Hinge for a panel door, in particular for a cooling cupboard

A panel and hinge technology, applied in the hinge field, can solve the problems of deterioration during use, unsatisfactory sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

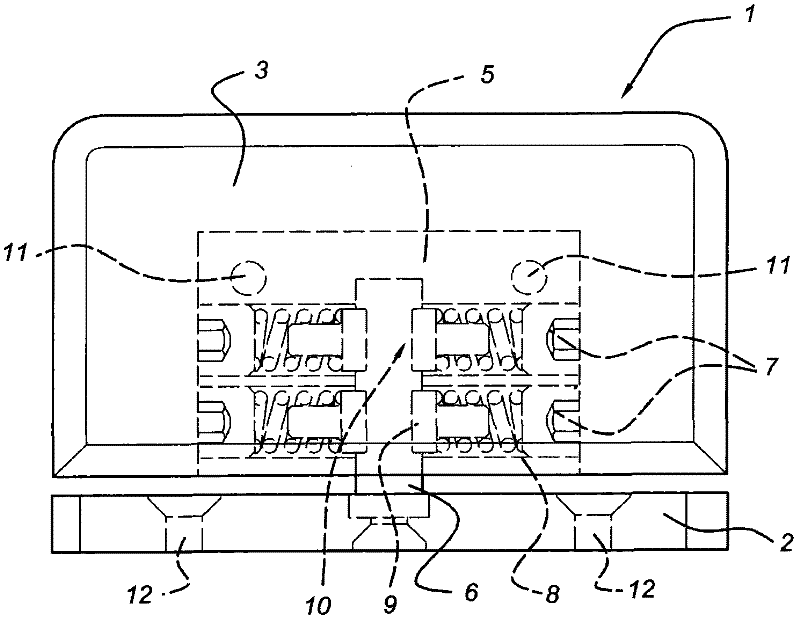

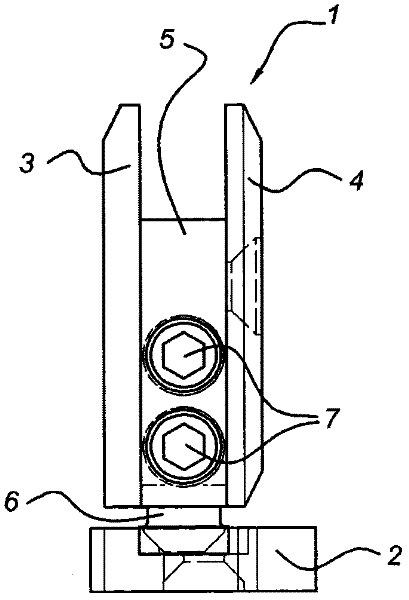

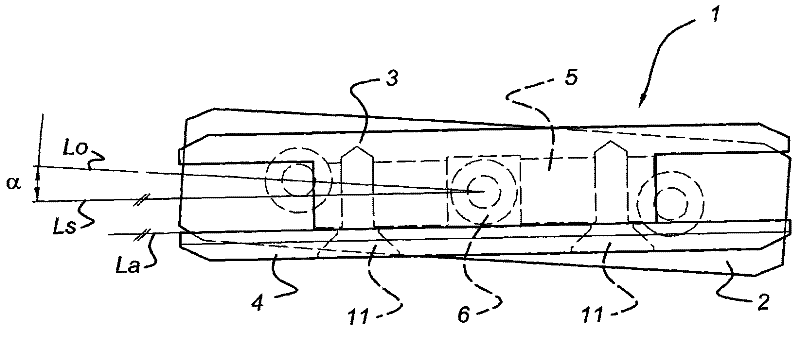

[0026] figure 1 A front view of an embodiment of a hinge 1 for a panel such as a glass door is shown. figure 2 shown in side view figure 1 the hinge, and image 3 shown in top view figure 1 hinge. It should be clear that such a hinge can have many embodiments, as shown in the prior art mentioned above, which will not be enumerated. exist Figure 1-3 In the embodiment shown, the hinge 1 has a sill / lintel attachment 2 which is attachable to a fixed enclosure, which in many cases is a sill or lintel. Two holes 12 are provided in the sill / lintel attachment 2 , here in the form of a plate, through which the sill / lintel attachment 2 can be attached to the lintel or sill, for example by screws.

[0027] Furthermore, the hinge 1 also has two clamping parts 3 and 4 which in this case are connected to each other. Panels such as glass panels may be clamped between these clamps. In this case, the clips are connected to each other by bolts 11 , for example countersunk screws formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com