Cooling device for vehicle

A technology for cooling devices and vehicles, applied in engine cooling, coolant flow control, failure prevention, etc., can solve problems such as control obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

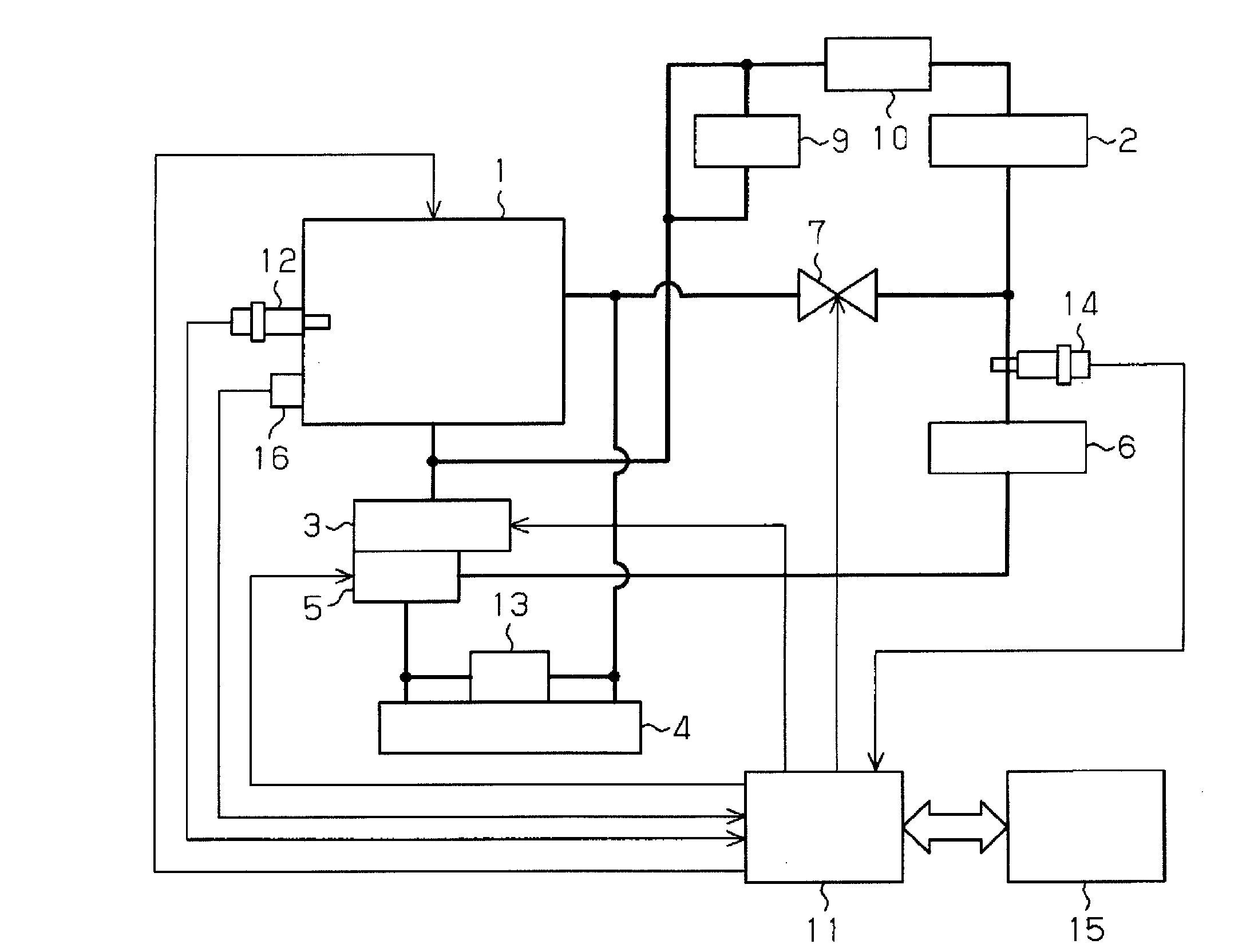

[0061] Below, according to Figure 1 to Figure 8 A first embodiment in which the present invention is embodied in a vehicle cooling device will be described.

[0062] figure 1 The structure of the cooling water circuit of the vehicle cooling device of this embodiment is shown. This cooling device includes a first cooling water circuit that circulates cooling water through the inside of the engine 1 , and a second cooling water circuit that circulates cooling water through the exhaust heat recovery device 2 without passing through the inside of the engine 1 . The cooling water in these cooling water circuits can be circulated individually by the same water pump 3 . The water pump 3 is an electric pump, and can change the flow rate of the cooling water to be discharged based on an external command. In addition, the exhaust heat recovery device 2 functions as a heat exchanger for exchanging heat between the exhaust gas of the engine 1 and the cooling water of the second cooli...

no. 2 approach

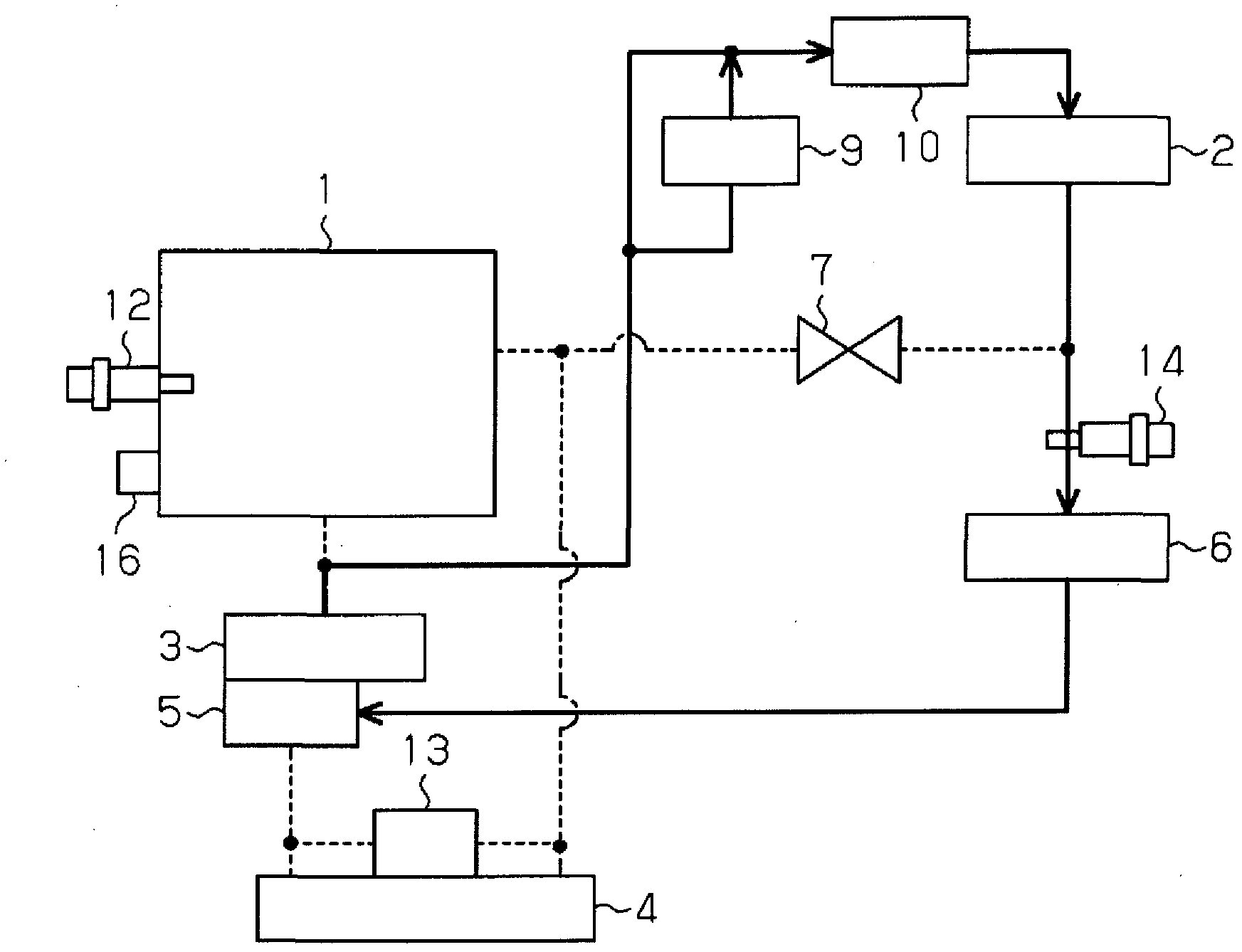

[0097] Next, based on Figure 9 to Figure 16 A second embodiment of the present invention will be described.

[0098] In this embodiment, when the failure of the valve to open occurs in the valve 7, in order to suppress the overheating of the engine 1, the circulation of the cooling water in the bypass path of the first cooling water circuit is carried out instead of forcing The thermostat 5 is opened to circulate the cooling water through the main path of the first cooling water circuit.

[0099] Specifically, in the vehicle cooling device of this embodiment, the following structure is adopted: even if the valve 7 fails to open, by making the discharge flow rate of the water pump 3 more than the normal use range, the cooling water is cooled in the first cooling stage. Circulation in a bypass path in a water circuit. As such a configuration, it is conceivable to specifically make the valve 7 into Figure 9 The composition of the representation. The structure of the valve 7...

no. 3 approach

[0108] Next, based on Figure 17 A third embodiment of the present invention will be described. This embodiment is an example for coping with a failure such as disconnection of one of the water temperature sensors 12 and 14 in the first embodiment.

[0109] When one of the water temperature sensors 12 and 14 fails, the temperature of the cooling water detected by the failed water temperature sensor becomes a value different from the actual value. various controls. For example, when the water temperature sensor 12 fails, various controls of the engine 1 cannot be properly performed based on the cooling water temperature thw1, and when the water temperature sensor 14 fails, the air in the heater core 6 cannot be appropriately controlled based on the cooling water temperature thw2. Heating control and control of blowing the heated air into the vehicle interior.

[0110] Therefore, in the vehicle cooling device of the present embodiment, when one of the water temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com