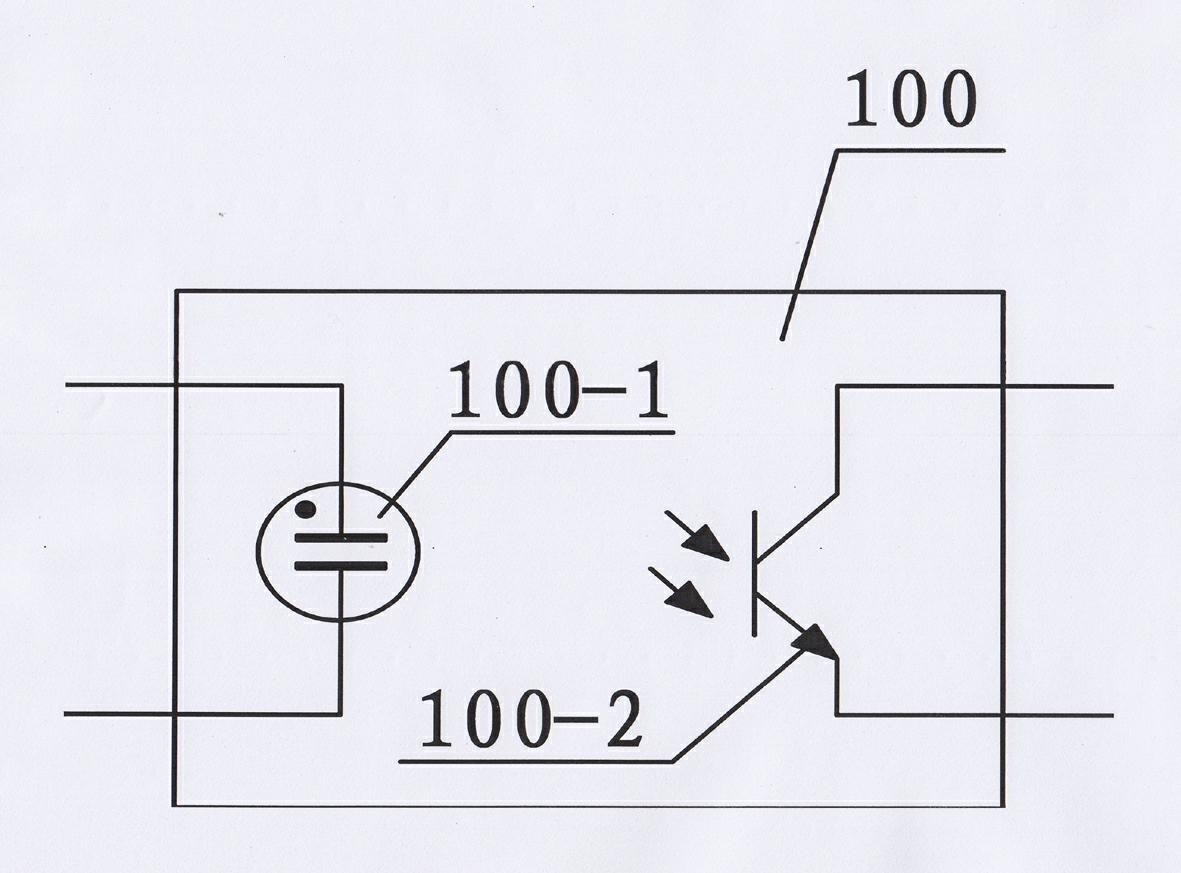

Leakage protection plug

A leakage protection plug and resistor technology, applied in circuits, electrical components, coupling devices, etc., can solve the problems of leakage protection plug tripping, failure to ensure electricity safety, and failure to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

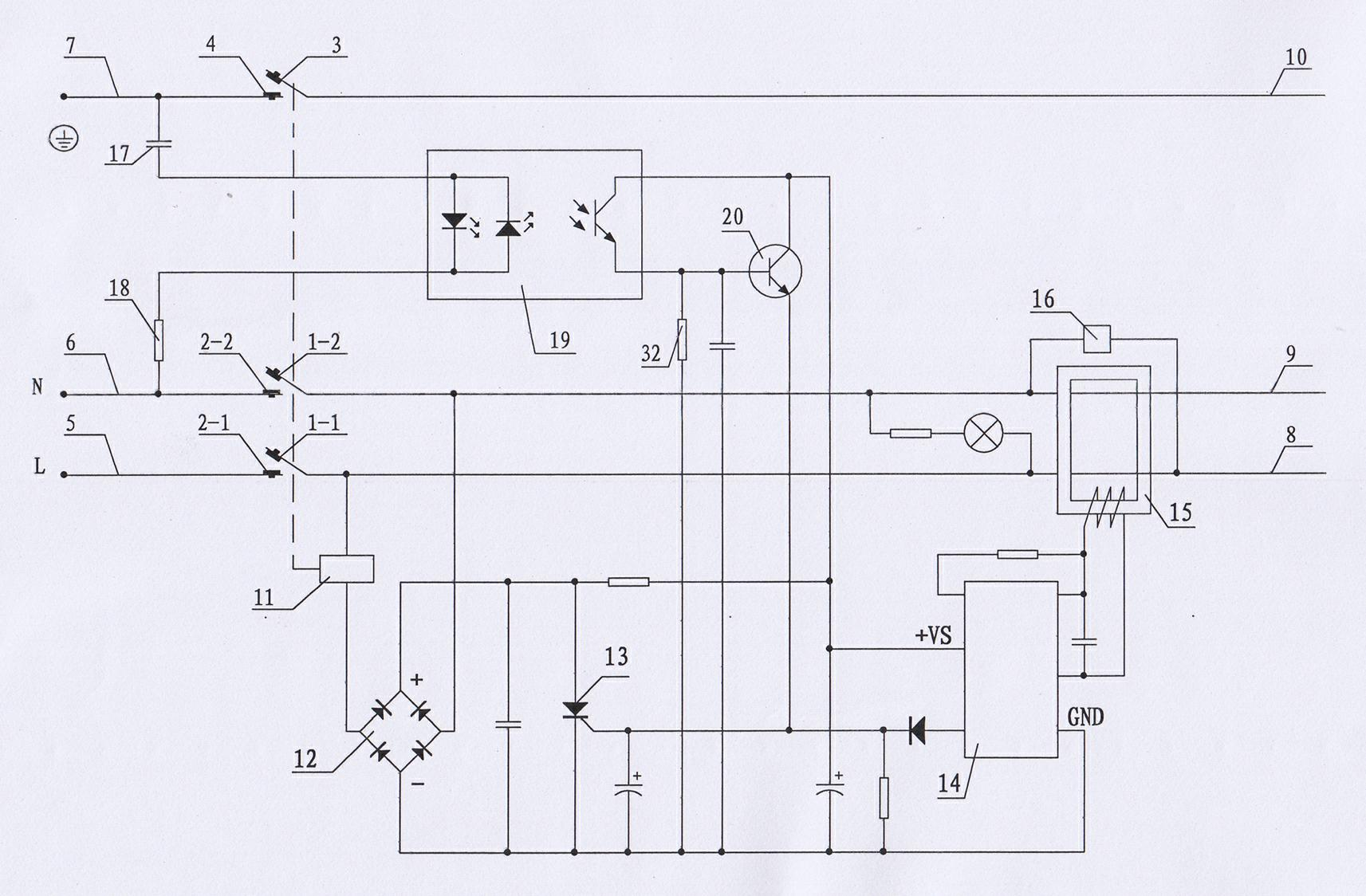

[0046] see figure 2 As shown, a leakage protection plug is mainly composed of a shell and a plug, a phase wire 5 and a neutral wire 6 and a ground wire 7 at the power supply end, a phase wire 8 and a neutral wire 9 and a ground wire 10 at the load end, a zero-sequence current transformer 15, Test circuit 16, electromagnetic tripping and locking device, the electromagnetic tripping and locking device includes electromagnetic coil 11 and its drive circuit, phase line contacts 1-1 and 2-1, neutral line contacts 1-2 and 2 -2. Ground wire contacts 3 and 4, a spring, a reset push rod, a first resistance-capacitance element 17, a second resistance-capacity element 18, a photocoupler 19, and a trigger circuit. Between the ground wire 7 and the neutral wire 6, a detection circuit formed by connecting one input end of the first resistance-capacitance element 17, one input end of the photocoupler 19 and the other input end, and the second resistance-capacity element 18 in series, the ph...

Embodiment 2

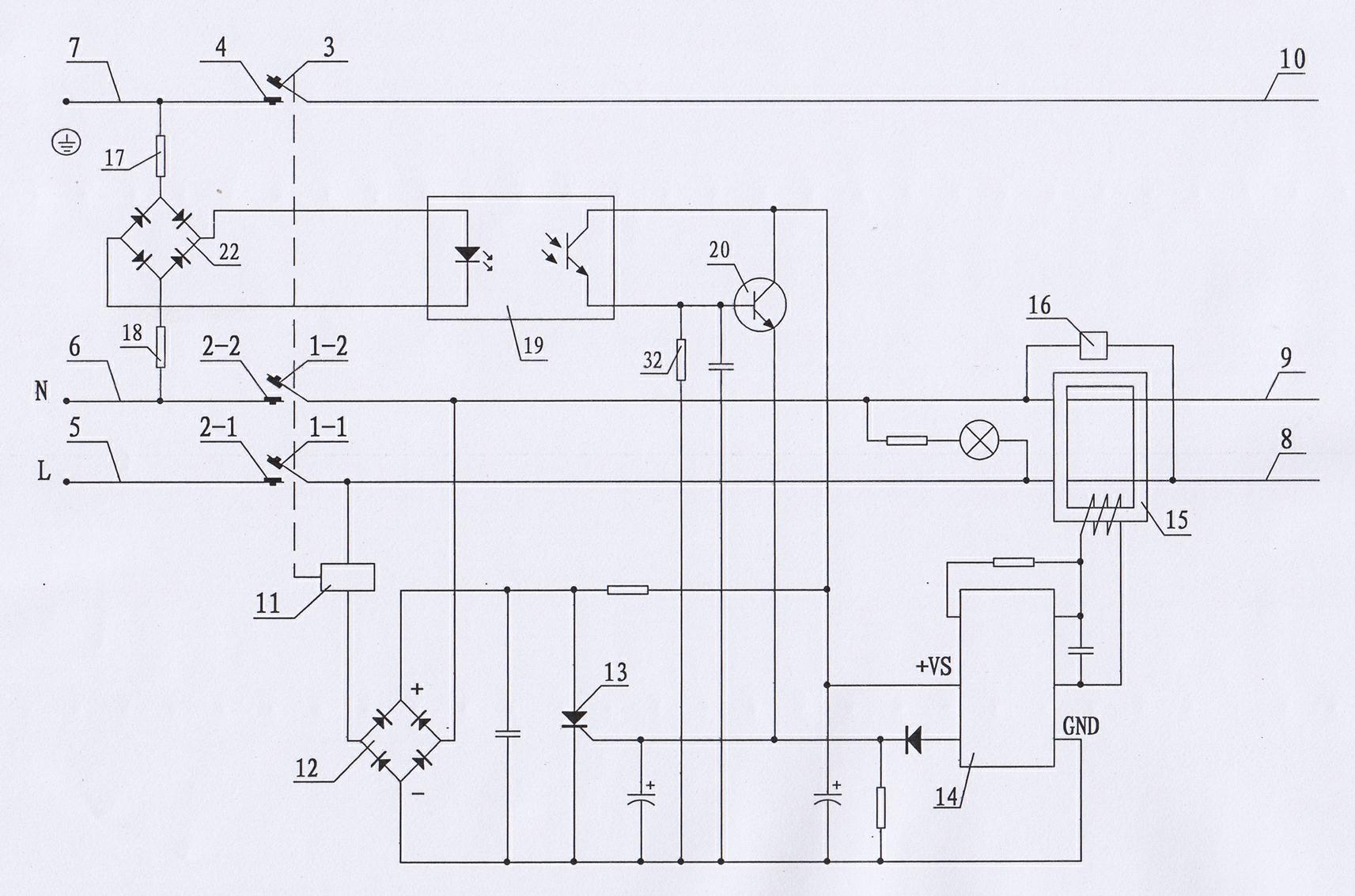

[0057] see image 3 As shown, compared with the first embodiment, the second rectification circuit 22 is added in this embodiment.

[0058] In this embodiment, it is composed of the first resistance-capacitance element 17, one input end and the other input end of the second rectification circuit 22, one input end and the other input end of the photocoupler 19, and the second resistance-capacitance element 18 The detection circuit is connected between the ground wire 7 and the neutral wire 6 at the power supply end, and one output end and the other output end of the second rectification circuit 22 are respectively connected to an input end and the other input end of the photocoupler 19 .

[0059] In this embodiment, the first resistance-capacitance element 17 is a resistor, and a capacitor or a combination of a resistor and a capacitor can also be used; the second resistance-capacity element 18 is a resistor, and a capacitor or a combination of a resistor and a capacitor can al...

Embodiment 3

[0065] see Figure 4 As shown, compared with the second embodiment, the present embodiment adds the first diode 23 and cancels the second rectifying circuit 22 in the second embodiment.

[0066] In this embodiment, the first diode 23, the first resistance-capacitance element 17, one input end and the other input end of the photocoupler 19, and the second resistance-capacitance element 18 form a detection loop connected to the ground wire 7 and the power supply end. Between the neutral line 6, one end of the first diode 23 is connected to the ground wire 7, the other end of the first diode 23 is connected to one end of the first resistance-capacitance element 17, and the other end of the first resistance-capacity element 17 is connected to the photocoupler 19. One input end is connected, the other input end of the photocoupler 19 is connected to one end of the second resistance-capacitance element 18 , and the other end of the second resistance-capacity element 18 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com