Dyeing device for tan-sheep skins

A dyeing device and technology for sheepskin, applied in the fields of dyeing method, small hide/big hide/leather/fur treatment, leather/skin/leather/rawhide chemical treatment equipment, etc. Large scale, sewage pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

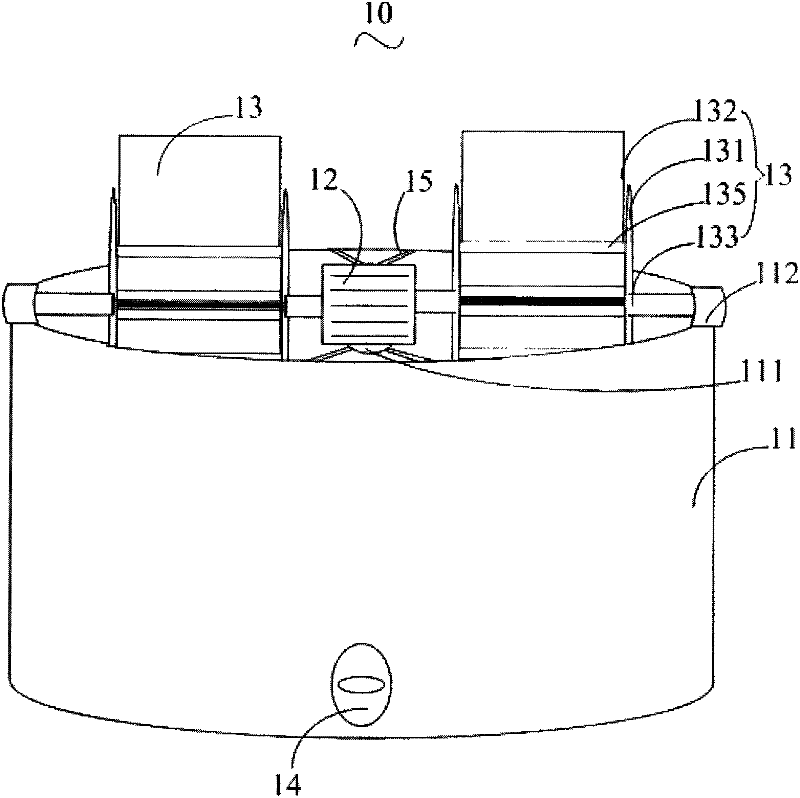

[0009] Please also see figure 1 , The sheepskin dyeing device 10 includes a dye solution storage tank 11 , a DC motor 12 , and a mixing module 13 with two blades.

[0010] The center of the dye solution storage barrel is provided with a support column 111, and the height of the support column 111 is the same as that of the dye solution storage barrel 11. Two positioning pieces 112 are arranged on the mouth of the dye solution storage bucket 11, and the two positioning pieces 112 are facing each other. .

[0011] The DC motor 12 is placed on the top of the support column 111, and the two blade stirring modules 13 are correspondingly arranged on both sides of the DC motor 12, and each blade stirring module 13 is located between the DC motor 12 and the corresponding positioning member 112. One end of each blade stirring module 13 is rotatably fixed to the corresponding positioning member 112 , and the other end of the blade stirring module 13 is connected to the rotating shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com