Image pickup optical system

一种光学系统、光学面的技术,应用在光学、光学元件、仪器等方向,能够解决长间距、不利等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

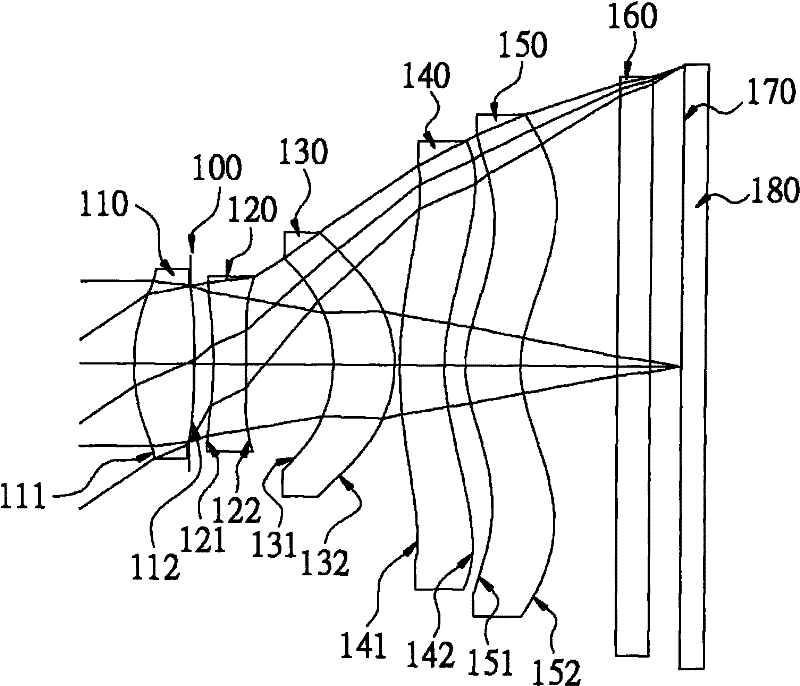

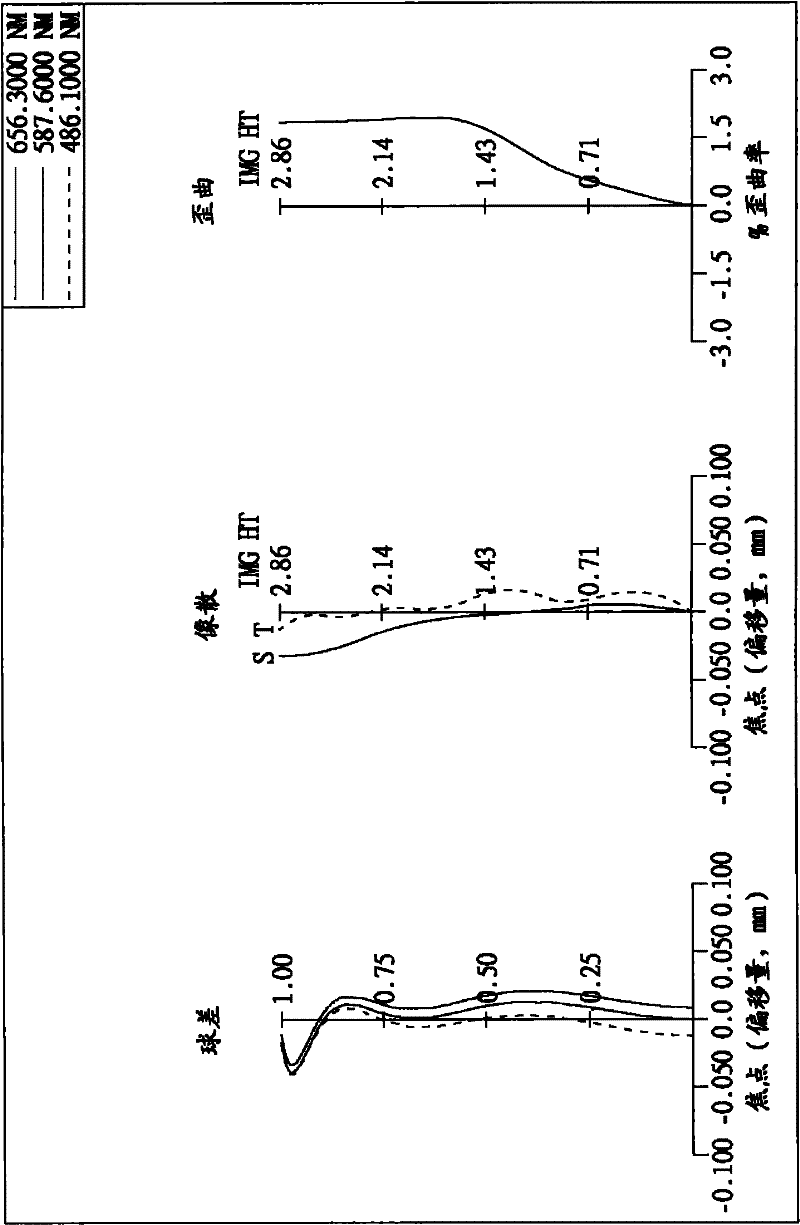

[0130] Please refer to the schematic diagram of the optical system of the first embodiment of the present invention Figure 1A , for the aberration curve of the first embodiment, please refer to Figure 1B . The imaging optical system of the first embodiment is mainly composed of five lenses, an infrared filter filter 160, an aperture 100, and an image sensor assembly 180; on the optical axis, from the object side to the image side in sequence Including: the first lens 110 with positive refractive power, the first lens 110 of this embodiment is a lens made of biconvex plastic material, and the object-side optical surface 111 of the first lens and the image-side optical surface 112 of the first lens are both Aspherical surface; the second lens 120 with negative refractive power is concave on the paraxial second lens object side 121, and the second lens image side 122 is a convex surface, which is a lens made of plastic material, and its second lens object side optical surface 1...

no. 2 example

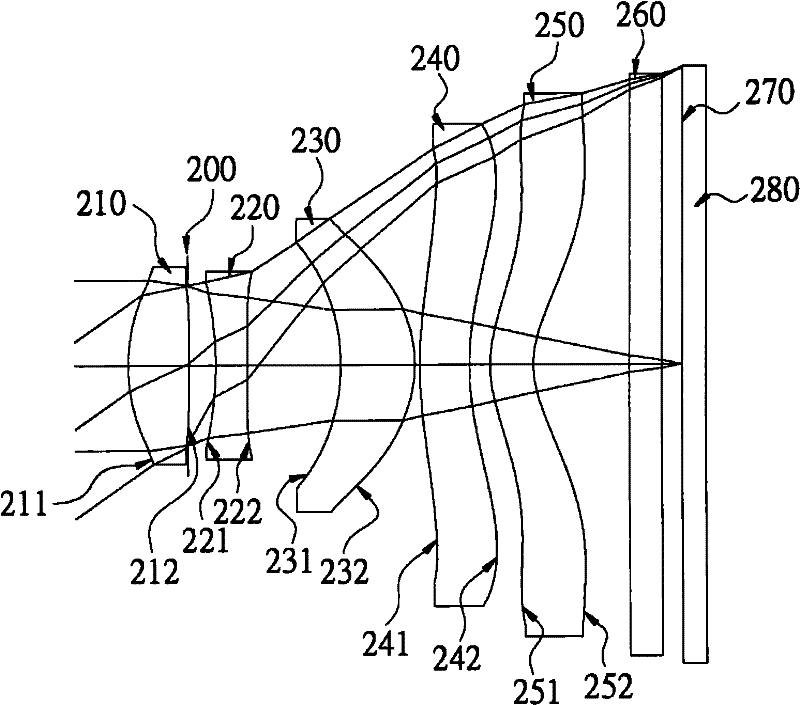

[0138] Please refer to the schematic diagram of the optical system of the second embodiment of the present invention Figure 2A , for the aberration curve of the second embodiment, please refer to Figure 2B . The imaging optical system of the second embodiment is mainly composed of five lenses, an infrared filter 260, an aperture 200, and an image sensor assembly 280; on the optical axis, from the object side to the image side in sequence Including: a first lens 210 with positive refractive power. In this embodiment, the first lens 210 is a lens made of biconvex plastic material, and the first lens object-side optical surface 211 and the first lens image-side optical surface 212 are both Aspherical surface; the second lens 220 with negative refractive power is concave on the paraxial second lens object side 221, and the second lens image side 222 is a convex surface, which is a lens made of plastic material, and its second lens object side optical surface 221 and the second...

no. 3 example

[0145] Please refer to the schematic diagram of the optical system of the third embodiment of the present invention Figure 3A , for the aberration curve of the third embodiment, please refer to Figure 3B . The imaging optical system of the third embodiment is mainly composed of five lenses, an infrared filter filter 360, a diaphragm 300, and an image sensor assembly 380; on the optical axis, from the object side to the image side, it includes: The first lens 310 of positive refractive power, in the present embodiment, the first lens 310 is a lens made of plastic material, the first lens object side optical surface 311 is a convex surface, and the first lens image side optical surface 312 is a concave surface at the paraxial place, The first lens object side optical surface 311 and the first lens image side optical surface 312 are both aspheric surfaces; the second lens 320 with negative refractive power, the second lens object side optical surface 321 is a concave surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com