Sputtering device

A technology for sputtering and workpieces to be plated, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve problems such as low coating efficiency and limited number of workpieces, improve coating efficiency and improve space utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

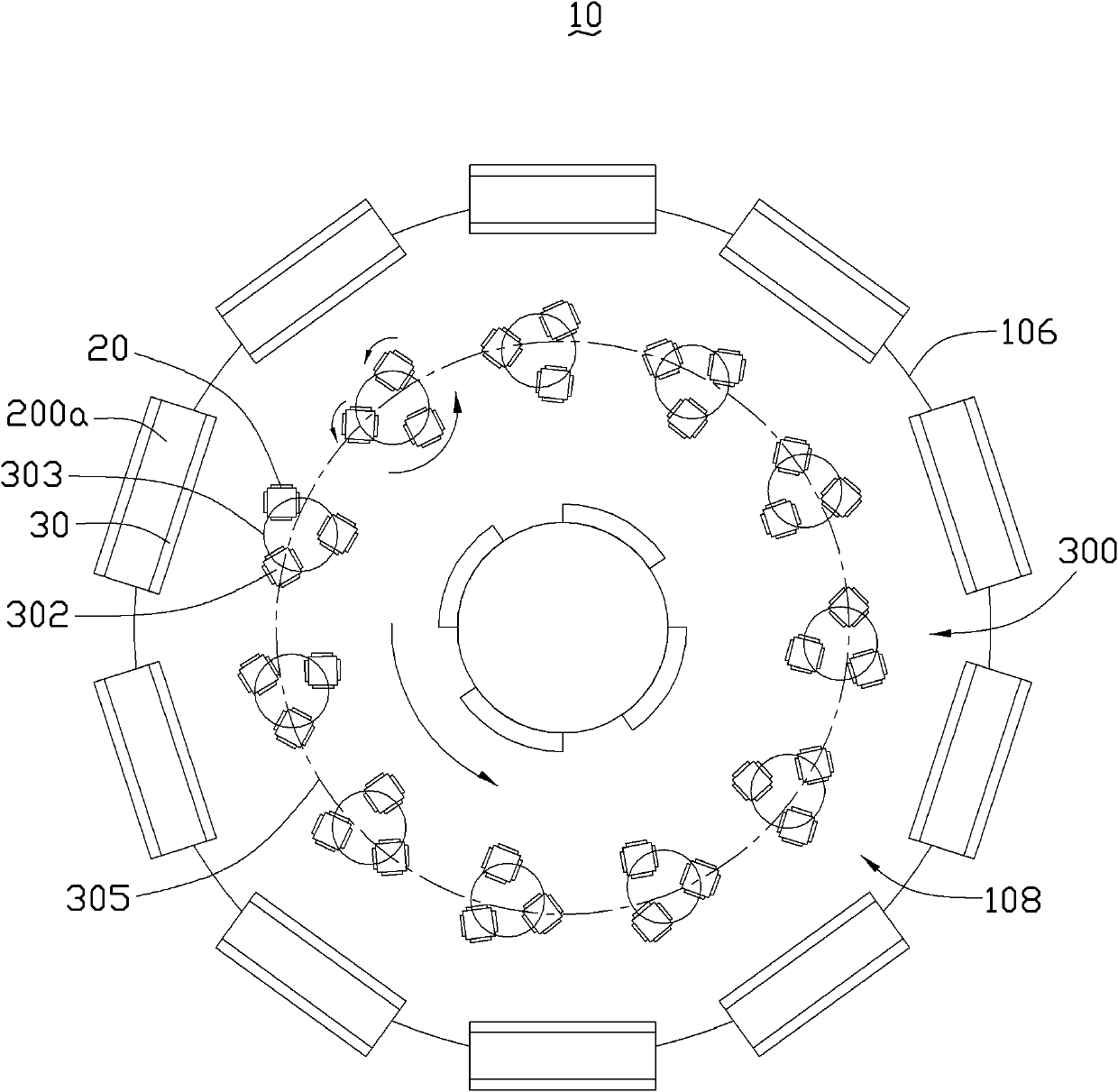

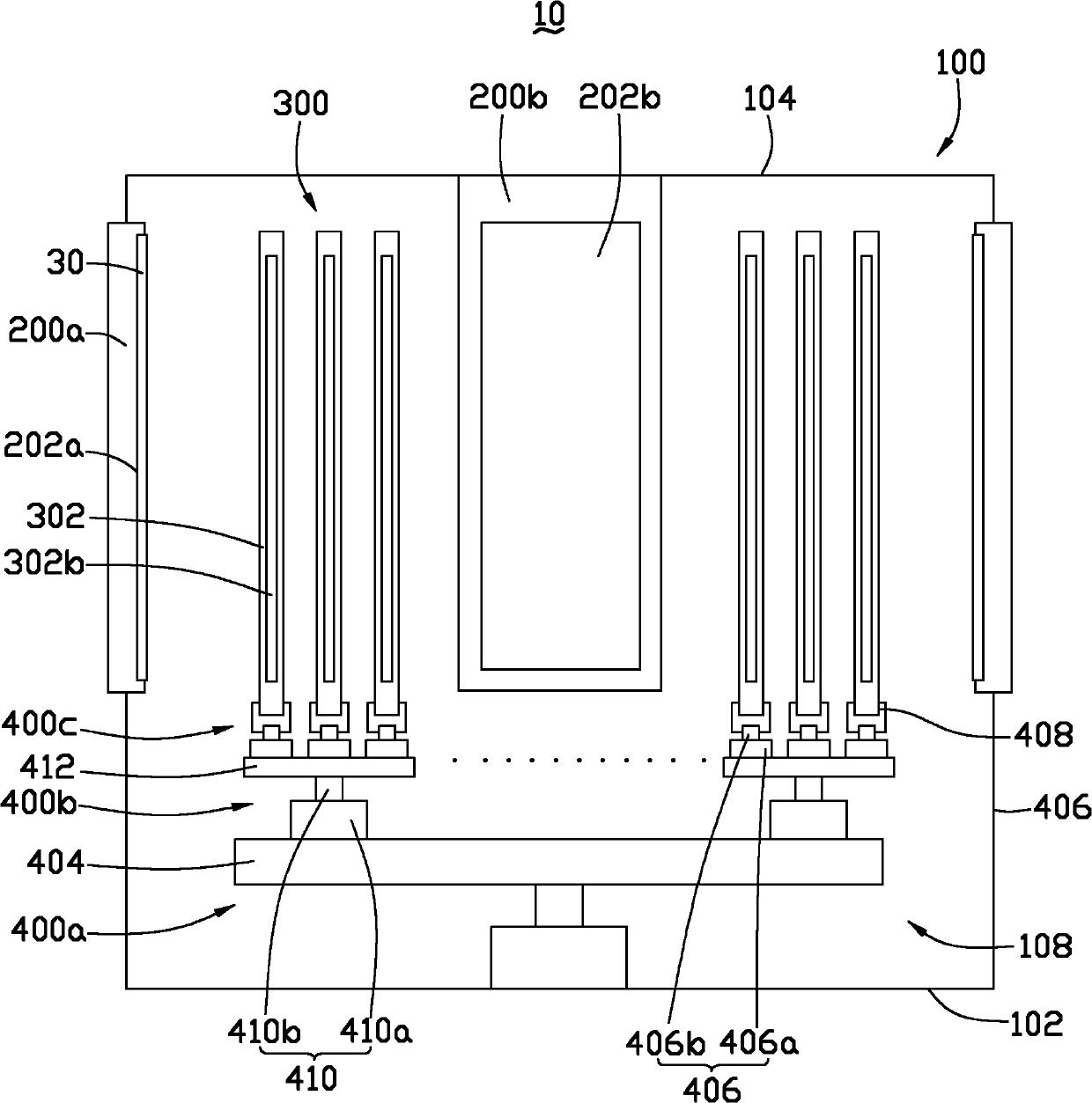

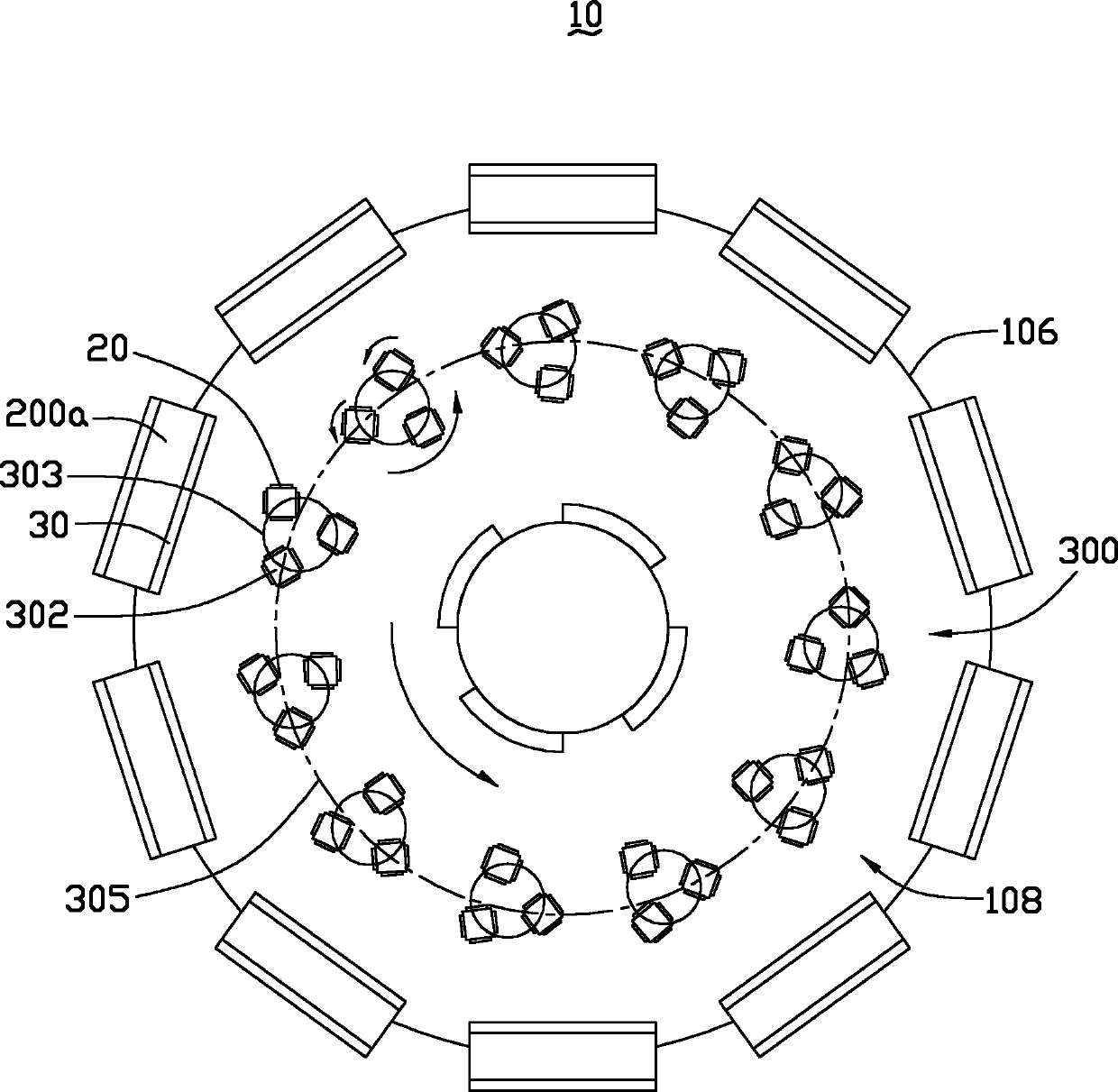

[0041] Please refer to figure 1 and figure 2 , The sputtering device 10 of the preferred embodiment of the present invention includes a housing 100, a plurality of first target holders 200a, a second target holder 200b, a plurality of rod groups 300, a first driver 400a, and a plurality of second driver 400b, and a plurality of third driver groups 400c.

[0042] The housing 100 defines a cavity 108 . Specifically, the housing 100 includes a bottom plate 102 , a top plate 104 and a side wall 106 . The bottom board 102 is opposite to the top board 104 . The side wall 106 connects the bottom board 102 and the top board 104 . Bottom plate 102 generally faces downward. The bottom plate 102 , the top plate 104 and the side walls 106 define a cavity 108 . The cavity 108 is cylindrical and used to define a space for sputtering coating.

[0043] A plurality of rod groups 300 are accommodated in the cavity 108 , arranged in parallel and arranged to form a second circle 305 . Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com