Internal thread machining improved process

An internal thread processing and internal thread technology is applied in the field of internal thread processing and improvement of sheet materials, which can solve the problems of affecting processing quality, serious thread cracks, and high product rejection rate, so as to reduce the rejection rate, improve serious cracks, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

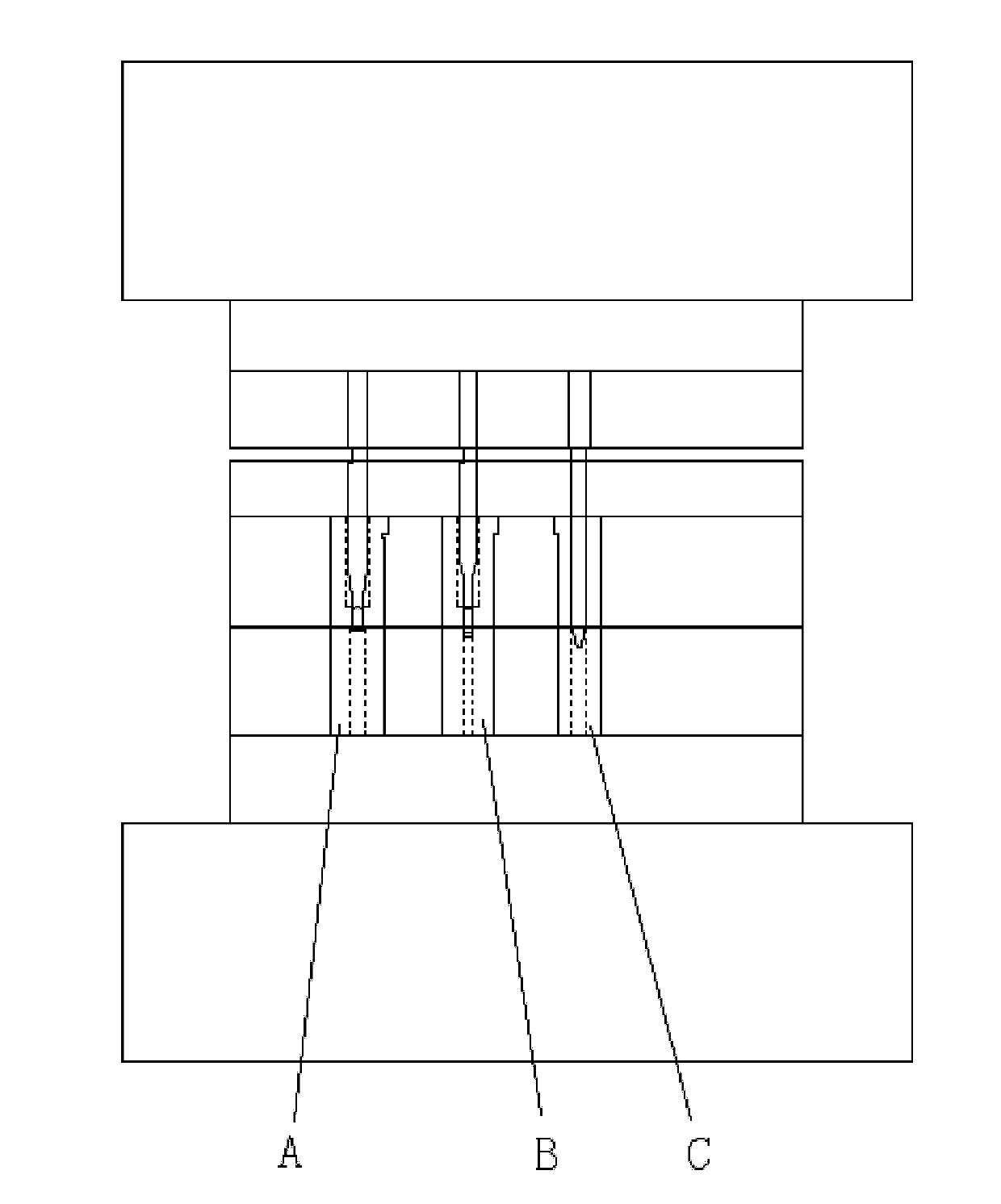

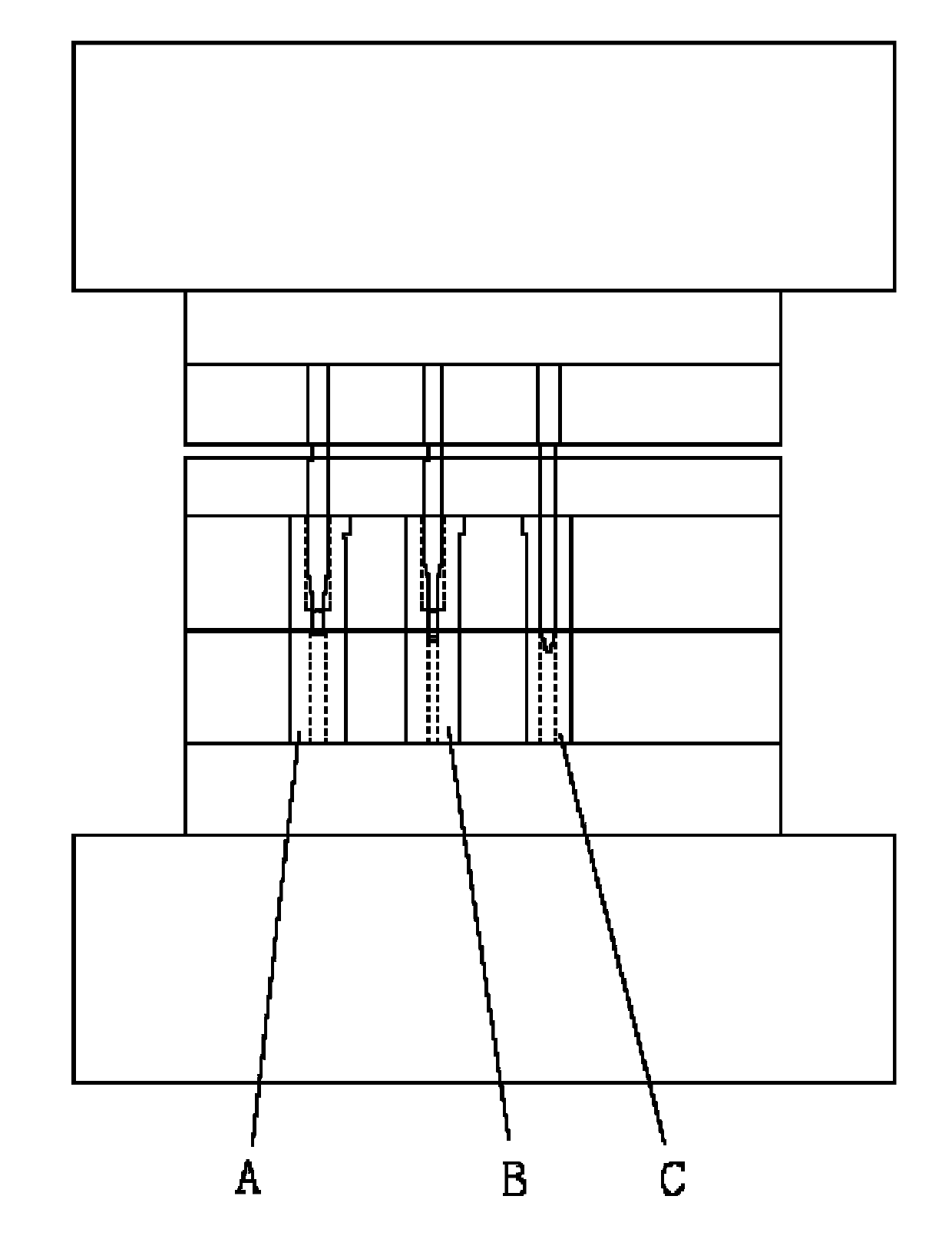

[0014] Embodiment: A kind of internal thread machining improvement process, concrete steps are as follows:

[0015] Step 1: Stretching pretreatment A: Stretch to a set depth on the place where the internal thread needs to be processed on the sub-processed plate, so that the tensile deformation of the plate will form a pit at the place where the internal thread needs to be processed;

[0016] Step 2: Pre-punching B: Punching to form a coaxial pre-punching hole at the stretching position;

[0017] Step 3: Germination C: Use a punch to perform germination on the pre-punched hole (that is, flanging, further stretching and deformation of the material) to form a columnar through hole without internal threads;

[0018] Step 4: Tapping: Use a tap to tap in the germinated columnar through-hole to form a threaded hole.

[0019] After the above steps, the material is stretched and deformed twice, the stress concentration inside the material is relatively small, and the wall thickness is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com