Weighing and removing machine

A rejecting mechanism and weighing technology, applied in the direction of weighing, detailed information of weighing equipment, weighing equipment of continuous material flow, etc., can solve the problems of inconvenient, quick and rapid change of varieties, affecting the products in the detection box, instability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

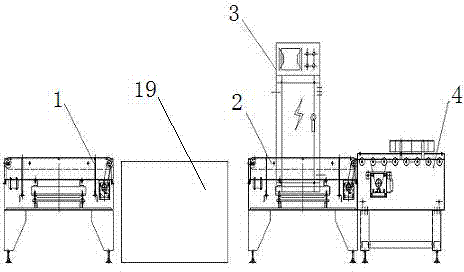

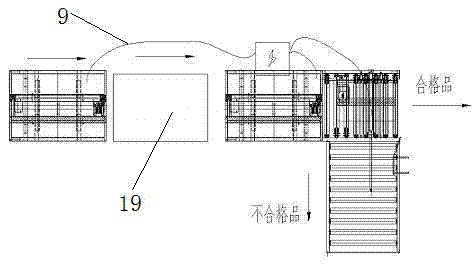

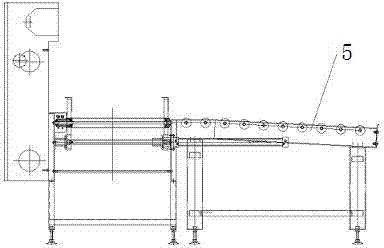

[0025] like Figure 1-Figure 13 As shown, the weighing and rejecting machine includes dynamic weighing mechanism 1, dynamic weighing mechanism 2, PLC control cabinet control system 3, rejecting mechanism 4, temporary storage mechanism 5, dynamic weighing machine, and PLC control cabinet control is installed on 2 System 3, through the data line, the weighing signal of the dynamic weighing mechanism 1 for weighing empty packages and the weighing signal of the dynamic weighing mechanism 2 after weighing the product are sent to the PLC control cabinet control system 3 respectively to calculate the weight of the product. Net weight, and the set upper and lower limits of product weight, those that meet the product requirements will pass through the rejecting mechanism 4 automatically, and those that do not meet the product requirements will be pushed to the temporary storage mechanism 5 by the rejected mechanism 4, and the alarm will be taken away manually, and dynamically weighed M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com