Trigger device and injection trigger method for chromatographic instrument inlet

A technology of triggering device and injection port, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of poor repeatability of retention time, unsuitable for portable instruments, easy failure of electronic devices, etc., achieving good applicability, reduction and exemption Manual operation steps or complex control system, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

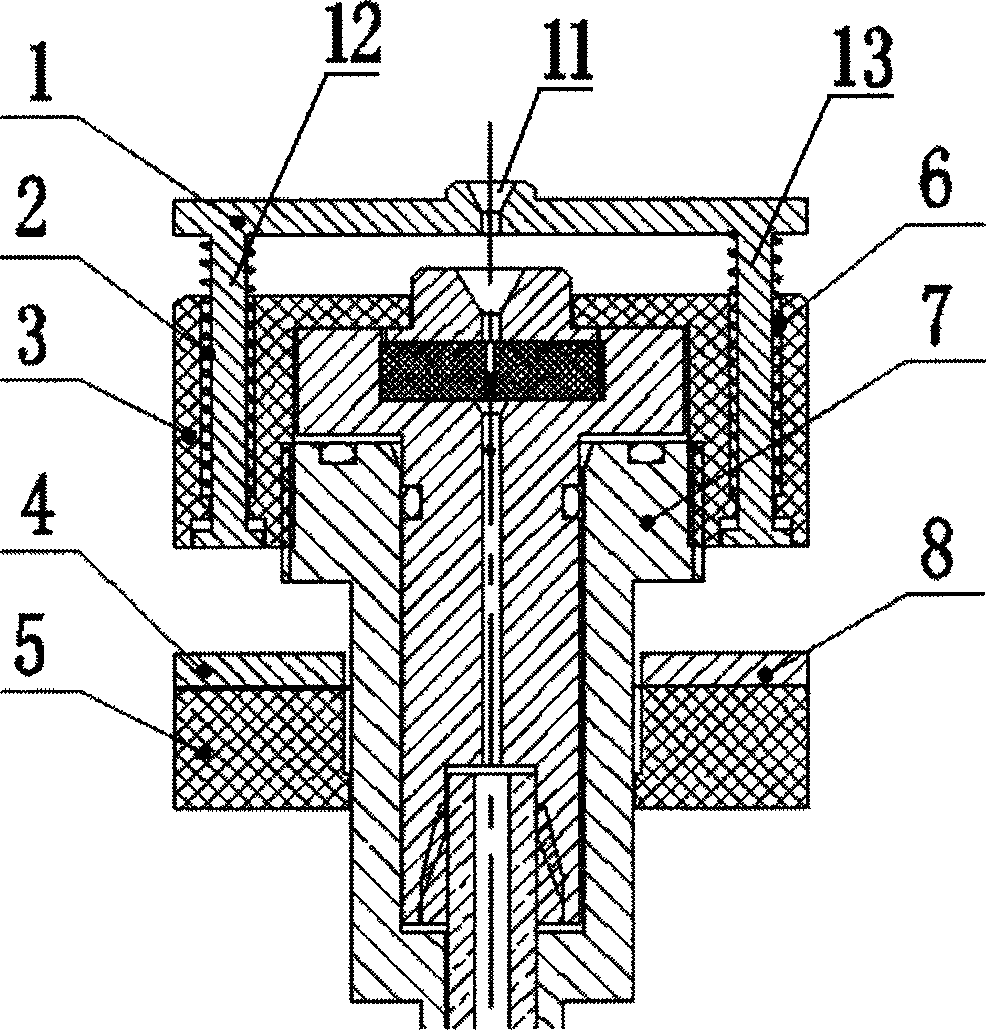

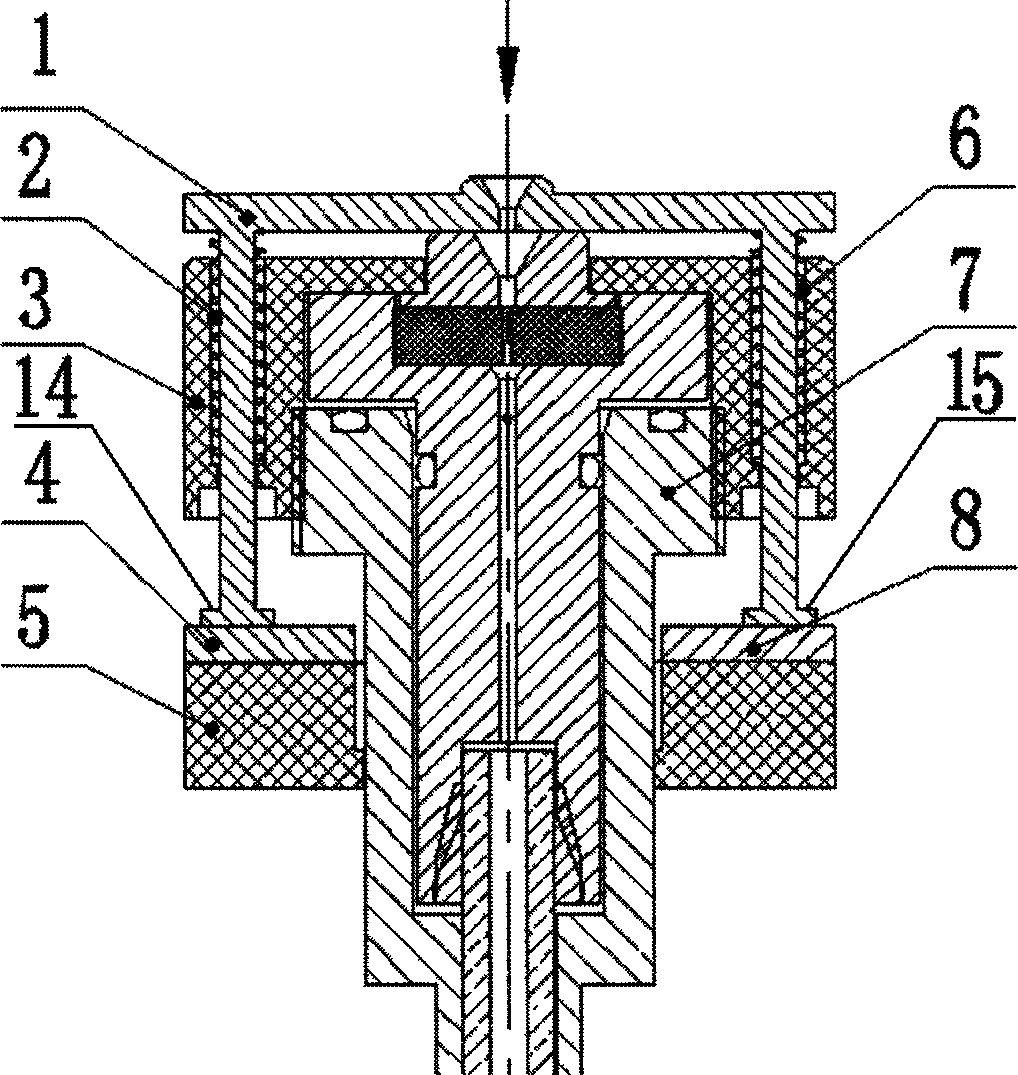

[0037] figure 1 , 2 The basic structural diagram of the triggering device of the chromatograph inlet of the embodiment of the present invention is schematically given, as figure 1 , 2 As shown, the trigger device includes:

[0038] Action piece 1, the action piece 1 has a through hole 11 through which the sampling needle passes. When the action piece 1 moves in the limit piece 3, the elastic pieces 2 and 6 are deformed, so that the first electrode 4 , The second electrodes 8 are electrically connected through the action piece 1, such as figure 2 As shown; the action piece 1 is made of conductive material, such as metal.

[0039] Preferably, the lower part of the action member has two rods 12 and 13 for connecting the first electrode and the second electrode, and the rods move within the limiting member 3 . Optionally, the end of the rod has circular trusses 14 , 15 , and the outer diameter of the circular trusses 14 , 15 is larger than the inner diameter of the limiting ...

Embodiment 2

[0052]An application example of the triggering device and the triggering method for the injection port of the chromatograph according to Embodiment 1 of the present invention in the detection of benzene series. In this application example, the upper part of the moving part is a disc, and the center of the disc has a through hole for the passage of the sampling needle, and the lower part has two semicircular rings. The elastic part adopts a spring, and the spring is located between the action part and the sample inlet, and an insulating seat is arranged at the bottom of the spring, and the insulating seat is arranged on the sample inlet. The moving part is made of copper, and the limit part is made of insulating plastic.

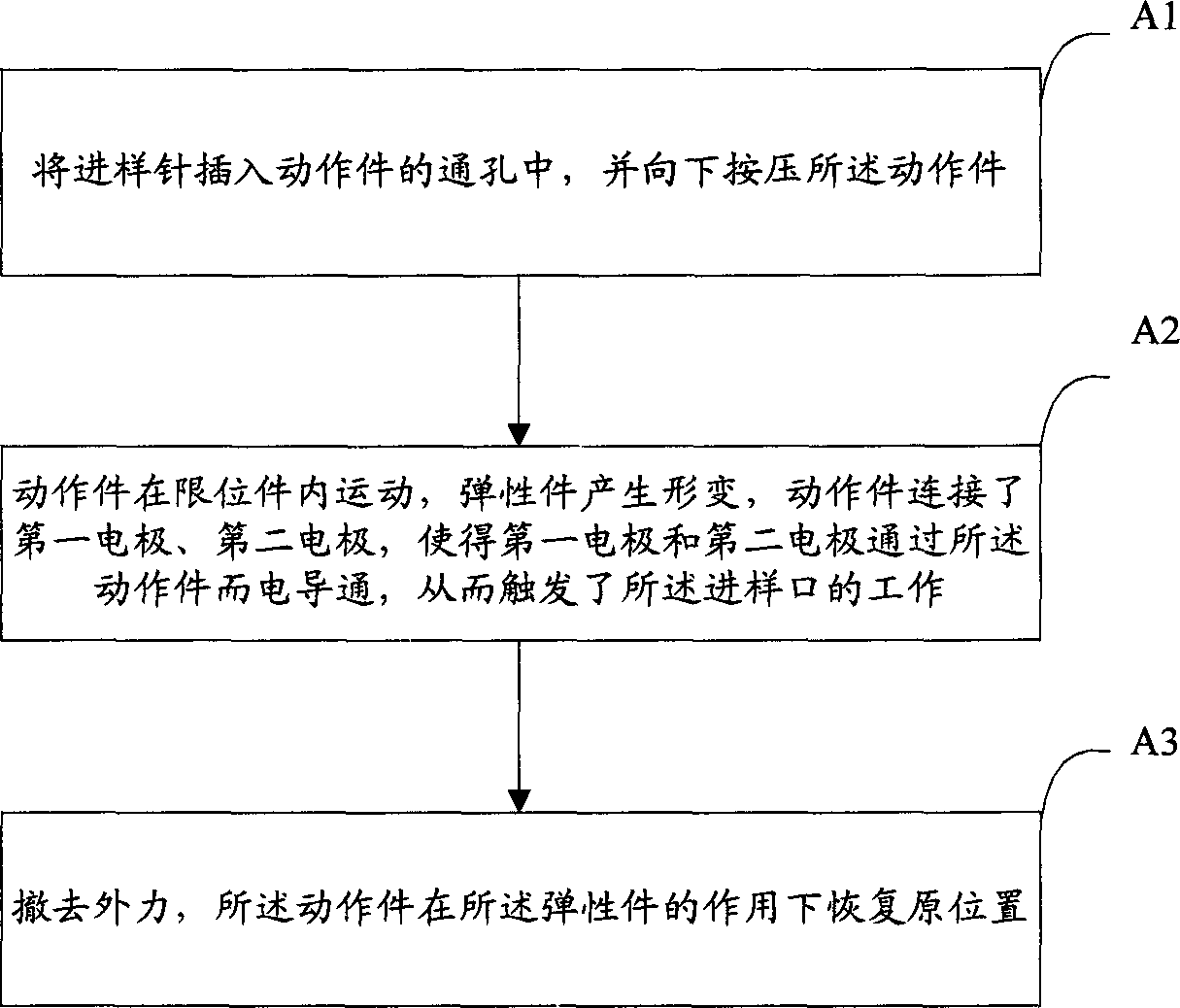

[0053] The operation mode of the above trigger (i.e. sample injection trigger method) is:

[0054] (A1) Insert the sampling needle into the through hole of the action piece, and press down the action piece by hand;

[0055] (A2) The two semi-circular rings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com