Computerized flat knitting machine

A technology of computerized flat knitting machines and needle beds, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of not being easy to relax, large frictional resistance, waste of driving motor power, and large frictional resistance, etc., so as not to occupy space , Low manufacturing cost, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

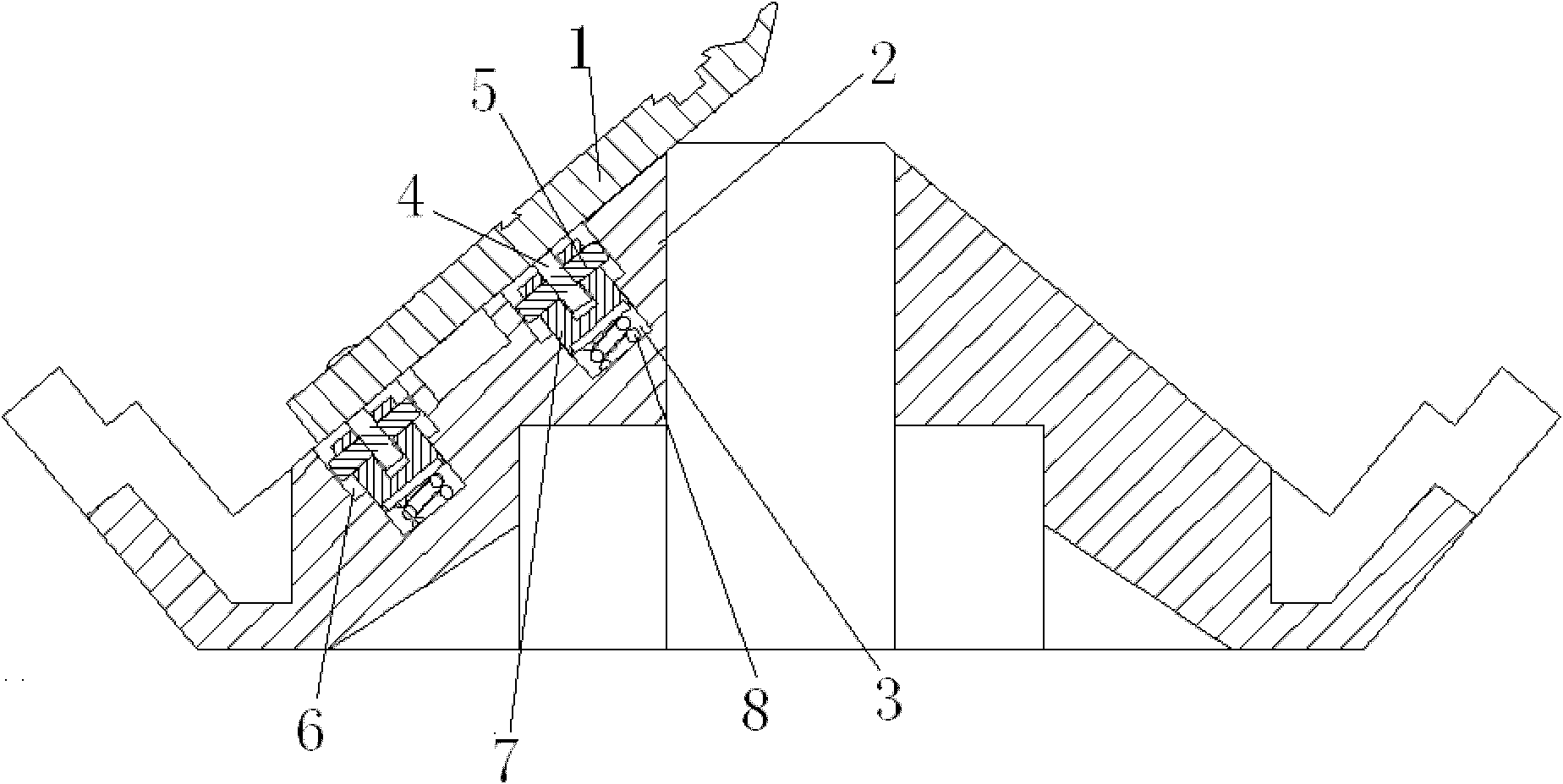

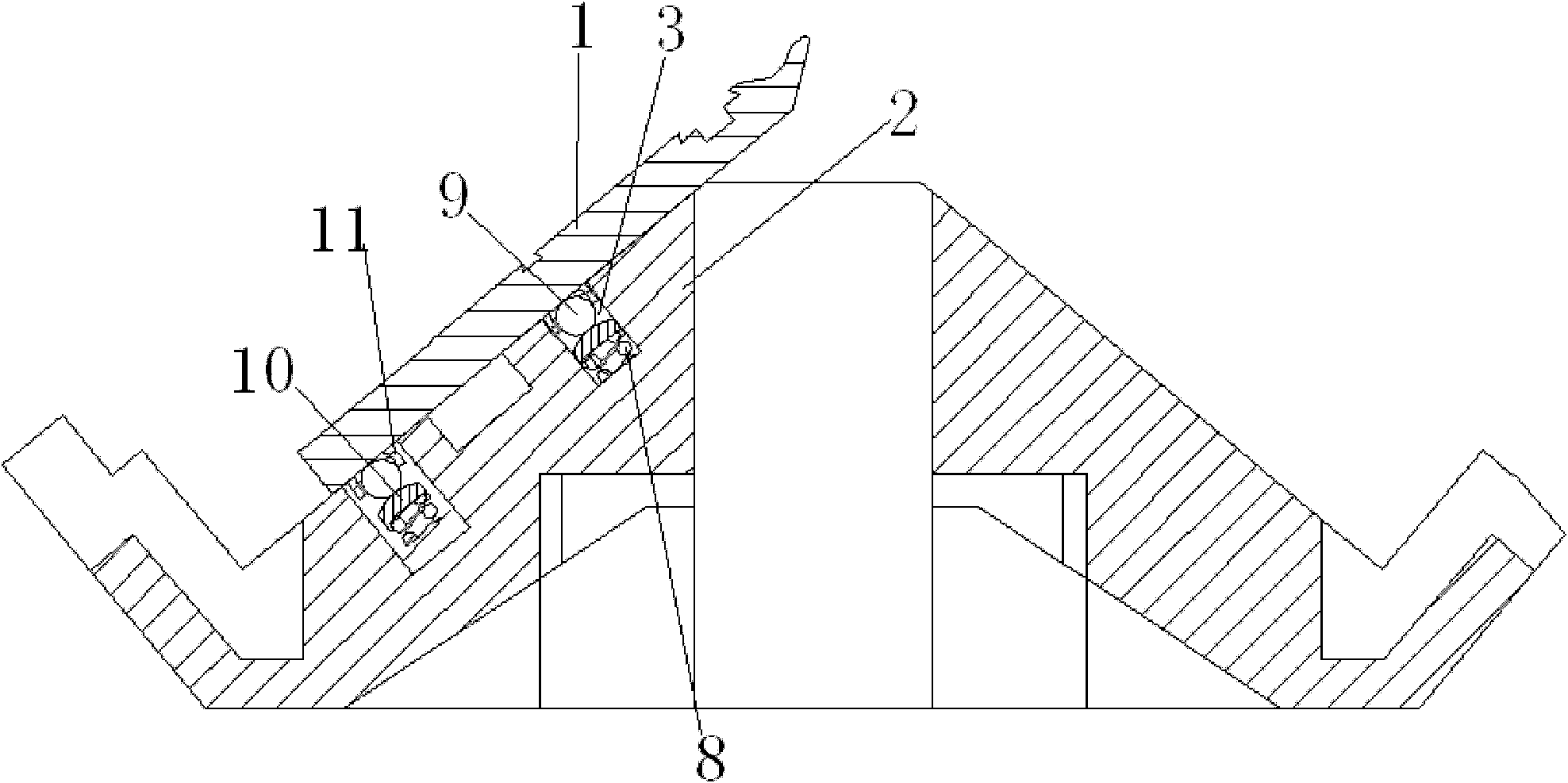

[0019] The computerized flat knitting machine of the present invention comprises a needle bed base and a needle bed on the needle bed base. The needle bed base 2 is provided with a rolling device which facilitates the reciprocating movement of the needle bed 1 on the needle bed base 2 .

[0020] The quantity of rolling device can be set according to the actual situation, generally speaking, one is respectively arranged at the two ends and the middle of the needle bed seat 2 and just can reach the purpose of the present invention.

[0021] figure 1 Shown is a schematic view of an embodiment of the rolling device of the present invention, the rolling device includes a bearing 4, the bearing 4 is arranged on a bearing frame 7, and the bearing frame 7 is installed in the installation groove 3 provided on the needle bed base 2 , the outer ring surface of the bearing 4 is in contact with the back of the needle bed 1 .

[0022] The rolling direction of the bearing 4 is consistent wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com