Method for processing oleyl phosphate in leaked oil on pavement by ozone

The technology of an oleyl phosphate ester and a treatment method, which is applied in the field of road traffic vehicle driving safety, can solve the problems of maintaining the friction coefficient of the road surface, incomplete treatment of the oleyl phosphate ester, etc., and achieves the effects of reducing slippage accidents and pollution-free cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

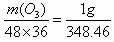

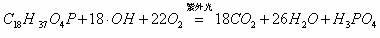

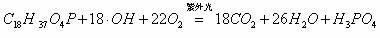

[0023] 1. Under ultraviolet light conditions, according to the reaction principle, adjust the pH value of the ozone aqueous solution, the temperature of oleyl alcohol phosphate and other factors to determine the most favorable reaction conditions. The specific steps are as follows;

[0024] ① Configure alkaline solutions with different pH values, inject the same amount of ozone, measure the concentration of hydroxyl radicals in the solution under the same environmental conditions, mix oleyl alcohol phosphate into ozone aqueous solutions with different pHs, mix and stir to make the hydroxyl radicals and Oleyl phosphate reacted, let it stand for 10 minutes, and measured the concentration of hydroxyl radicals and oleyl phosphate in the mixed solution again. It can be seen from experiments that the reaction between oleyl phosphate and hydroxyl radicals in ozone aqueous solution is the fastest when the pH is 10-12 fullest;

[0025] ②Keep the pH value constant, and experiment with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com