Electric machine, hydraulics unit

A technology of rotor shaft and centrifugal disc, which is applied in the field of hydraulic units of motor vehicles, can solve problems such as damage functions, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

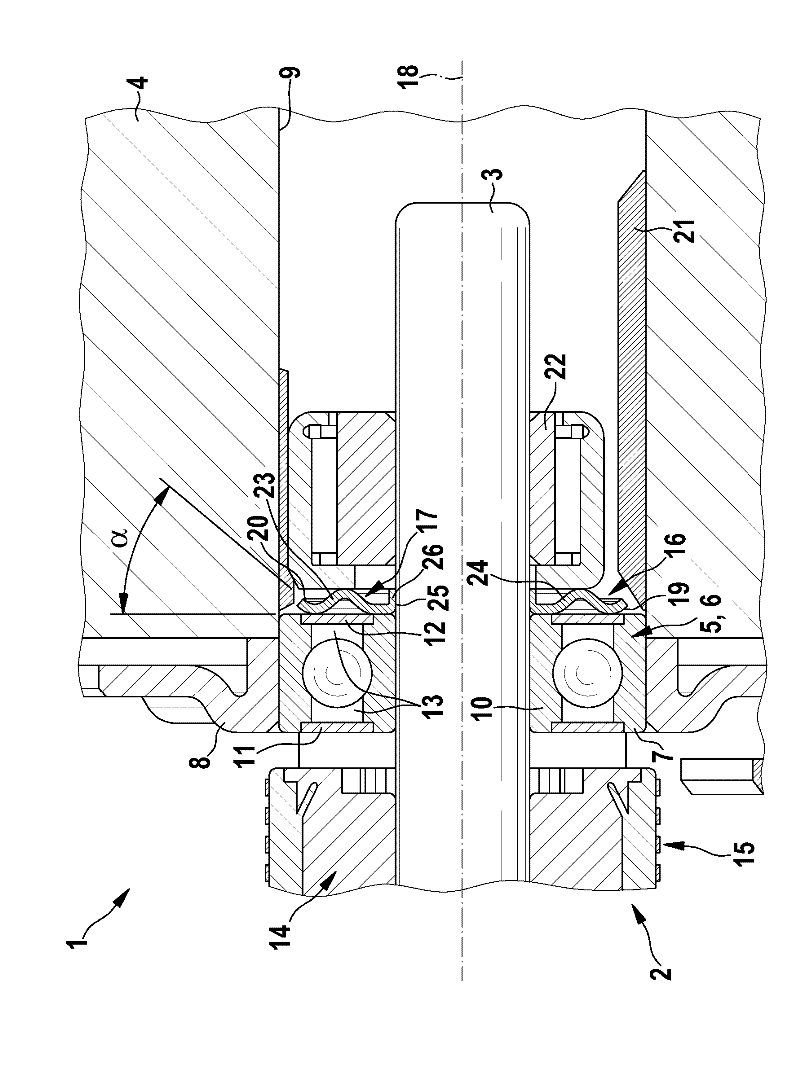

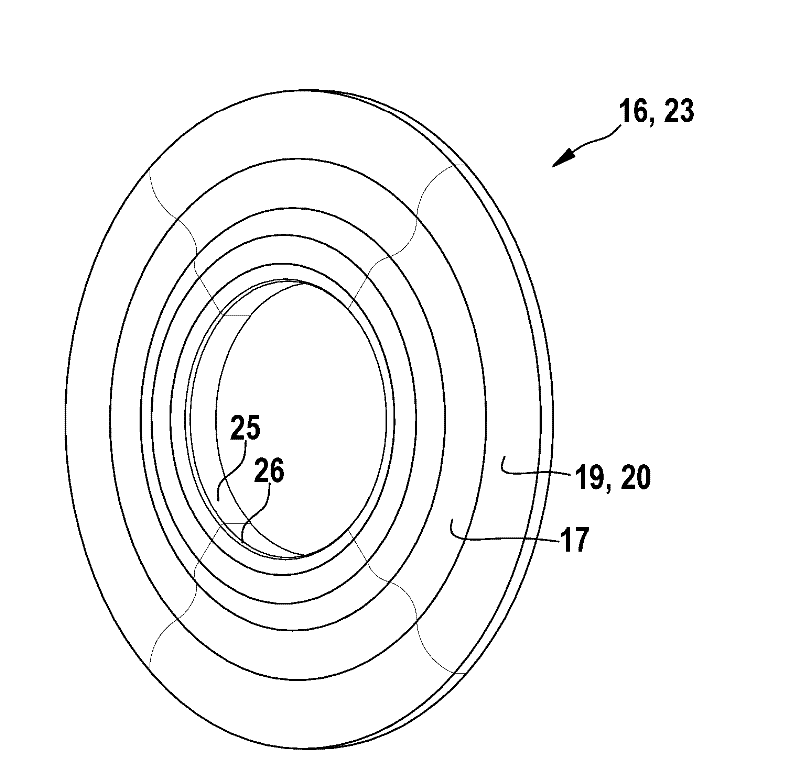

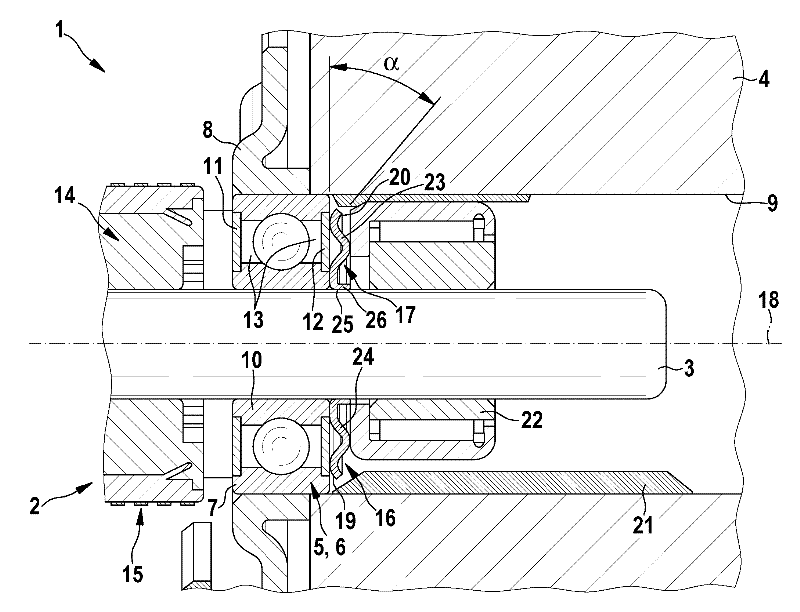

[0017] figure 1 A simplified sectional illustration of a section of hydraulic unit 1 is shown. The hydraulic unit 1 includes an electric motor 2 whose rotor shaft 3 is mounted in a housing 4 . The housing 4 is therefore a component not only of the hydraulic unit 1 but also of the electric machine 2 . A rolling element bearing 5 is provided for supporting the rotor shaft 3 , which is presently designed as a ball bearing 6 . The rolling element bearing 5 is substantially held radially on its outer ring 7 by a bearing cover 8 and protrudes partially into a receptacle 9 of the housing 4 . The rolling element bearing 5 also has an inner ring 10 which is arranged in a rotationally fixed manner on the rotor shaft 3 . The rolling bodies in the form of balls are guided between the outer ring 7 and the inner ring 10 into corresponding grooves. The rolling element bearing 5 is sealed on its axial end faces by means of sealing rings 11 , 12 , wherein the sealing rings 11 , 12 are fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com