Composite light guide plate

A light guide plate and composite technology, applied in light guides, optics, optical components, etc., can solve the problems of low yield, high cost, and high difficulty, and achieve the effects of easy implementation, reduced process difficulty, and improved process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

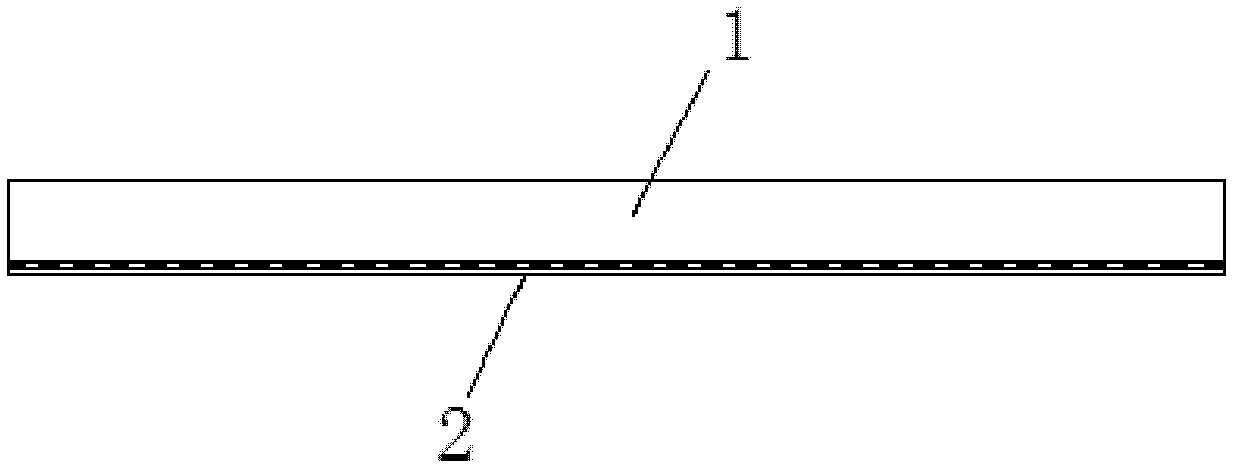

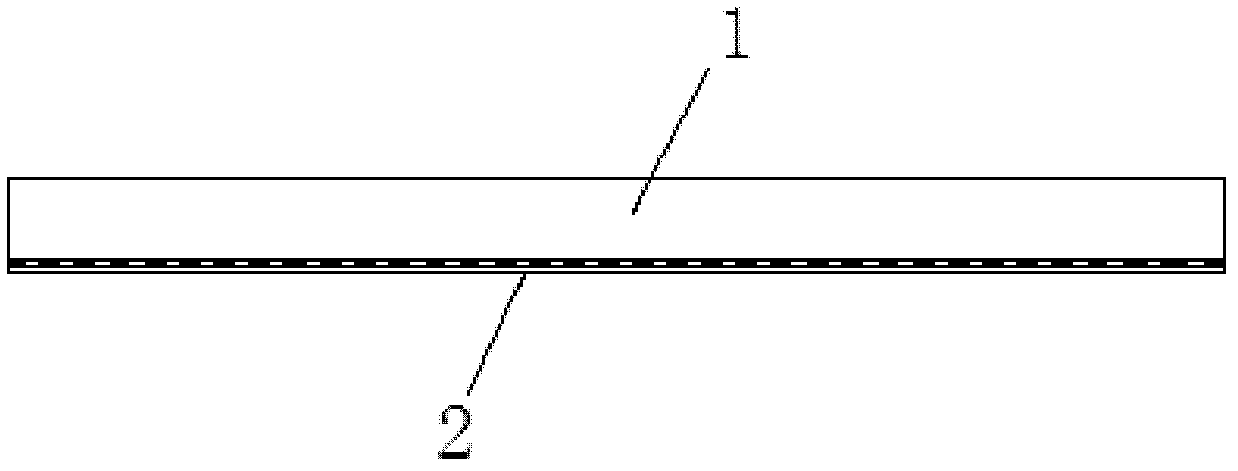

[0012] Embodiment: a composite light guide plate, with a transparent substrate 1 and a transparent film 2, the transparent film is printed with a number of light guide points, the transparent substrate has two opposite surfaces and are respectively the front and the back, the transparent A film is attached to the back of the transparent substrate. In the invention, the light guide points are first printed on the transparent film, and then the transparent film printed with the light guide points is combined with the transparent substrate to form a light guide plate. Since the light guide points are printed on the transparent film, it is better than the prior art It is easier to print directly on the transparent substrate, which reduces the difficulty of the process and improves the yield rate of the process. Even if there is a defective scrap, only the transparent film part needs to be scrapped, while the transparent substrate part is intact, so the cost can be reduced.

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com