Flashlight capable of focusing automatically

An automatic focusing and flashlight technology, applied in the field of flashlights, can solve problems such as unsatisfactory focusing effects and inability to realize automatic adjustment, and achieve ideal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

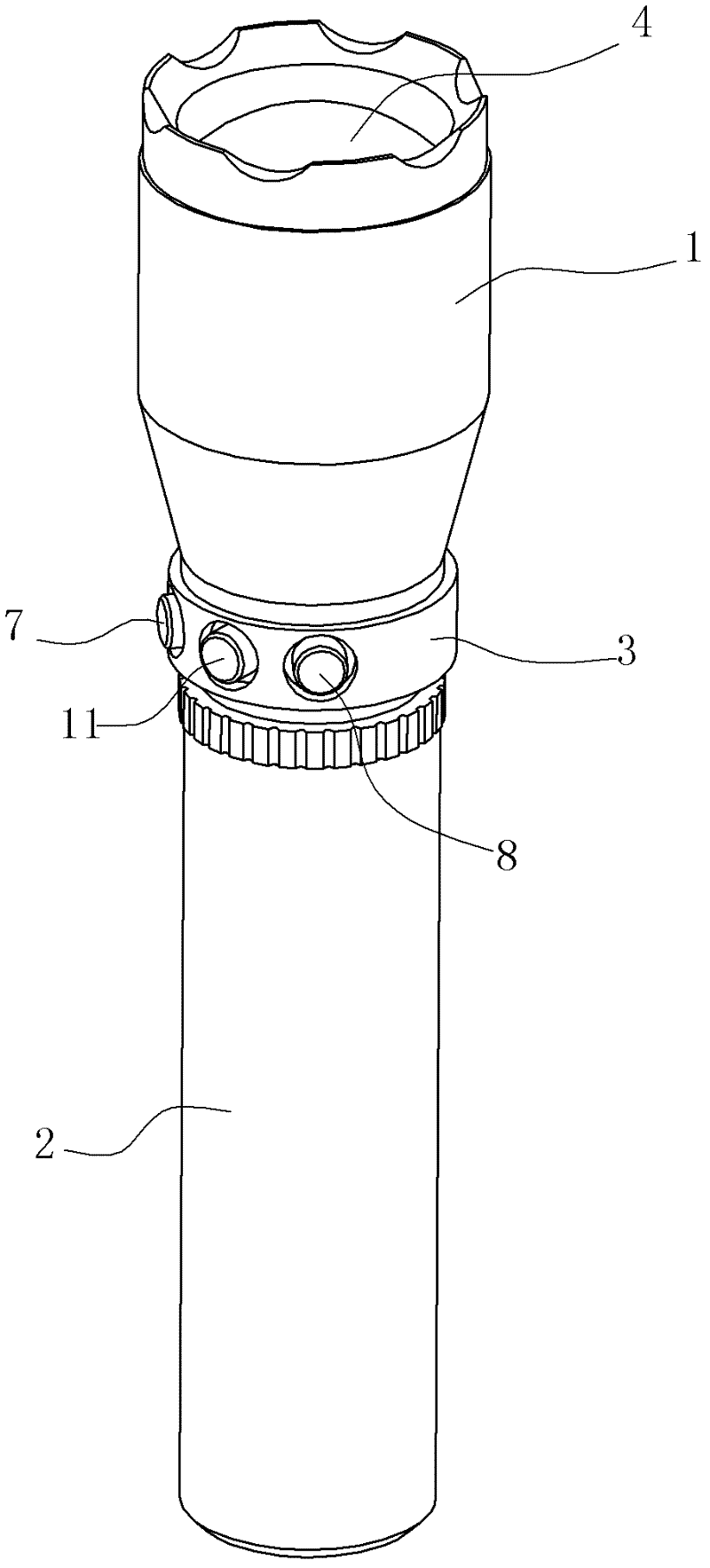

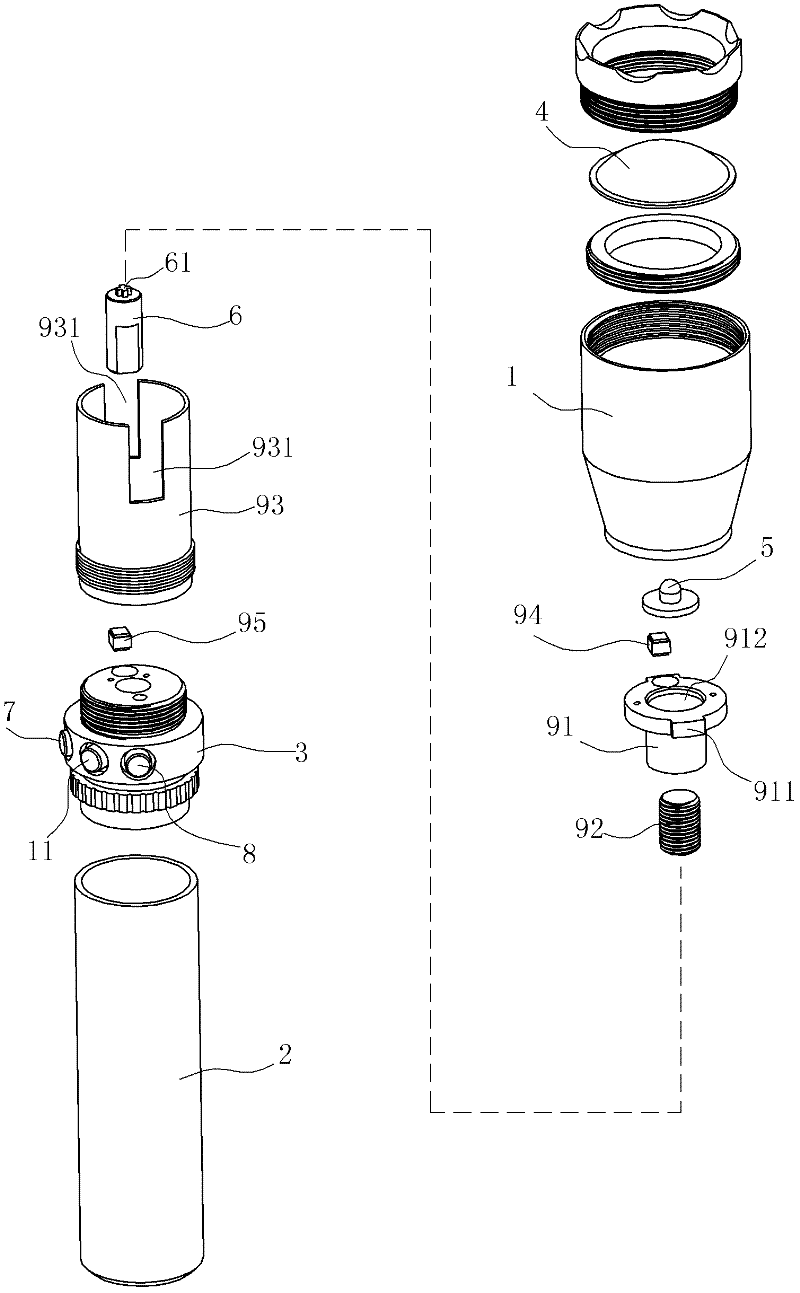

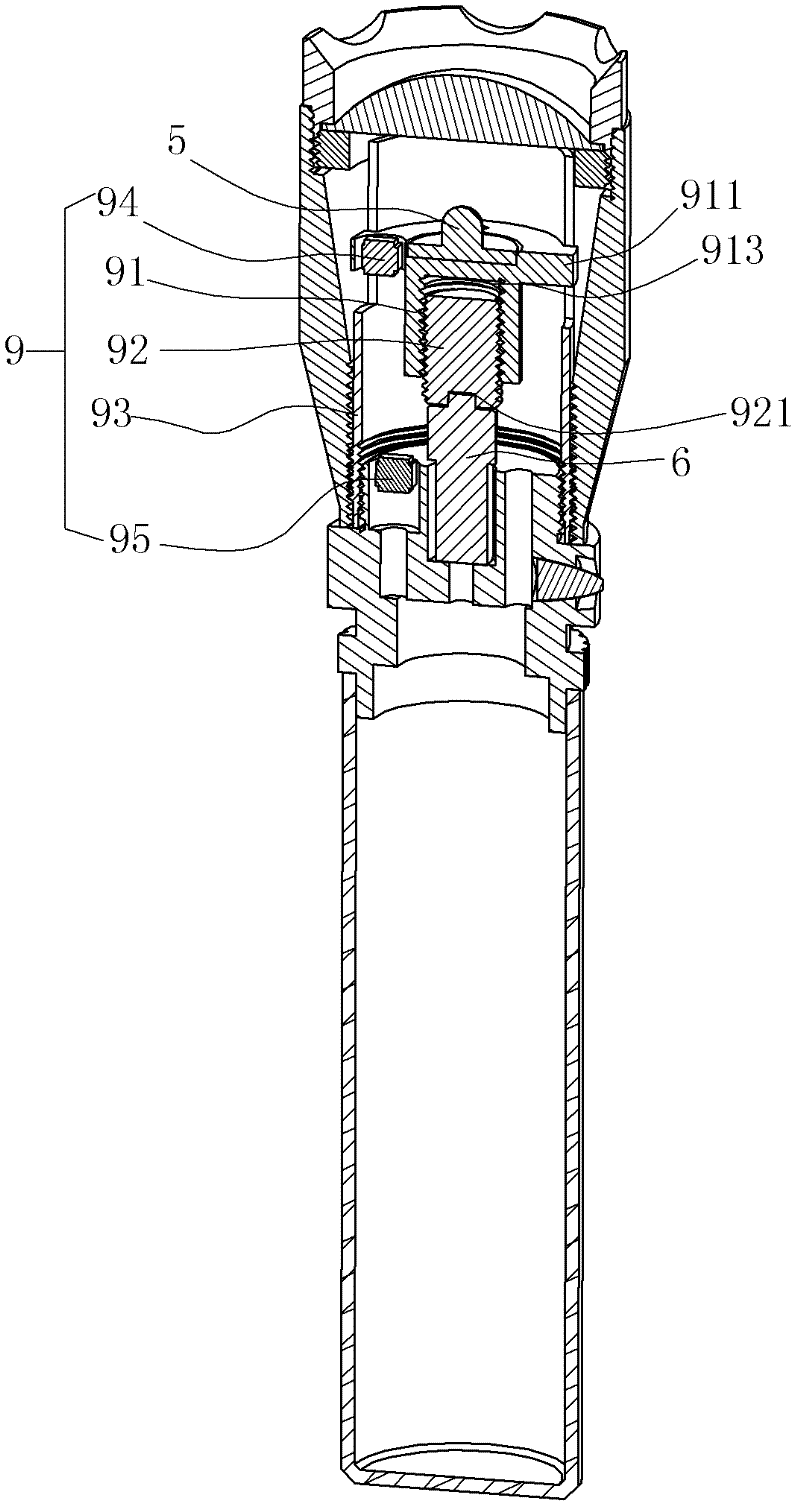

[0032] Such as Figure 1~4 The auto-focus flashlight shown includes a lamp cap 1 and a barrel body 2. A focusing lens 4 is arranged on the head of the lamp cap 1. A luminous body 5 is arranged inside the lamp cap 1. In addition, the interior of the lamp cap 1 also includes a lens for changing the focusing lens and a luminous body. The distance between the automatic distance adjustment mechanism, the automatic distance adjustment mechanism includes

[0033] A power mechanism 6 capable of forward and reverse rotation, which is a motor with a gearbox; a first button switch 7 for starting the forward rotation of the power mechanism; a second button for starting the reverse rotation of the power mechanism A switch 8; a focus adjustment assembly 9 connected to the output shaft of the power mechanism and capable of reciprocating displacement under the drive of the power mechanism, and the illuminant 5 is fixed on the focus adjustment assembly.

[0034] In this embodiment, the power ...

Embodiment 2

[0043] The difference from Embodiment 1 is that the inner wall of the lamp cap is directly provided with orbital grooves 12 distributed along the axial direction of the lamp cap; the focusing assembly 9 includes

[0044]The power mechanism seat 96 arranged inside the lamp cap, the edge of the head of the power mechanism seat 96 is provided with lugs that are clamped in the track groove 12 on the inner wall of the lamp cap, and the head of the power mechanism seat 96 is provided with a ring for fixing the The first groove 961 of the luminous body, the tail of the power mechanism seat is provided with a second groove 962, and the power mechanism 6 is arranged in the second groove 962;

[0045] Screw rod 92, the head of the screw rod 92 is connected with the output shaft of the power mechanism 6;

[0046] The screw rod seat 97 is connected with the lamp head 1 , and the screw rod seat 97 is provided with a thread groove 971 , and the screw rod 92 is screwed in the thread groove 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com