Compound vibration energy collector based on piezoelectricity and static electricity

A vibration energy harvesting and energy harvesting technology, which is applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems such as the decrease of energy harvesting efficiency of vibration energy harvesters, etc. achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

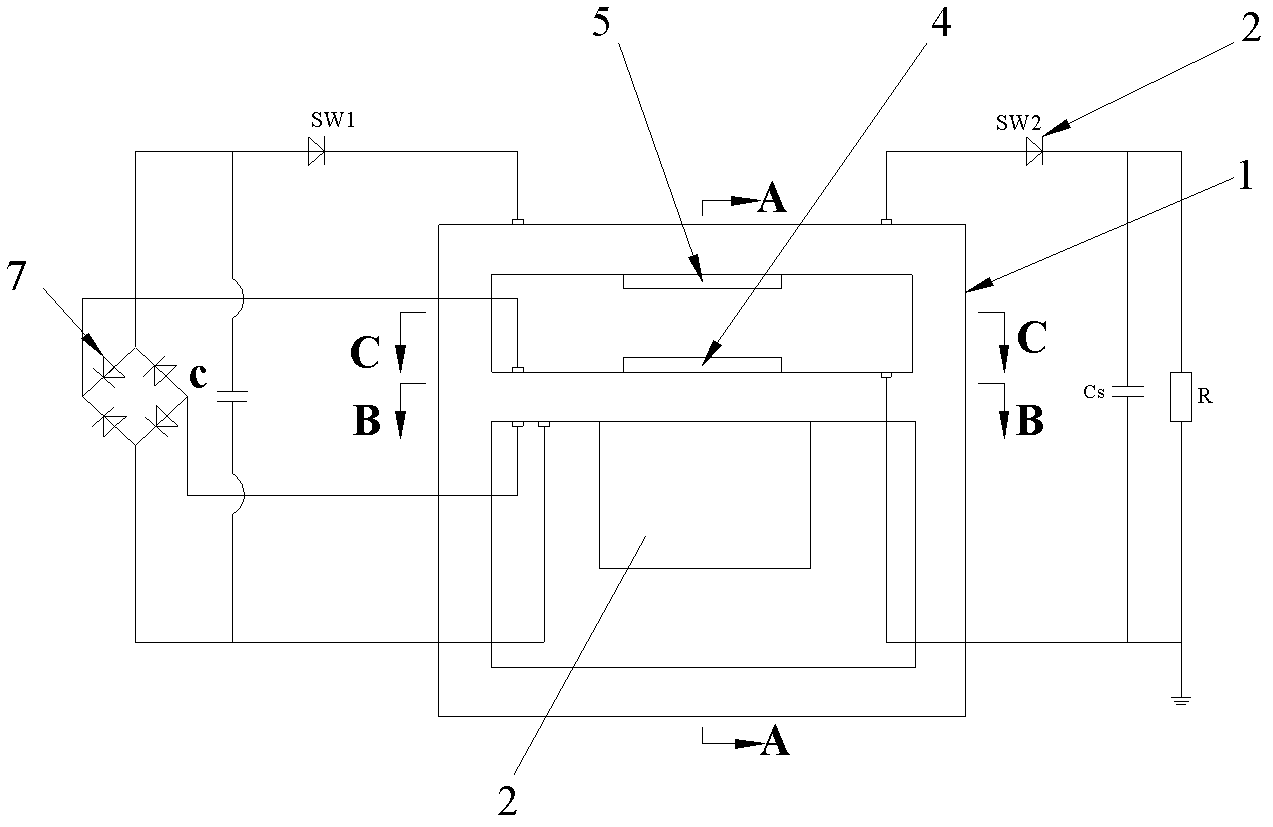

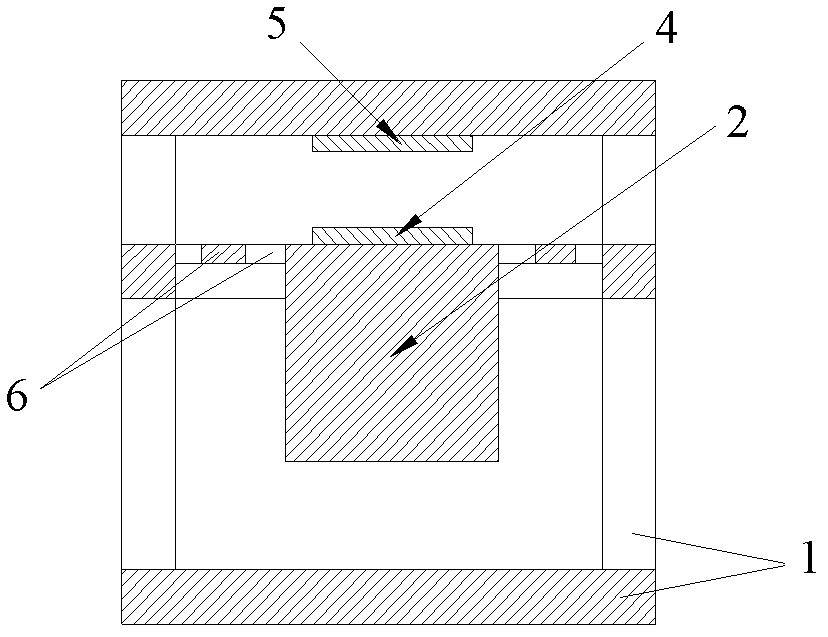

[0035] see Figure 1~4 , The present invention is provided with bracket 1, mass block 2, hollow connection plate 6, upper capacitor plate 5, lower capacitor plate 4, piezoelectric sheet group and energy harvesting circuit.

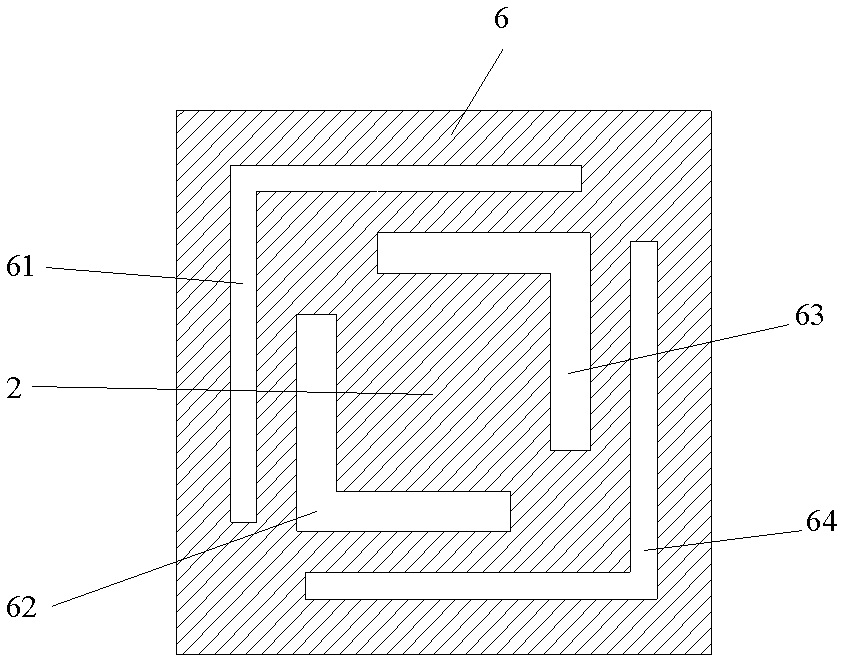

[0036] The support 1 is a rectangular frame. The mass block 2 is arranged in the center of the support 1 and is integrated with the support 1 through the hollow connecting plate 6 (the mass block and the hollow connecting plate are integrated with the rectangular frame). The hollow connection plate 6 is provided with four L-shaped hollow grooves 61-64, with the center line of the mass block 2 as the reference, and the hollow grooves surround the periphery of the mass block 2 inside and outside and are arranged symmetrically. The upper capacitor plate 5 is fixed on the upper part of the support 1 and is located above the mass block 2 . The lower capacitor plate 4 is fixed on the upper end of the proof mass 2 and faces the upper capacitor plate 5 . The pi...

Embodiment 2

[0038] see Figure 5 , similar to Embodiment 1, the only difference is that the four L-shaped hollow grooves 61 ′- 64 ′ provided on the hollow connection plate 6 ′ are staggered around the periphery of the mass block 2 , and are still arranged symmetrically.

Embodiment 3

[0040] see Figure 6 , similar to Embodiment 1, the difference is that the piezoelectric AC power source formed after each pair of electrodes is connected in series is directly connected to the external load 8 . The variable capacitor formed by the upper capacitor plate 5 and the lower capacitor plate 4 is powered by the capacitor plate starting power supply 9 (external power supply, such as a battery or externally connected mains power by an adapter). Figure 6 The rest of the labels in the figure 1 correspond to the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com