Metal cup-cylinder composite nano structure array and preparation method thereof

A technology of composite nanostructure and metal nanostructure, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of low efficiency and high cost, and achieve the effect of good repeatability and large hot spot area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific embodiments and the description of the drawings.

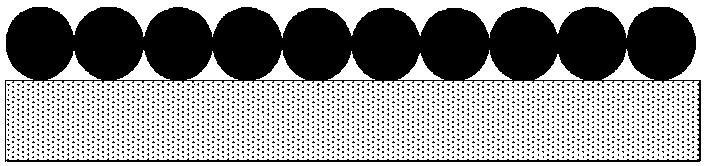

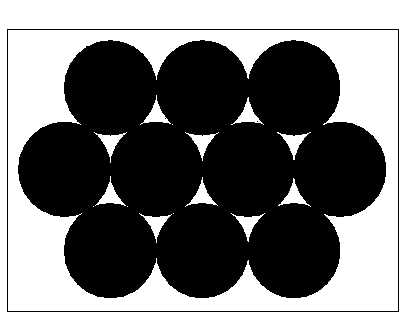

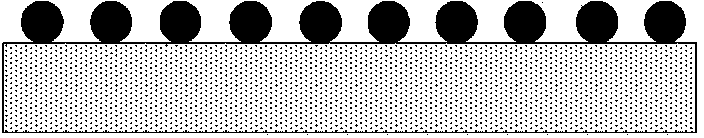

[0050] Kind of like Figure 14 The gold cup-pillar composite nanostructure array of the present invention shown includes a two-dimensional periodically arranged hexagonal array structure formed by gold nanostructure array units in an orderly manner. The gold nanostructure array unit is a gold cup-pillar composite nanostructure, The gold cup-pillar composite nano structure includes a cup-shaped gold nano outer wall 1, and the center of the cup groove surrounded by the gold nano outer wall is a cylindrical gold nano particle 2. In this embodiment, the distance d between the central cylindrical gold nano particles 2 of adjacent array units is 300 nm, the average thickness t and the average height a of the cup-shaped gold nano outer wall are 50 nm and 60 nm, respectively, and the cylindrical gold nano particles The average height h and the aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com