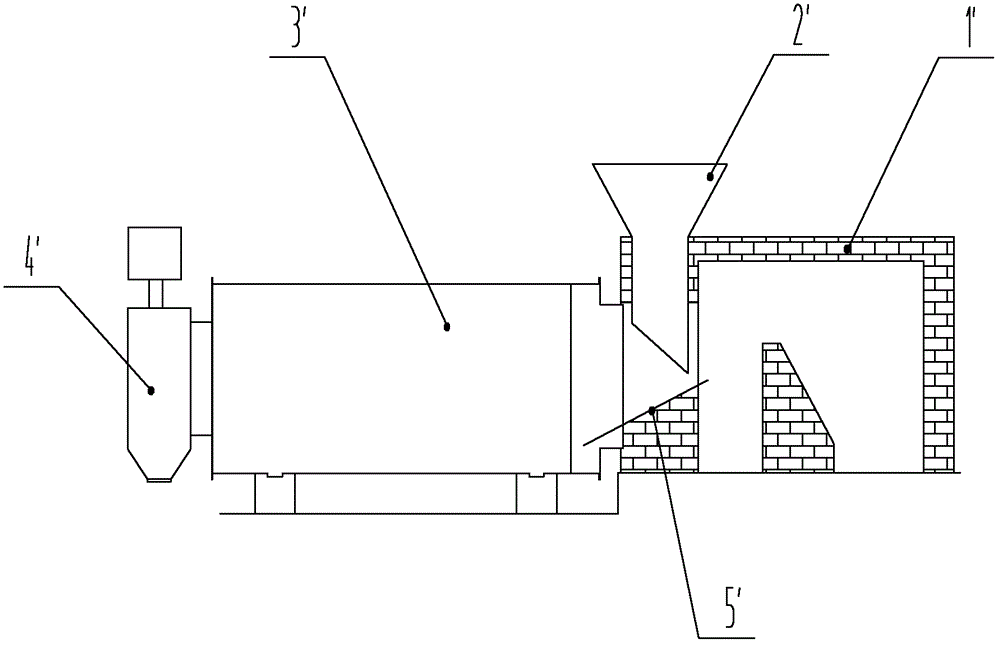

Wet sand drying system and dry-mixed mortar mixing station using same

A drying system, wet sand technology, applied in the direction of drying, drying solid materials, lighting and heating equipment, etc., can solve the problems such as the blockage of the sand inlet pipe, and achieve the effect of sufficient material scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

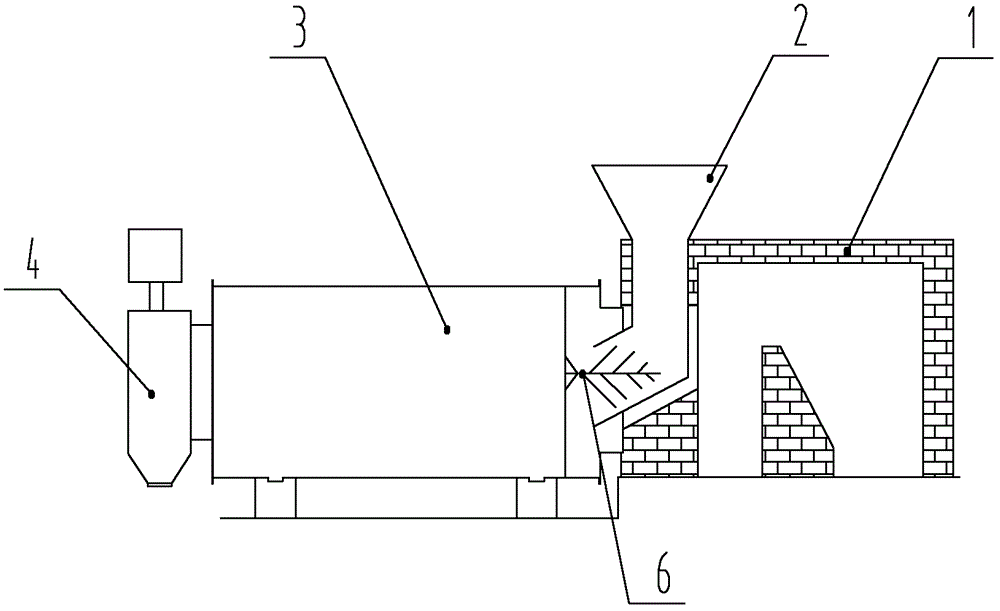

[0025] like figure 2 As shown, the wet sand drying system of the present invention includes a heating device 1, a sand inlet pipe 2, a dryer 3, a discharge port 4 and a scraping device 6, and the heating device 1 is preferably a hot blast stove, or a coal-fired furnace , gas furnace, oil furnace in any one.

[0026] In this embodiment, the dryer 3 can rotate, and the scraper device 6 is installed below the sand inlet pipe 2, and is fixedly connected with the inner wall of the dryer 3, and the wet sand is introduced into the dryer 3 through the sand inlet pipe 2 for supplying The heat device 1 provides enough heat energy for the dryer 3 to dry the sand, and the dried sand is discharged through the discharge port 4, and the scraping device 6 can rotate together with the dryer 3, so that the sand below the sand inlet pipe 2 The accumulated material is cleaned up.

[0027] In other embodiments, the dryer 3 may not rotate, but the scraping device 6 itself can move, and the accum...

Embodiment 2

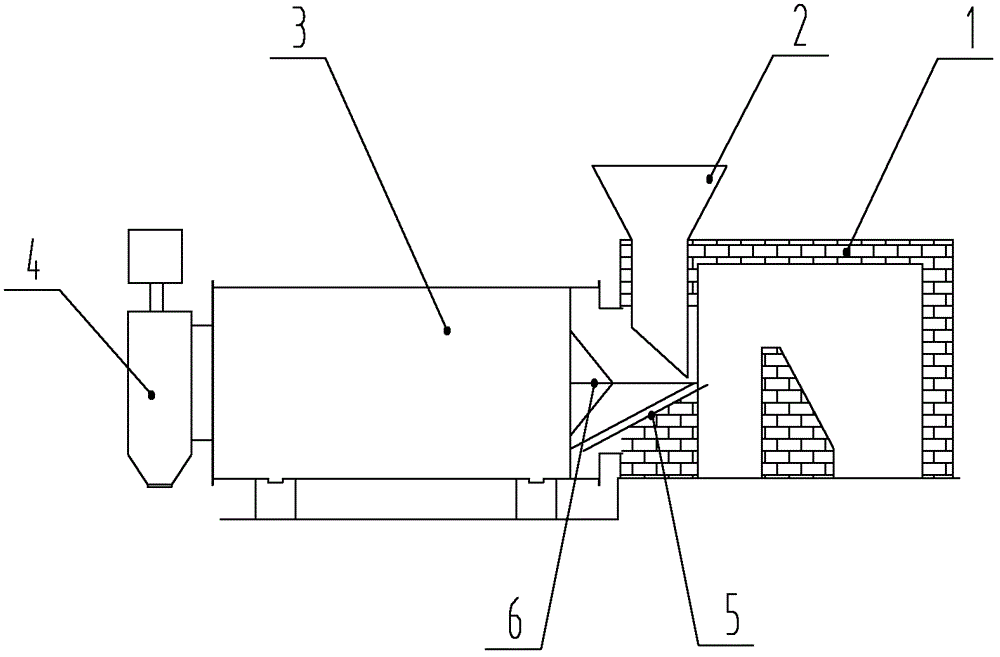

[0029] like image 3 As shown, the difference from Embodiment 1 is that a material guide plate 5 is provided below the discharge port of the sand inlet pipe 2, and the wet sand falls to the material guide plate 5 through the sand inlet pipe 2, and the material guide plate 5 guides the wet sand into the The dryer 3 and the scraping device 6 clean up the accumulated material above the material guide plate 5 to prevent the accumulation of wet sand below the sand inlet pipe 2 and cause blockage.

Embodiment 3

[0031] In this embodiment, the dryer 3 is rotatable, and the drying system may either include a material guide plate 5 or not.

[0032] like Figure 4 As shown, the scraping device 6 includes a support rod 61, a rotating shaft 63, and a scraping blade 64. One end of the supporting rod 61 is connected to the rotating shaft 63, and one end of the scraping blade 64 is arranged on the rotating shaft 63, and is far away from the supporting rod. 61. The symmetric center plane of the scraper blade 64 and the dryer 3 is set with a scraping angle of 45°. In other embodiments, the symmetry center plane of the scraper blade 64 and the dryer 3 can also be set to 0° , 15°, 30°, 60° any angle.

[0033] Preferably, there are three support rods 61, and the three support rods 61 are distributed at a certain angle, preferably 120°. The other end of the scraper blade 64 is connected to one of the support rods, and the other two support rods that are not connected to the scraper blade are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com