Smooth control method for torque of switched reluctance motor

A switched reluctance motor, smooth control technology, applied in the direction of torque ripple control, etc., can solve the problem of large torque ripple amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

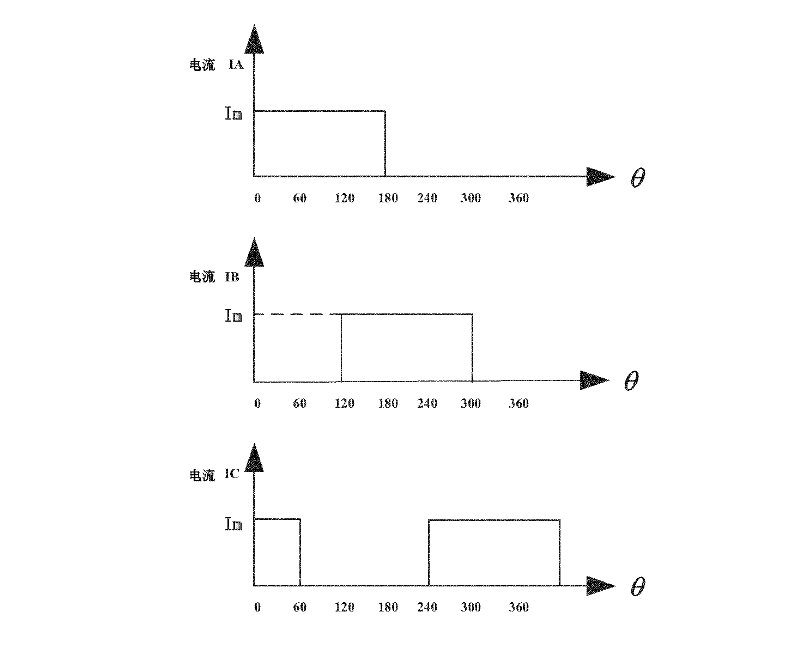

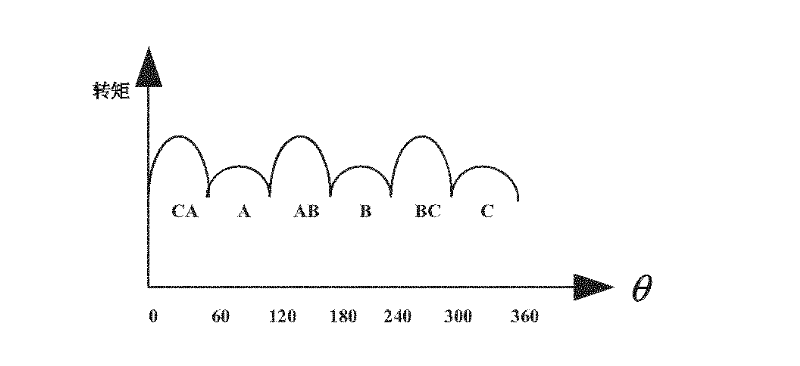

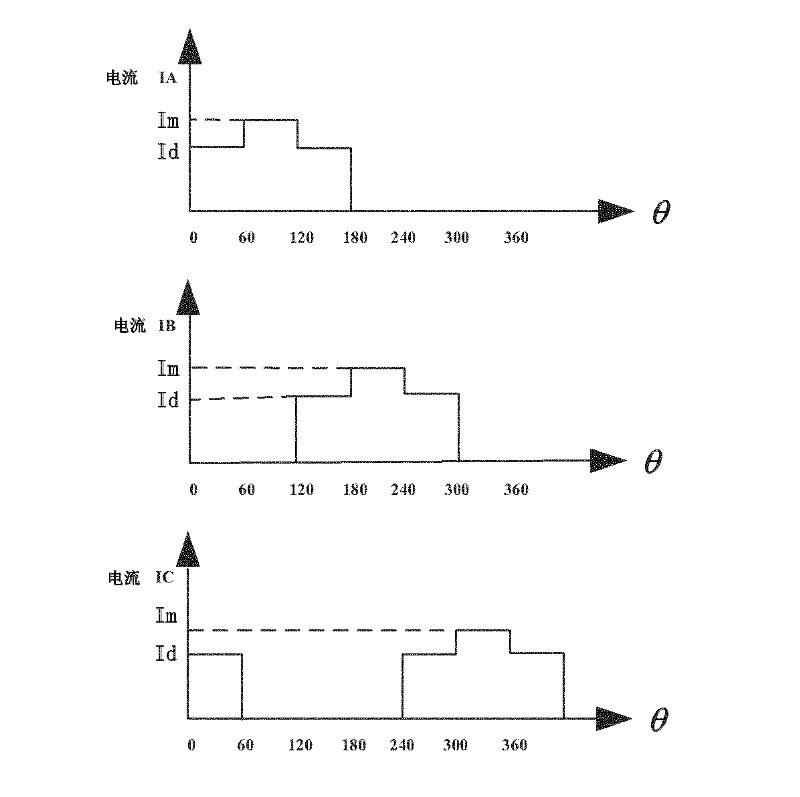

[0015] In the torque smoothing control method of the switched reluctance motor provided by the present invention, the control mode of the switched reluctance motor is the current chopping control mode, wherein when the two phases are turned on at the same time, the two phases in the current chopping control mode are The current in the conduction interval drops to the preset current amplitude respectively, so that the torque amplitude when two phases are turned on at the same time is close to the torque amplitude when one phase is turned on.

[0016] like image 3 , Figure 4 As shown, the speed of the switched reluctance motor is controlled by the current chopper control mode. When one phase is turned on, the current amplitude in the conduction interval is Im. When both phases are turned on at the same time, the two-phase conduction interval is The currents are respectively reduced to the preset current amplitude Id, so that the torque amplitude when the two phases are turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com