Rear drive assembly of mechanical intelligent self-adaptive automatic gearbox

An automatic transmission and self-adaptive technology, applied in mechanical equipment, clutches, one-way clutches, etc., can solve problems such as reducing volume, and achieve the effects of improving power performance, extending running time, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

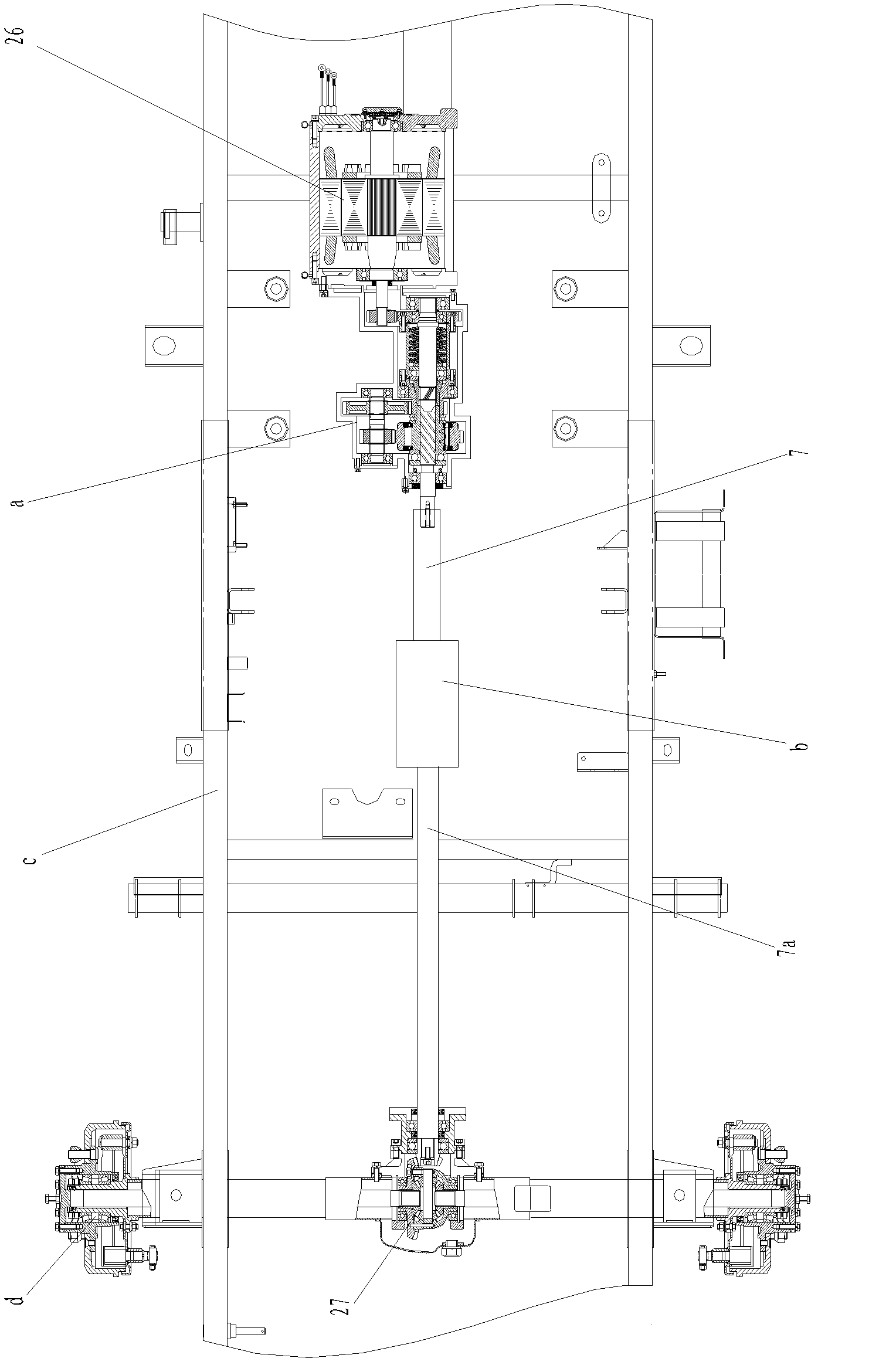

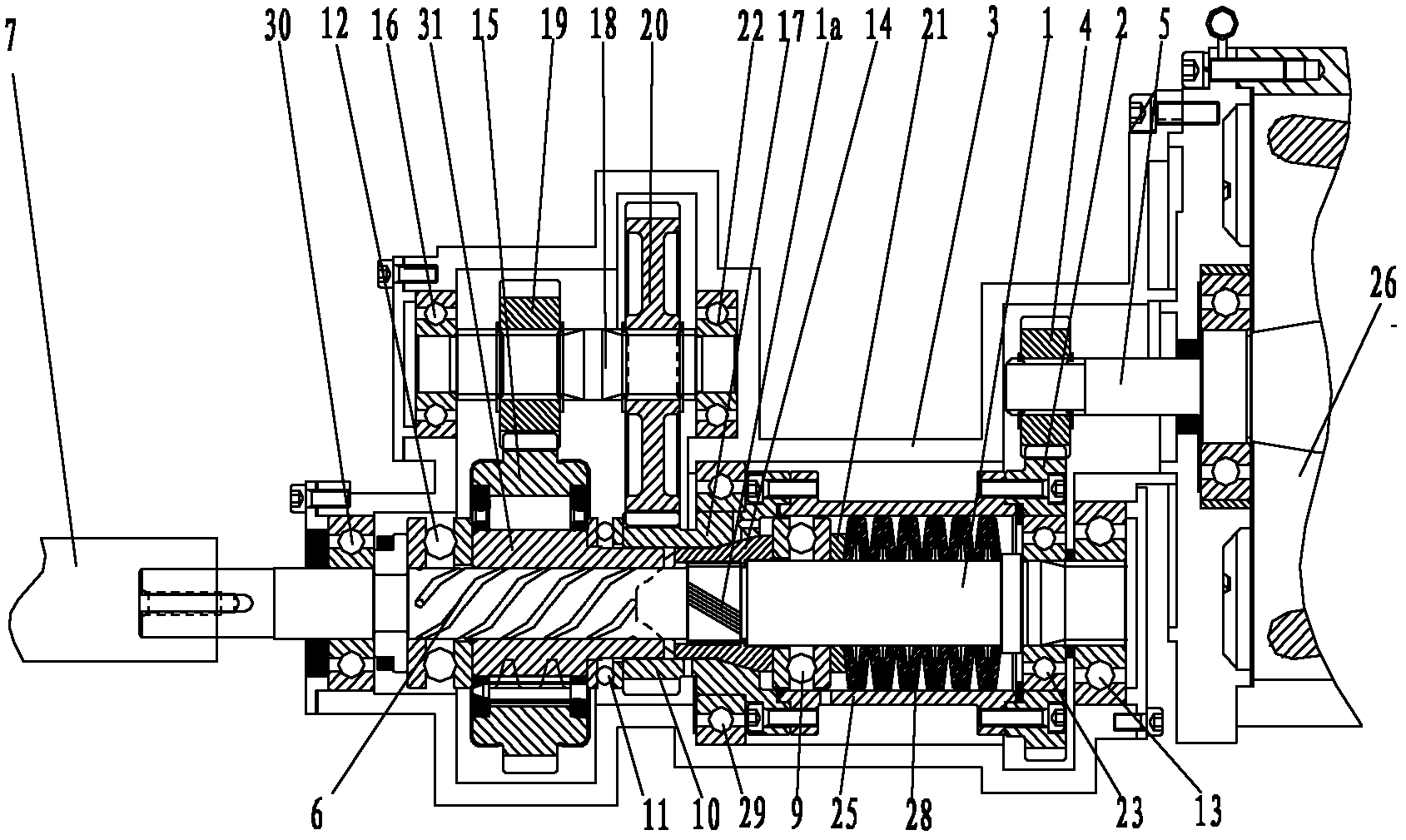

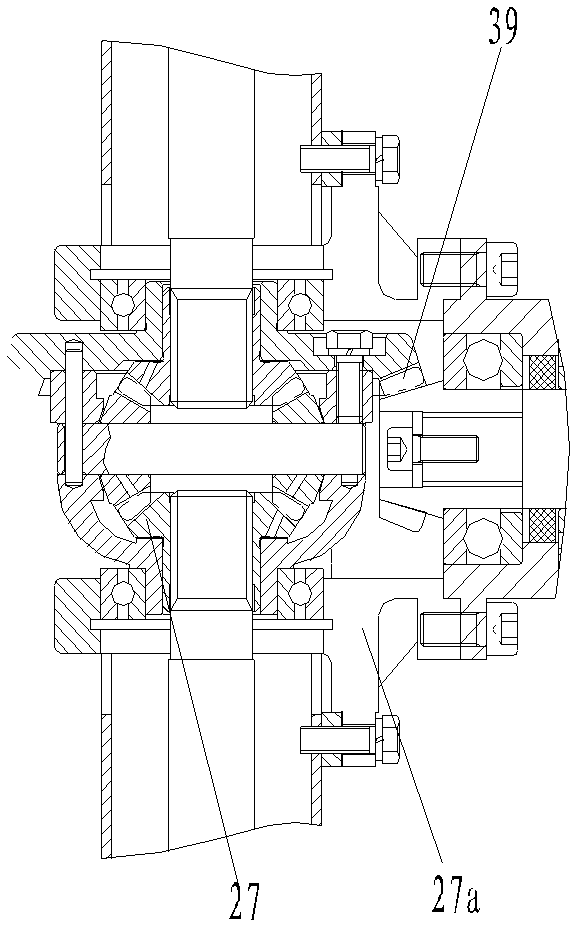

[0036] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 A schematic diagram of the axial cross-sectional structure of the transmission, image 3 is the schematic diagram of the axial cross-sectional structure of the differential, Figure 4 It is a schematic diagram of the structure of the axial outer taper sleeve of the torus, Figure 5It is a structural schematic diagram of the inner ring of the overrunning clutch, Figure 6 Schematic diagram of the structure of the overrunning clutch, Figure 7 It is a schematic diagram of the support column, the support piece and the reed, Figure 8 It is a schematic diagram of the reed structure, Figure 9 It is a schematic structural diagram of an axial partial section of an overrunning clutch, as shown in the figure: the power device of this embodiment is a motor, which rotates clockwise when viewed from the back to the front during work.

[0037] The rear drive assembly of the mechanical inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com