Automatic high-efficiency bottle washing machine

A bottle washing machine, high-efficiency technology, applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of no uniform standard for manual cleaning, difficulty in the cleanliness of utensils, and potential safety hazards, etc., to achieve The effect of shortening the working cycle, ensuring the cleanliness of washing, and reducing the labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

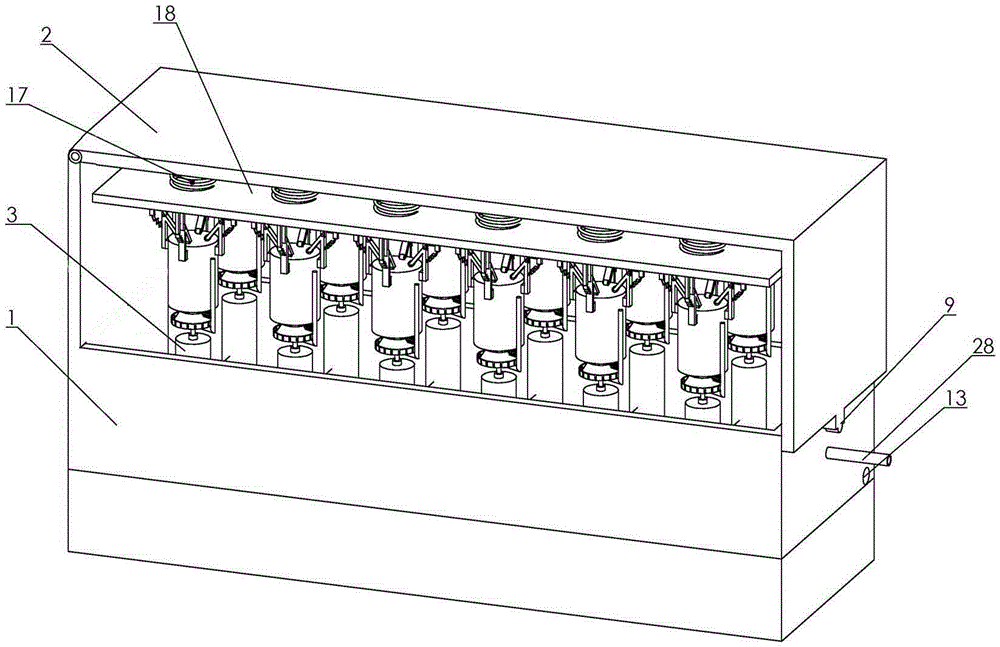

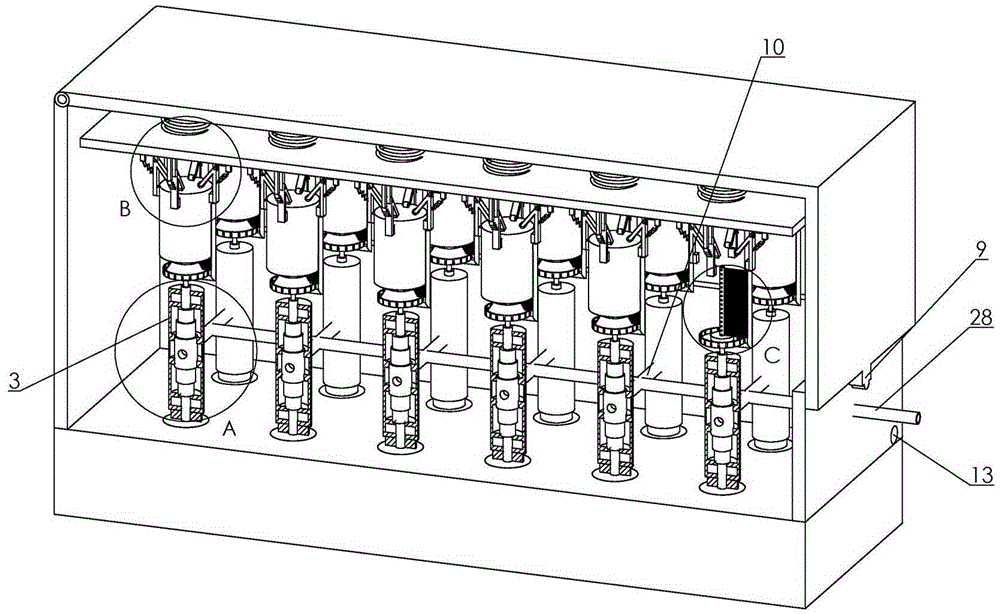

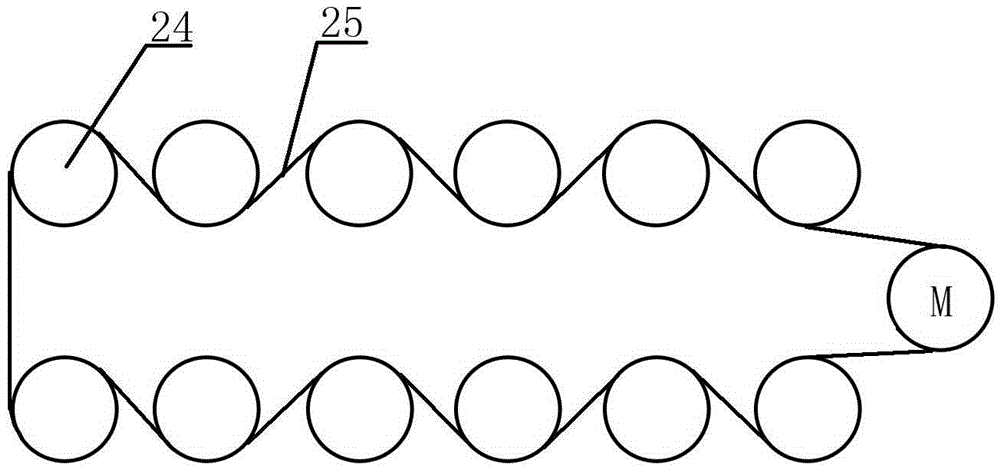

[0024] as attached Figure 1-5As shown, the present invention is composed of a cleaning device, a pressing device, a transmission device, and a waterway control device. The cleaning device includes a cleaning tank 1, a cover plate 2, a still water tank 3, bearing blocks 4 arranged at the upper and lower ends of the still water tank 3, The bearing 5 set in the bearing seat 4, the transmission connection shaft 30 set in the still water tank 3 and inserted in the bearing hole of the bearing 5, the inner brush 7 and the outer brush 8, and the inner brush 7 and the outer brush 8 bottle holders 6 between the ends; one end of the cover plate 2 is hinged with the side wall of the cleaning tank 1, and the other end is connected with the side wall of the cleaning tank 1 through a lock 9, and the side wall of the cleaning tank 1 is hinged. The bottom is provided with an overflow port 13, and the still water tanks 3 are connected through the communication pipe 10 and connected with the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com