Framework of Y-shaped rolling mill with three rolls

A rolling mill frame and main frame technology, applied in the direction of metal rolling frame, metal rolling mill frame, metal rolling, etc., can solve the problems of inability to realize online adjustment, difficulty in installation and adjustment of rolls, poor force on the frame, etc. problem, to achieve the effect of light weight, easy cleaning and maintenance, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the invention are:

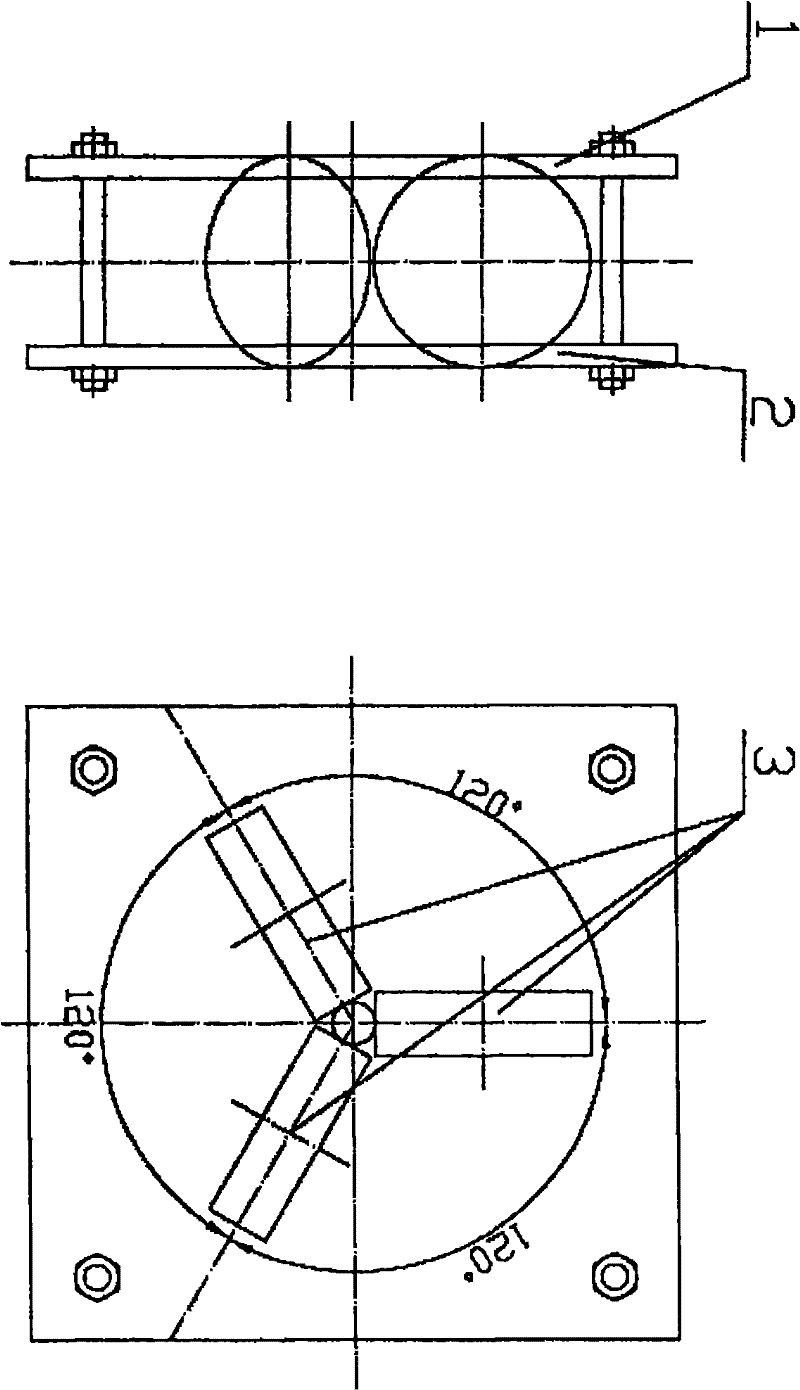

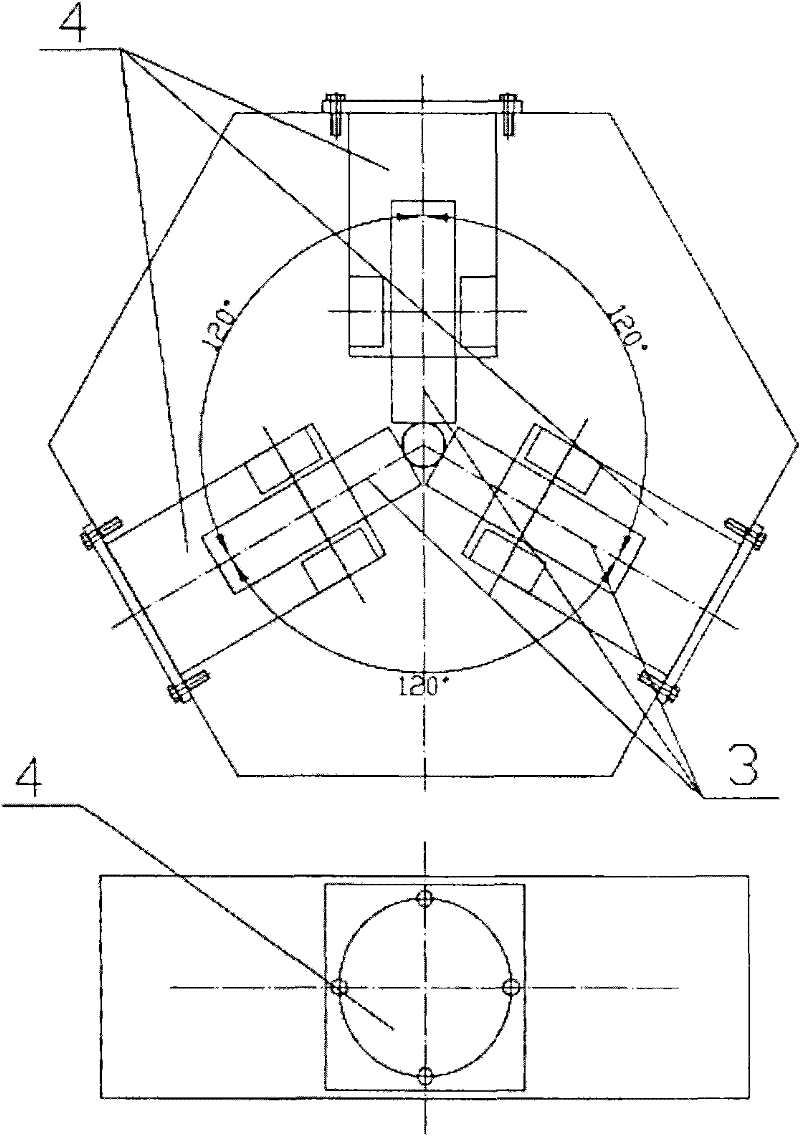

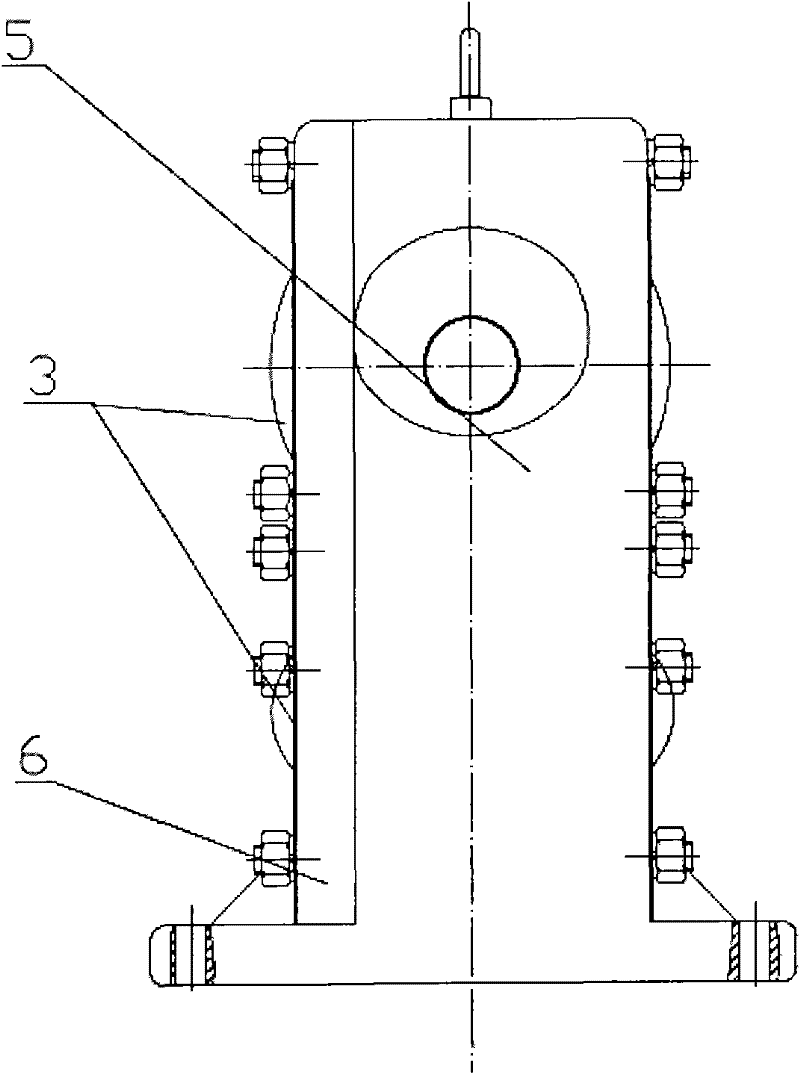

[0018] The three-roller Y-shaped rolling mill stand of the frame type structure is constructed by connecting the main frame 5 and the sub-frame 6 through bolts. window. The frame is an axisymmetric hexagon, with a hole for setting the roll pressing mechanism on the plane perpendicular to the radial direction of the roll, and a hole for introducing the roll transmission mechanism on the plane perpendicular to the axial direction of the roll. The sub-frame is a plane frame, accurately positioned with the main frame through positioning pins, and connected with the main frame by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com