Rattan weaving machine

A rattan weaving machine and rattan weaving technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of laborious, unsafe operation, low work efficiency, etc., and achieve the effects of high rattan weaving efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

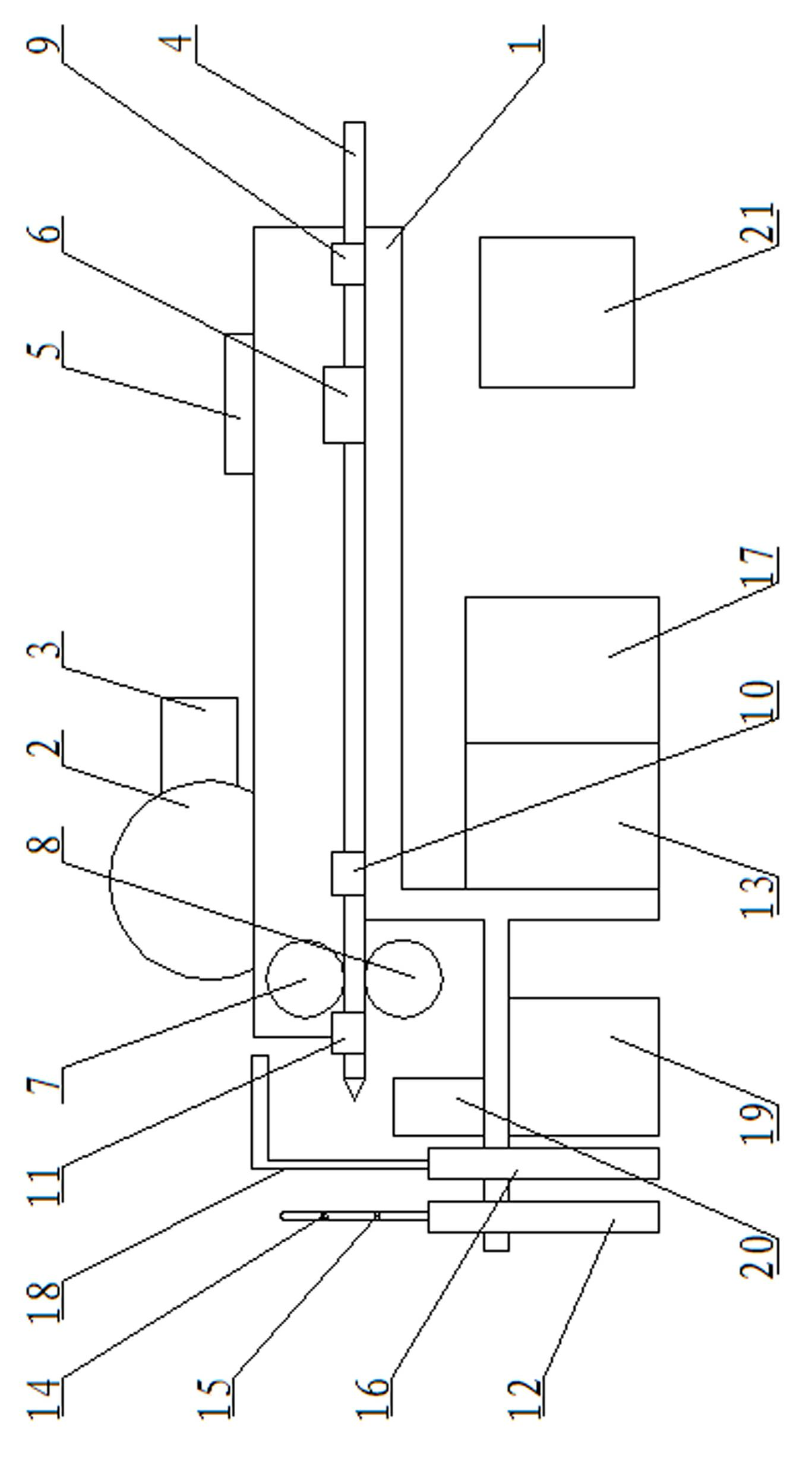

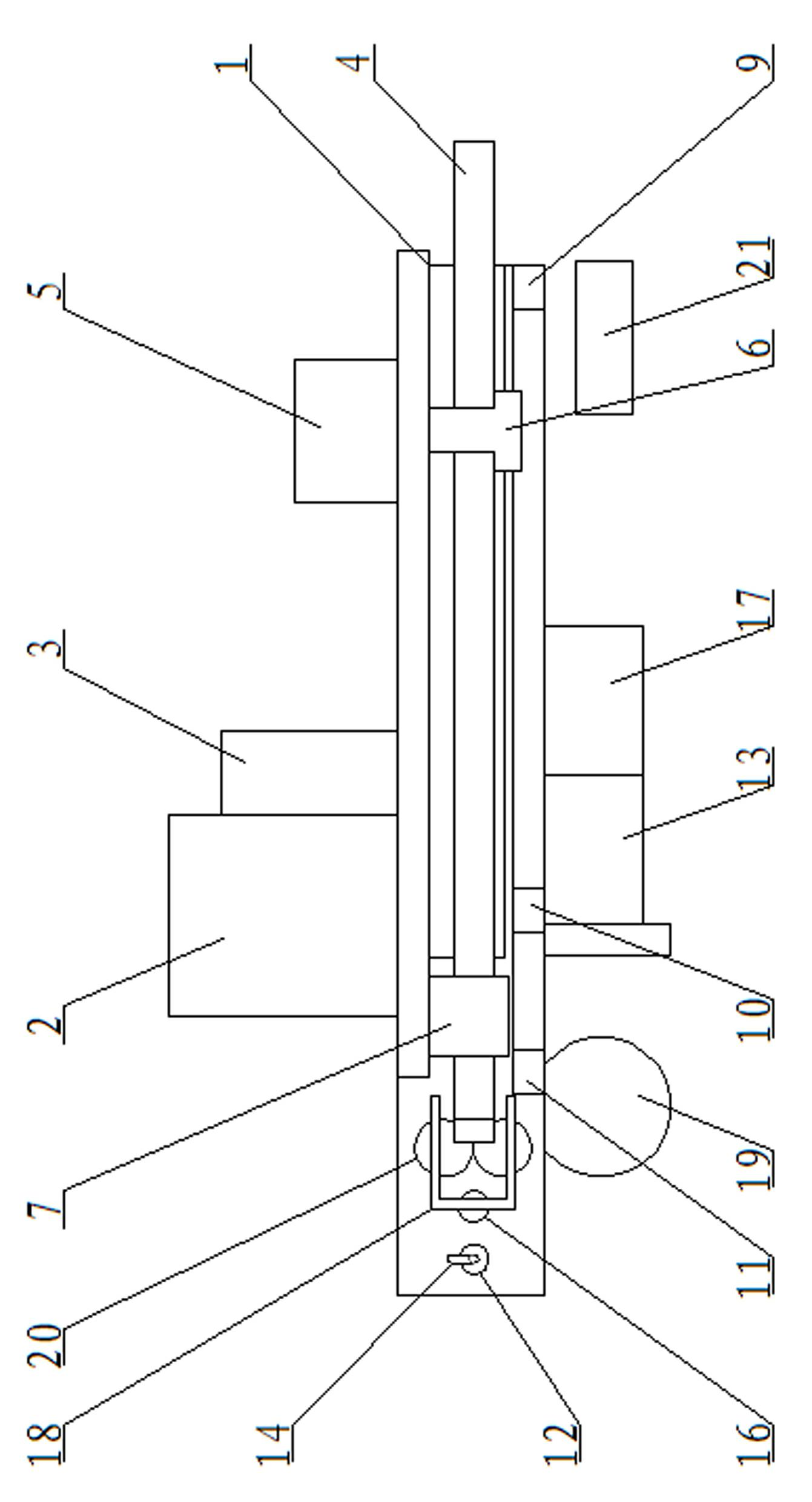

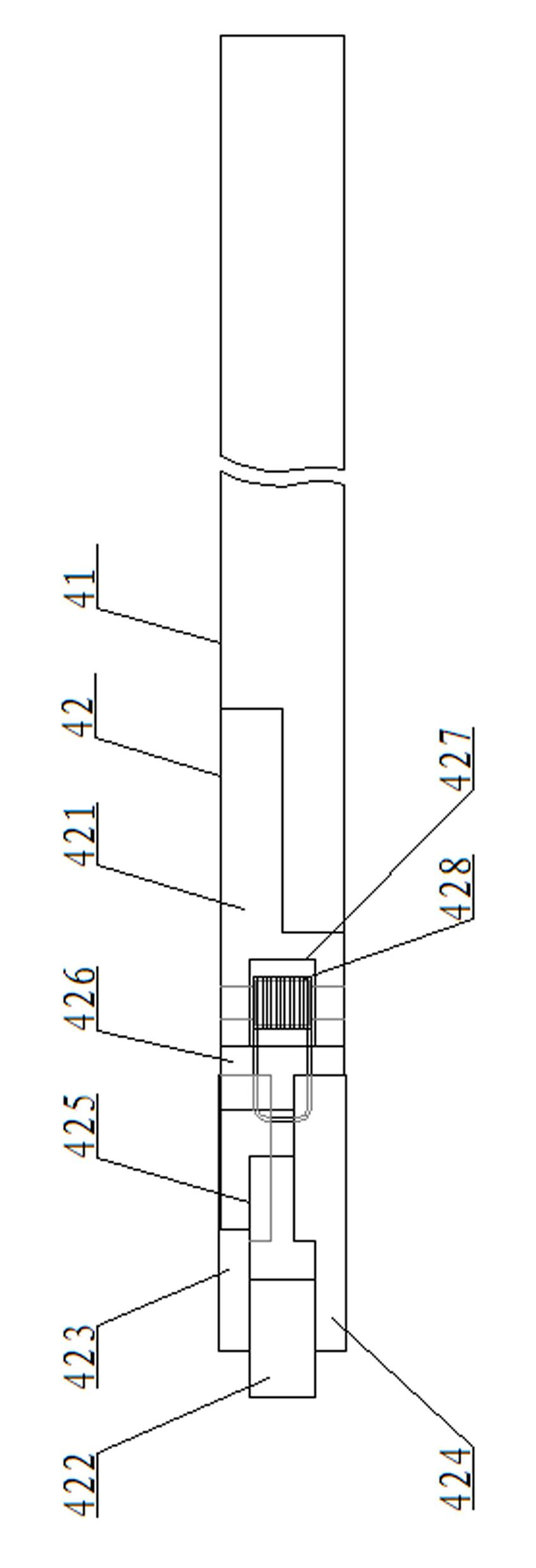

[0024] Figure 1-2 As shown, a rattan weaving machine includes a frame 1, a main motor 2, a reversing relay 3, a rattan weaving shuttle 4, a clamping cylinder 5, a chuck 6, an upper pressing wheel 7, a lower pressing wheel 8, and a retreat travel switch 9 , forward stroke switch 10, shuttle head reversing sensor 11, reversing cylinder 12, reversing solenoid valve 13, upper blowing head 14, lower blowing outlet 15, rattan pressing cylinder 16, rattan pressing solenoid valve 17, rattan pressing device 18 , secondary motor 19, rattan roller group 20 and controller 21. The rattan shuttle 4 is composed of a shuttle head 42 movably hinged at the front end of the shuttle body 41. The shuttle body 41 of the rattan shuttle 4 is slidably supported on the upper side of the frame 1. Backward travel switch 9, forward travel switch 10 and shuttle head reversing sen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap