Spring steel material with high strength and high hardenability

A high hardenability, spring steel technology, applied in the field of leaf springs, high strength and high hardenability spring steel materials, can solve the problem of high quenching cracking tendency, yield strength can not meet high stress, lightweight design requirements, etc. problem, to achieve the effect of low quenching cracking tendency and high hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] 1. Embodiment:

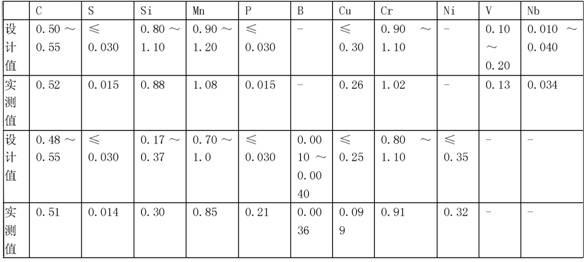

[0009] 1, a kind of spring steel material of high strength toughness and high hardenability of the present invention, composition is set according to following proportioning, by weight percentage, its composition is: the C of 0.50%~0.55%, the Mn of 0.90%~1.20%, 0.80%~1.10% Si, 0.10%~0.20% V, 0.90%~1.10% Cr, 0.010%~0.040% Nb, ≤0.03% P, ≤0.03% S, and the rest is Fe;

[0010] 2, adopt the process production of mature conventional production leaf spring, such as the hot rolling process method of producing 52CrMnBA spring steel plate, can realize the production of the present invention.

[0011] 2. Comparison of various indicators:

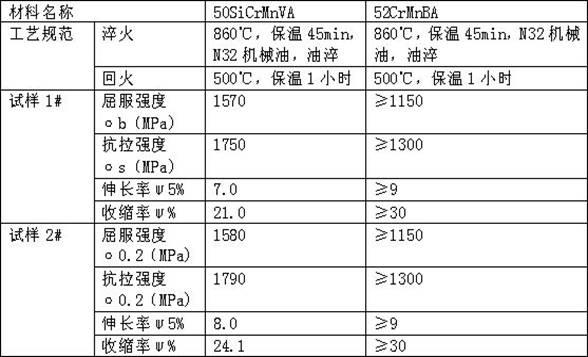

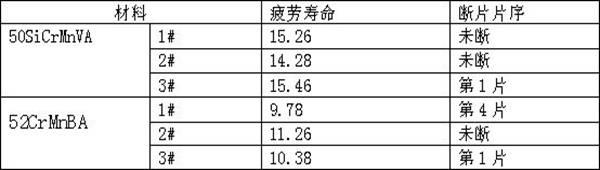

[0012] The applicant of the present invention entrusts the manufacturer to hot-roll this material of a certain specification, and has carried out related tests. For convenience of comparison, 52CrMnBA with better comprehensive mechanical properties under this specification is selected for comparison. Tests have shown that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com