Ecological cement, its preparation and application

A technology of ecological cement and water glass, applied in cement production, etc., can solve problems such as groundwater waste, surrounding environmental impact, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

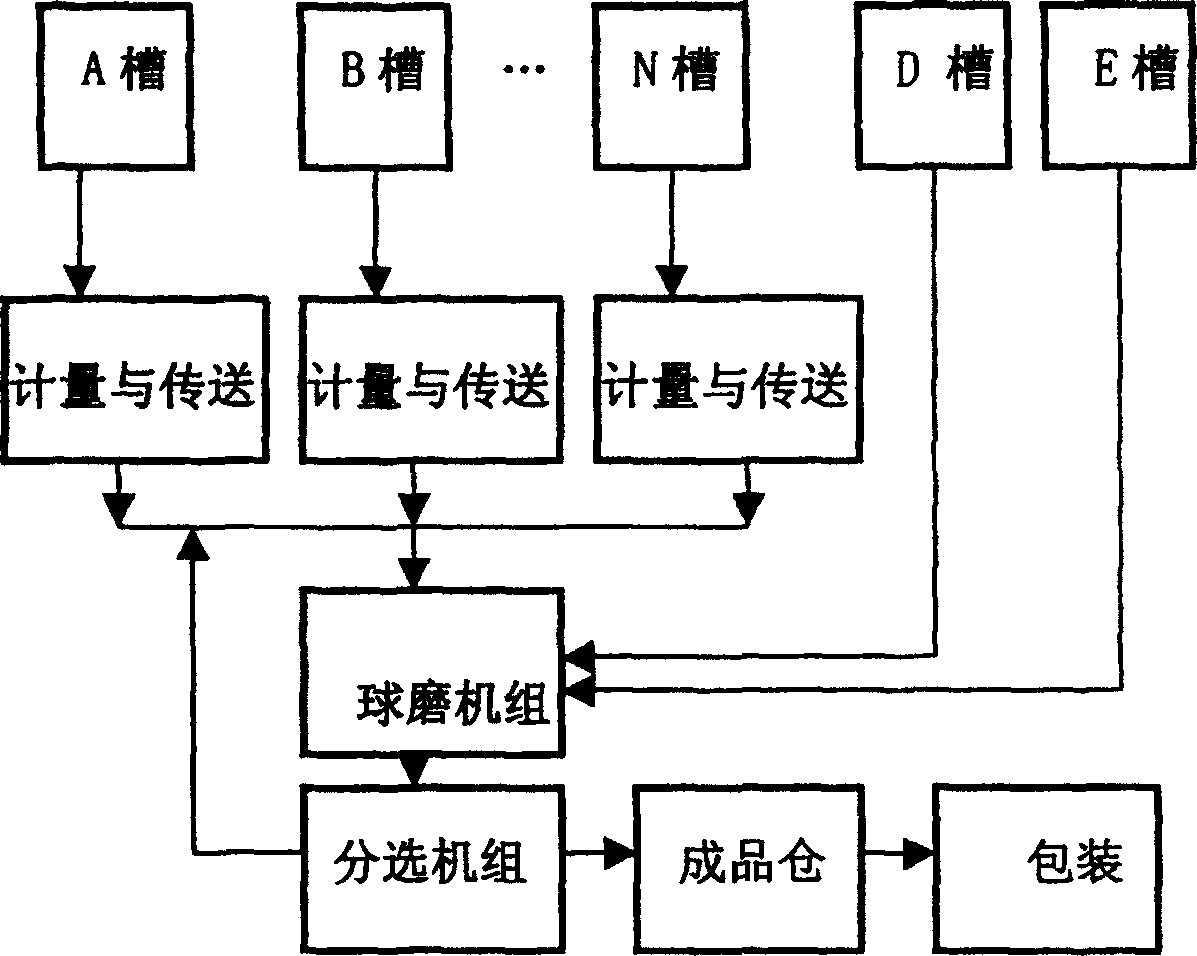

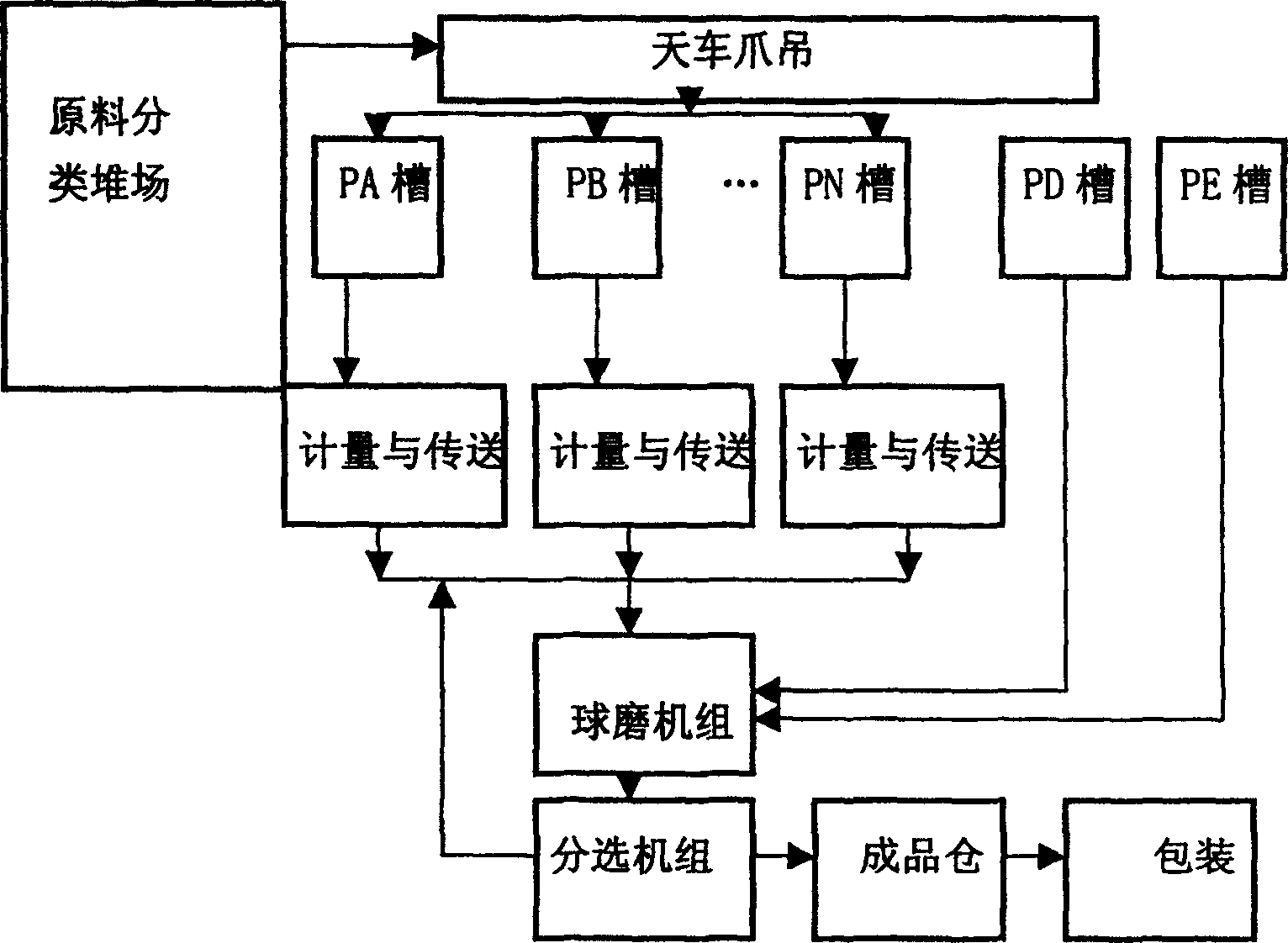

Method used

Image

Examples

Embodiment 1

[0103] Embodiment 1: Ecological cement and preparation method, calculate with the weight ratio of original material:

[0104] (1) Material F: fly ash 15%, water quenched slag 40%, shale (unroasted) 6.4%, material F additives: calcium sucrose 0.1%, sodium polyphosphate 0.2%, triethanolamine 0.3%, F The batching ratio of materials: molar ratio [Si] / [Ca]=1.0, [Si] / [Al]=2.25.

[0105] In-situ grinding of incoming materials is adopted, and various available materials are added to the grinding mill together with additives for grinding. The particle size is controlled at 3% of the 200 mesh sieve, and the specific surface area is 4300cm 2 / g.

[0106] (2) P material: slag 5%, lime 13%, phosphorus slag 14.3%, P material additives: sodium lignosulfonate 0.2%, active milk of lime 0.5%, sodium borate 0.2%. The batching ratio of P material: molar ratio [Si] / [Ca]=1.0, [Si] / [Al]=2.6.

[0107] The above-mentioned ingredients are processed by in-situ grinding of incoming materials, and var...

Embodiment 2

[0116] Embodiment 2: ecological cement and preparation method, calculate with the weight ratio of original material:

[0117] (1) F material: fly ash 5%, steel slag 10%, water quenching slag 39%, shale (roasting) 7%, F material additives: sodium lignosulfonate: 0.5%, sodium polyphosphate: 0.1%, Polyvinyl acetate 0.4%. , The batching ratio of F material: molar ratio [Si] / [Ca]=0.5, [Si] / [Al]=3.0.

[0118] The shale in material F adopts pre-roasting process, the roasting temperature is 800-900°C, and the roasting time is 1-2 hours.

[0119] Grind the above ingredients separately and enter into the mixer for mixing, firstly grind and then mix.

[0120] (2) P material: slag 5%, lime 13%, phosphorus slag 13%, P material additives: sodium polyphosphate 0.1%, active Al(OH) 3 1%, active milk of lime 0.9%. Grind the above ingredients separately and enter into the mixer for mixing, firstly grind and then mix.

[0121] Ingredients ratio of P material: molar ratio [Si] / [Ca]=0.5, [Si] / ...

Embodiment 3

[0133] Embodiment 3, cement, calculate with the weight ratio of original material:

[0134] Material F: 25% red mud, 40% water-quenched slag, 6% fly ash

[0135] F material additives: calcium dihydrogen phosphate 3%, sodium aluminate 1%

[0136] P material: 3% slag, 18% phosphorus slag

[0137] P material additives: active lime milk 0.1%, sodium lignosulfonate 0.1%, calcium sucrose 0.4%, calcium chloride 1.4%

[0138]Particle size control of material F: 3% remaining on 200 mesh sieve, specific surface area is 4300cm 2 / g;

[0139] Particle size control of material P: 4% remaining on 200 mesh sieve, specific surface area is 4900cm 2 / g.;

[0140] Ingredients ratio of F material: molar ratio [Si] / [Ca]=1.7, [Si] / [Al]=1.5

[0141] Ingredients ratio of P material: molar ratio [Si] / [Ca]=0.3, [Si] / [Al]=4.0

[0142] Material D: 4% of directing agent, solid content of material D: 78%.

[0143] Material D is made of highly active Al(OH) 3 , strong alkali, water glass and alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com