Method for com-culturing and improving hydrogen output by utilizing bacteria and chlamydomonas reinhardtii

A rhinestone and aerobic bacteria technology, applied in the field of biological hydrogen production, can solve the problems of easy pollution and easy pollution of other bacteria, and achieve the effect of increasing hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

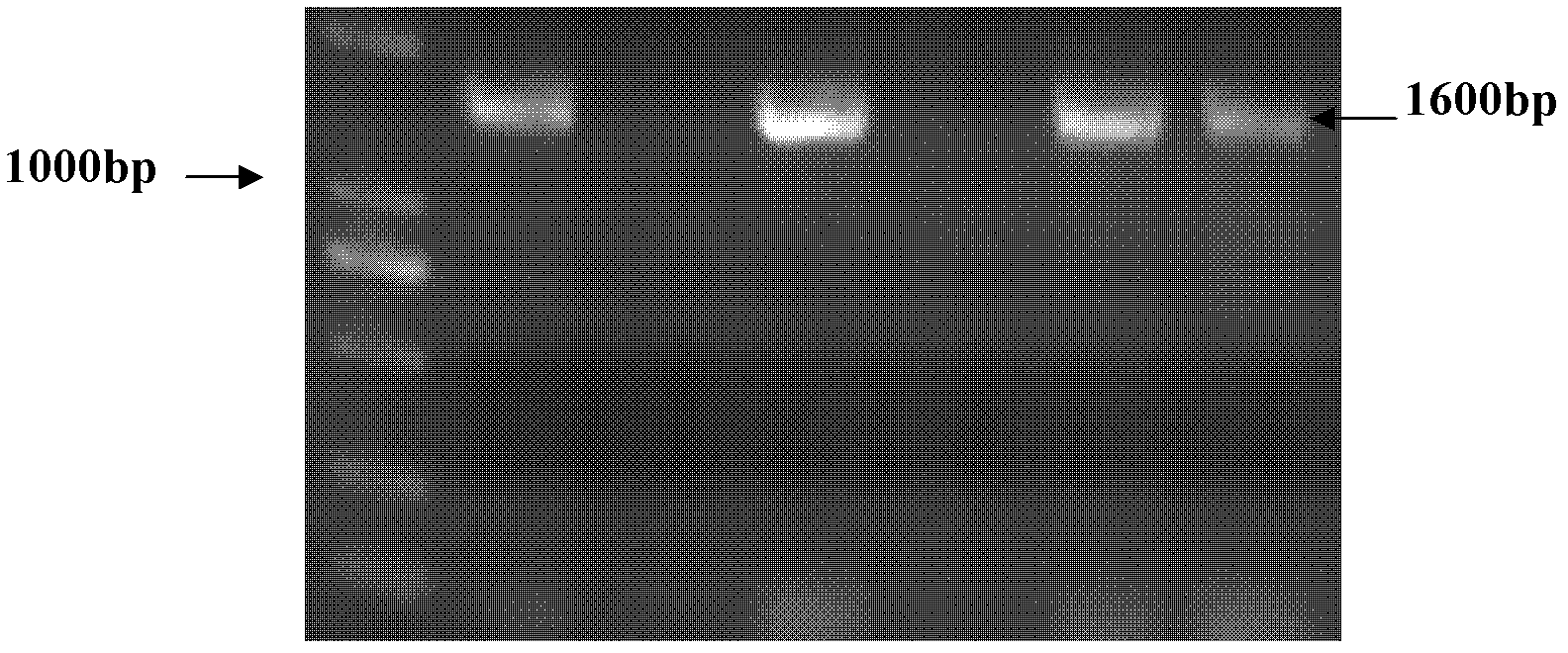

[0041] (a) Preparation of the bacterial genome: Take 2 mL of the bacterial solution in the logarithmic growth phase, add it to a sterile centrifuge tube, and centrifuge at 12,000 r / min for 5 min. Discard the supernatant, add 300 μL of 10 mg / mL lysozyme to the centrifuge tube containing the bacterial pellet, and incubate for 2 hours. Then add 15 μL of 10 mg / mL RNAase, 30 μL of 20 mg / mL proteinase K, and 100 μL of 10% SDS in sequence, mix well, and incubate at 65° C. for 45 minutes until clarified. Add 125 μL of 5M NaCl and 100 μL of 10% CTAB and incubate at 65° C. for 30 minutes to fully lyse the cells and remove polysaccharides. Then follow the routine steps for extracting DNA with phenol extraction, ethanol precipitation of DNA, and finally dissolve the DNA in pure water for later use.

[0042] (b) Primer design: According to the literature, the general primers for bacterial 16S rDNA gene amplification were selected: 27F (5'-AGAGTTTGATCCTGGCTCAG-3') and 1492R (5'-GGTTACCTTG...

Embodiment 1

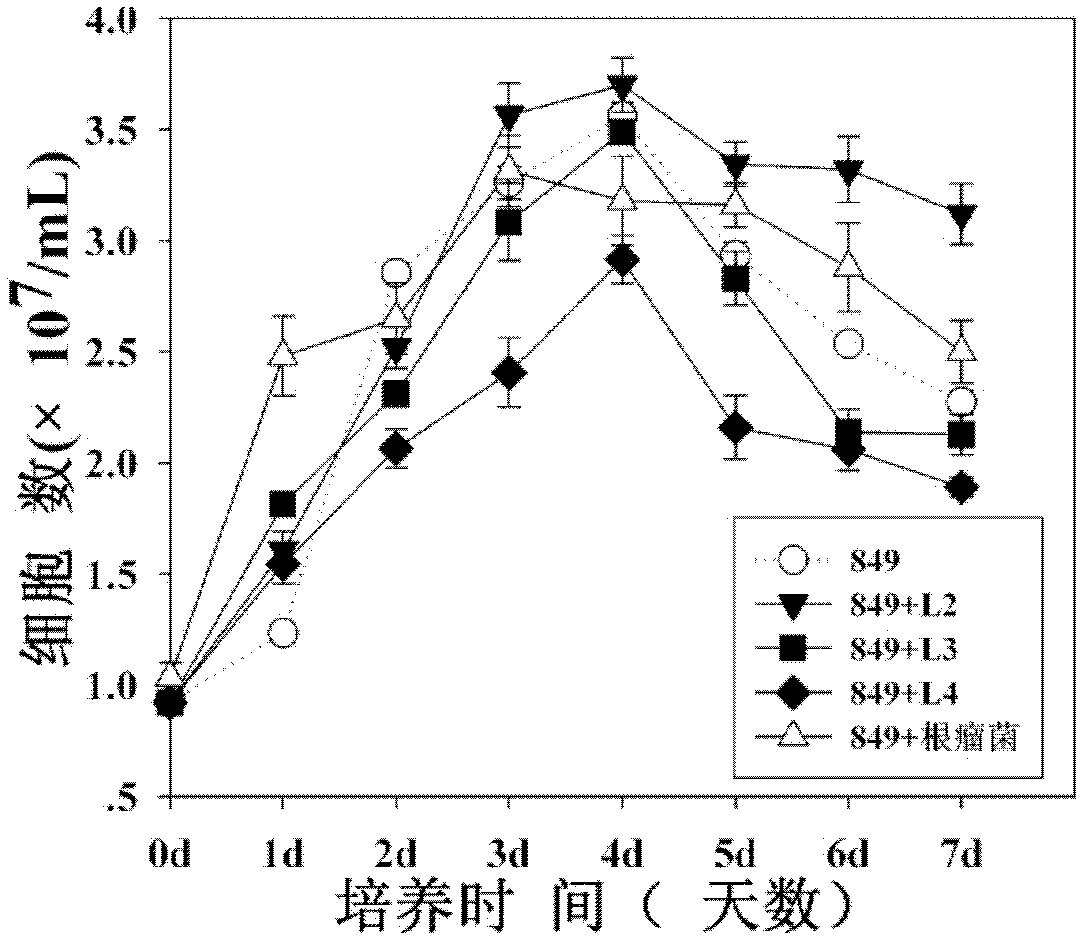

[0060] Embodiment 1 Chlamydomonas reinhardtii culture

[0061] Chlamydomonas reinhardtii has fast growth rate, low culture cost and high hydrogenase activity, and is a representative species of microalgae for photosynthetic hydrogen production. In order to make the experiment easier to operate, the present invention prefers Chlamydomonas reinhardtii species cc849 which lacks the cell wall.

[0062] ①Normal culture conditions of Chlamydomonas reinhardtii: According to "The Chlamydomonas Sourcebook: a comprehensive guide to biology and laboratory use. New York: Academic Press. 1989" edited by Harris, the optimal condition is 25±1°C, and the intensity of sunlight (100-200 μmol photons m -2 the s -1 ); liquid culture is in 50~100ml Tris-Acetate-Phosphate (TAP) medium, initial pH7.2, horizontal shaker speed 100~130rpm, every 5~6 days 1% inoculation subculture; Solid TAP plate culture medium contains 1.5% agar powder, the preservation and purification of the algal species is to p...

Embodiment 2

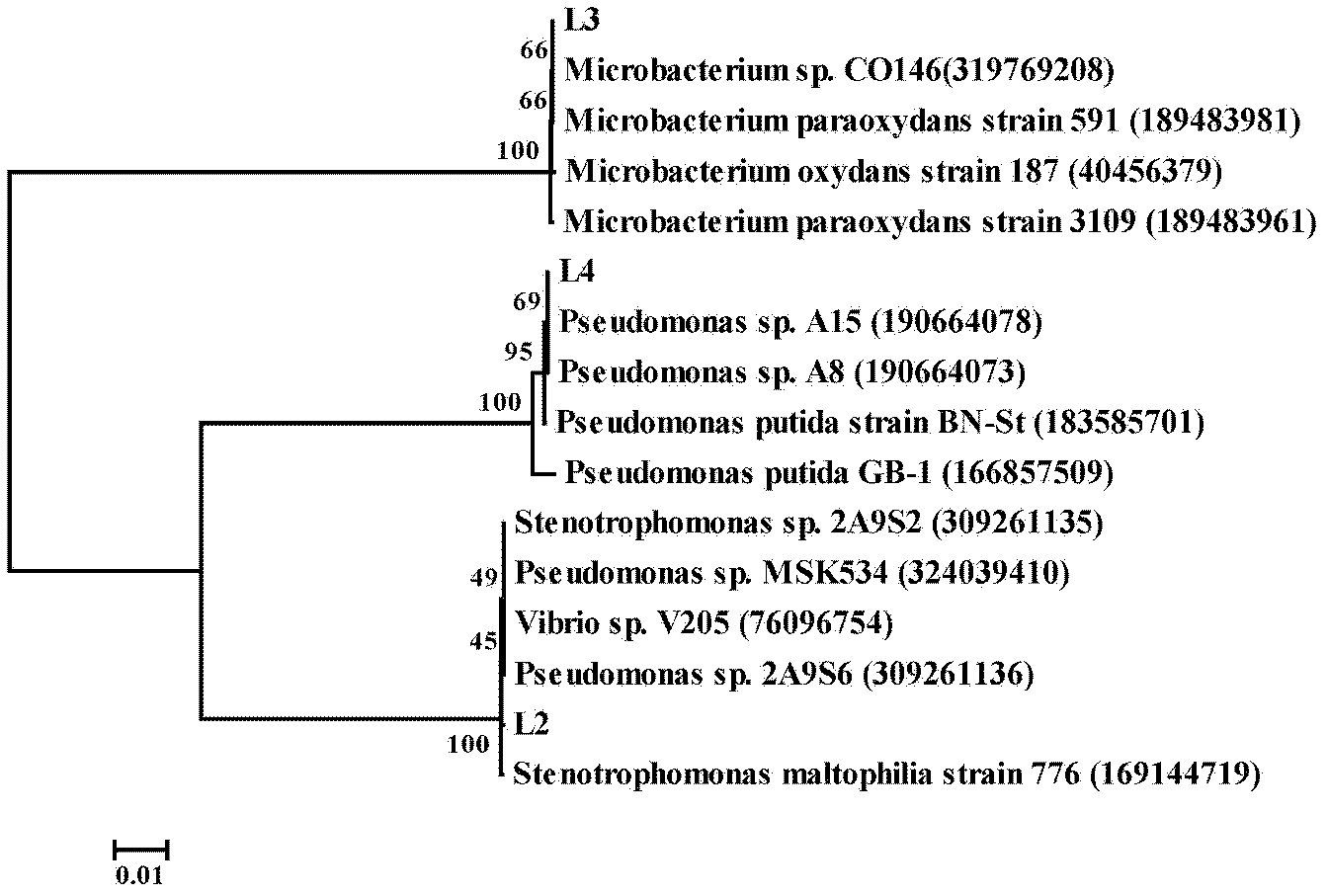

[0065] Example 2 Isolation and Identification of Chlamydomonas Symbiotic Bacteria

[0066] ① Isolation, purification and cultivation of Chlamydomonas symbiotic bacteria:

[0067] Take 1 mL of Chlamydomonas culture solution contaminated with bacteria in different growth stages and dilute it with sterile double distilled water for 10 -1 、10 -2 、10 -3 Three concentration gradients were applied sequentially to TAP medium, TAP+ Escherichia coli medium LB (TAP medium [7] and E. coli LB medium [8] According to the volume ratio of 1:1 mixed) and YEM medium [9] On solid plates, culture them at 25°C, 28-30°C, and 37°C respectively. After colonies grow out, pick a single colony and subculture in the corresponding liquid medium.

[0068] Using TAP+LB, YEM and TAP three kinds of medium plates, the bacteria that live with Chlamydomonas reinhardtii cc849 were preliminarily isolated. As a result, two single colonies with different characteristics were isolated on the TAP+LB mixed medium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com