Pipe-connected discharge valve capable of removing scab

A discharge valve and pipe connection technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of easy accumulation and scarring at the discharge outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

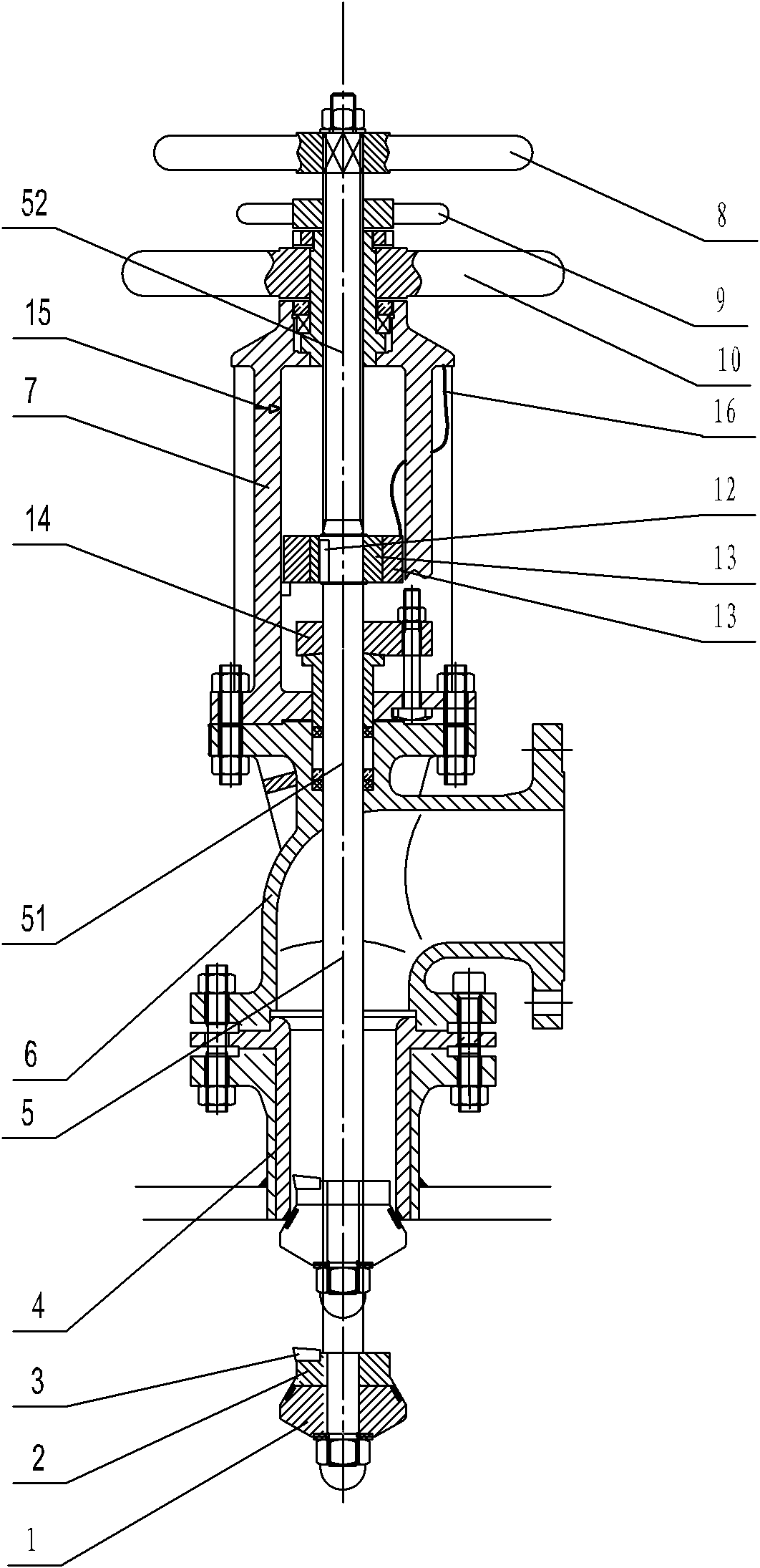

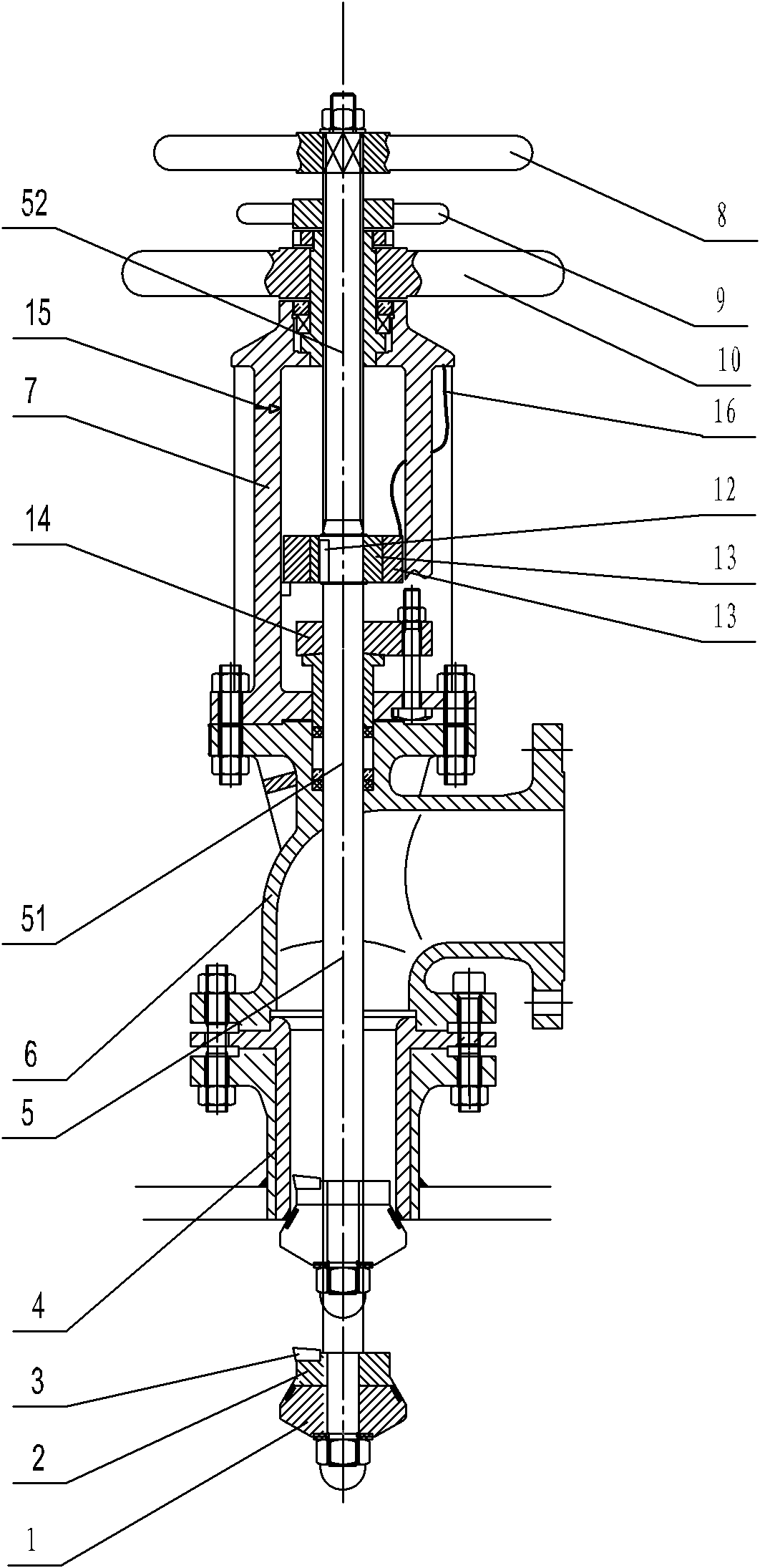

[0011] The pipe connection discharge valve capable of removing scars in the present invention includes a discharge valve and a cutting mechanism, and the discharge valve includes a valve body 6, a valve seat 4, a valve stem 5, a valve disc 1, a bracket 7, a lifting hand wheel 10 and a locking Nut 9, the upper part of the valve stem 5 is a screw rod 52, and the lower part is a polished rod 51; The connecting sleeve 12, the anti-falling fine chain 16 and the anti-rotation block 13, the cutting handle 8 arranged on the upper end of the screw rod 52 of the valve stem 5; the anti-rotation block 13 is movably arranged on the connecting sleeve 12, and the connecting sleeve 12 is firmly connected On the polished rod 51; the bracket is provided with a cutting mark 15, and when the valve disc 1 is in contact with the valve seat 4, the anti-rotation block is aligned with the cutting mark 15; the maximum cutting diameter of the cutter 3 is slightly smaller than the inner diameter of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com