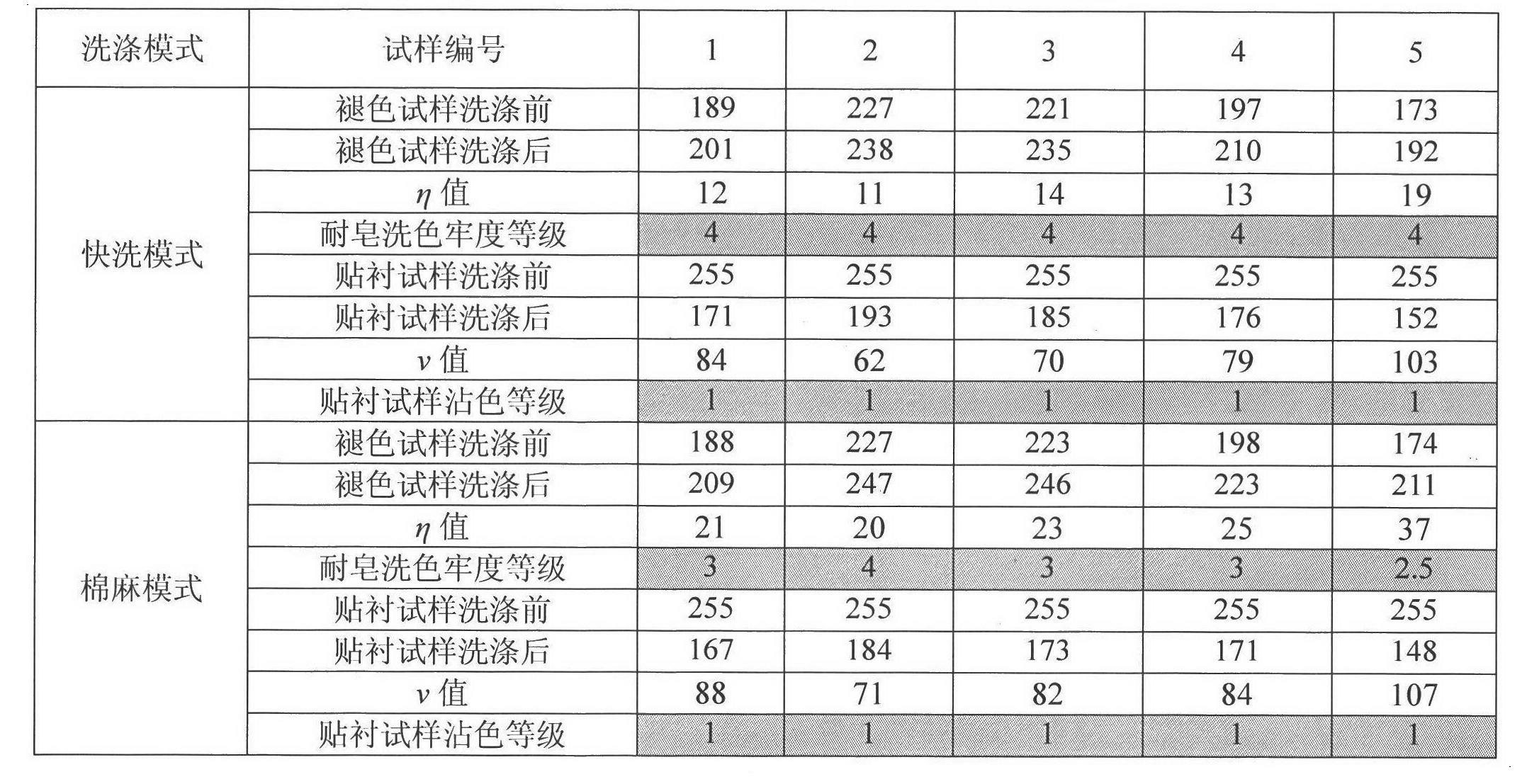

[0013] According to the requirements in GB / T3921-2008, when the sample is a fabric, prepare a combined sample according to the following method: take a piece of rotary screen printing textile sample with a size of 100 mm × 40 mm, and a piece of pure cotton with a size of 100 mm × 40 mm on the front The fiber white backing fabric touches and is seamed along one short edge. In this example, in order to simulate the real laundry fading environment and ensure the stability of the test, five samples were washed at one time with a domestic rolling washing machine. For example, using figure 1 Shown hardware fits figure 2 The shown software takes photos of the rotary screen printing textile samples before and after washing, and calculates the average gray value I of the sample images before and after washing. b and I a . According to the principle of image analysis, it can be seen that the color of the sample fades after washing, the color becomes lighter, and its gray value beco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com