Movable support mechanism for ultra-long screw

A support mechanism, mobile technology, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc., to achieve high-speed normal operation, increased service life, and good accuracy retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

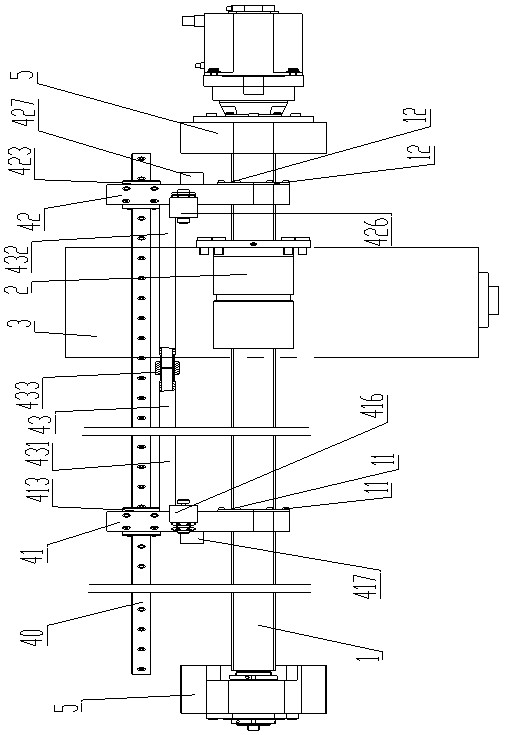

[0050] Such as figure 1 As shown, an ultra-long lead screw mobile support mechanism of the present invention includes a drive device, a lead screw 1, a screw nut 2 and a sliding seat 3, the two ends of the lead screw 1 are fixed by a lead screw support 5, and the drive device and the lead screw 1 connects and drives the lead screw 1 to rotate, the screw nut 2 meshes with the lead screw 1 to form a screw pair, and the slide seat 3 is connected to the screw nut 2, which also includes a support frame that slides relative to the lead screw 1 to support The frame supports the lead screw 1, and the support frame slides with the sliding seat 3.

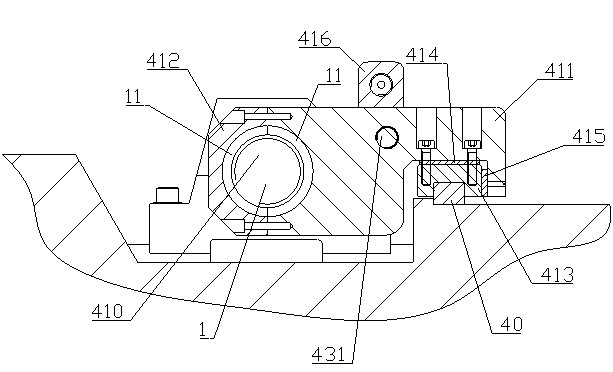

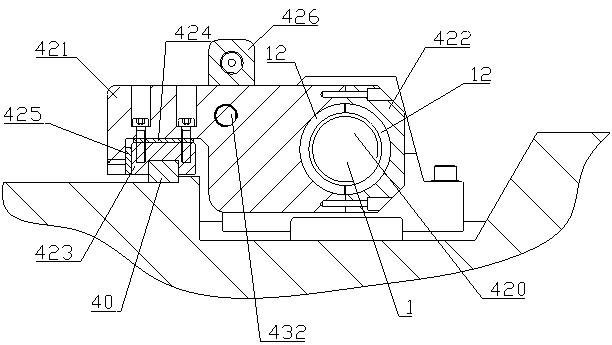

[0051]The support frame is mainly formed by a linear rail 40, a first support 41, a second support 42 and a connecting rod 43; the first support 41 is set be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com