Microwave phase detection method for porosity of thermal barrier coating

A technology of thermal barrier coating and phase detection, which is applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem that the porosity of thermal barrier coating cannot be quickly, accurately, and pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

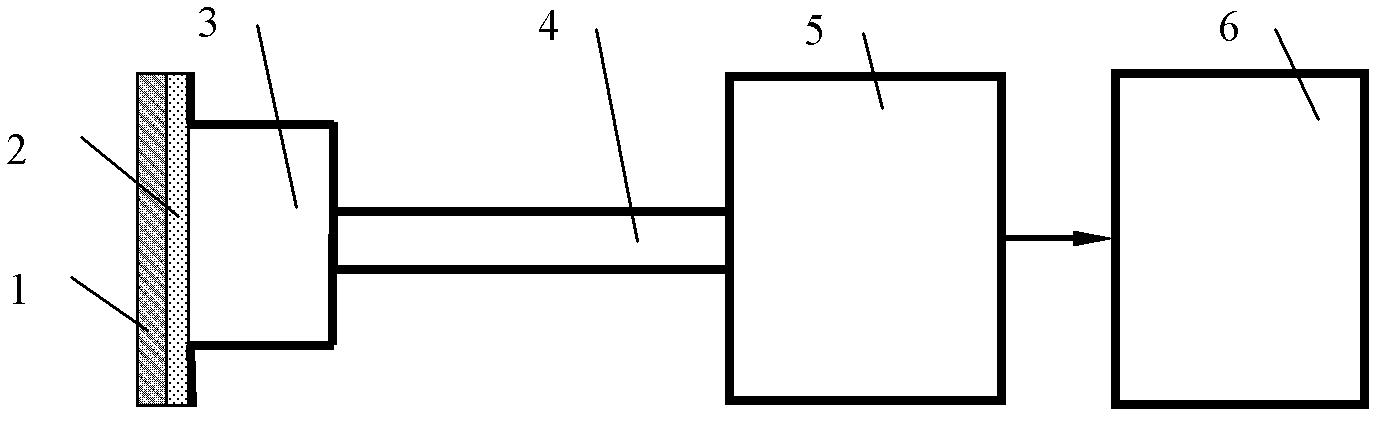

[0024] In conjunction with the content of the method of the present invention, the following examples of detecting the porosity of thermal barrier coatings by microwave phase method are provided, and the specific steps are as follows:

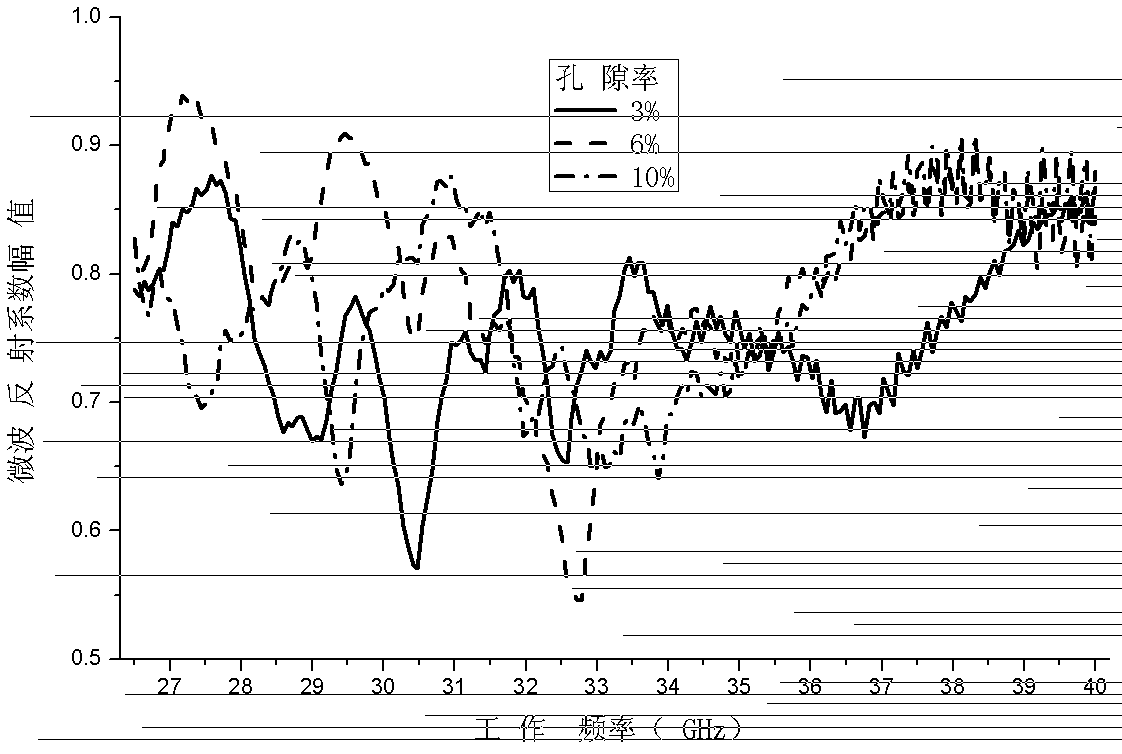

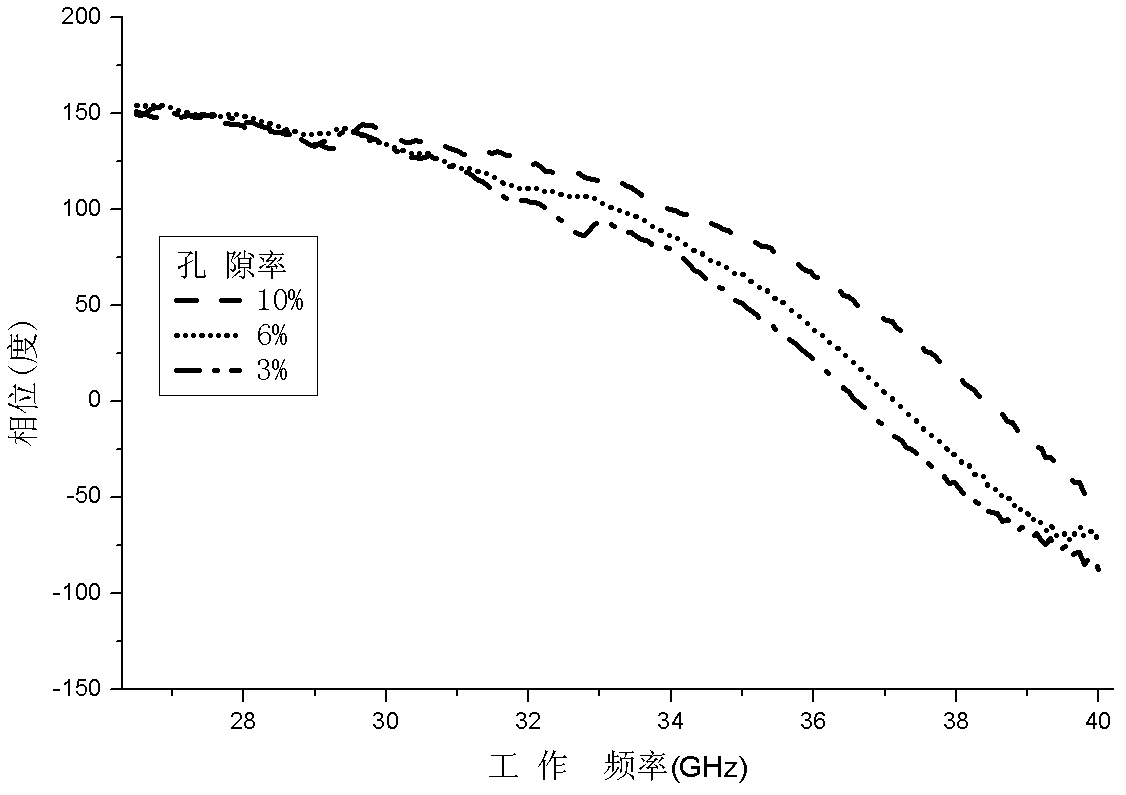

[0025] a. Use a microwave network analyzer to measure the reflection coefficient amplitude A and phase φ of the thermal barrier coating. The thickness of the measured thermal barrier coatings with different porosity is 400mm. figure 2 , image 3 Respectively, the relationship curves of microwave reflection coefficient amplitude, phase and operating frequency when detecting thermal barrier coatings with different porosities.

[0026] b. Calculation formula of reflection coefficient amplitude and the calculation formula of reflection coefficient phase φ = tan - 1 [ Im ( Γ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com