Pushing-needle type anti-theft nut

An anti-theft nut and pin technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of unstable anti-theft effect and high clearance tolerance requirements, achieve reliable anti-theft function, improve anti-disassembly torque, and eliminate tolerance gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

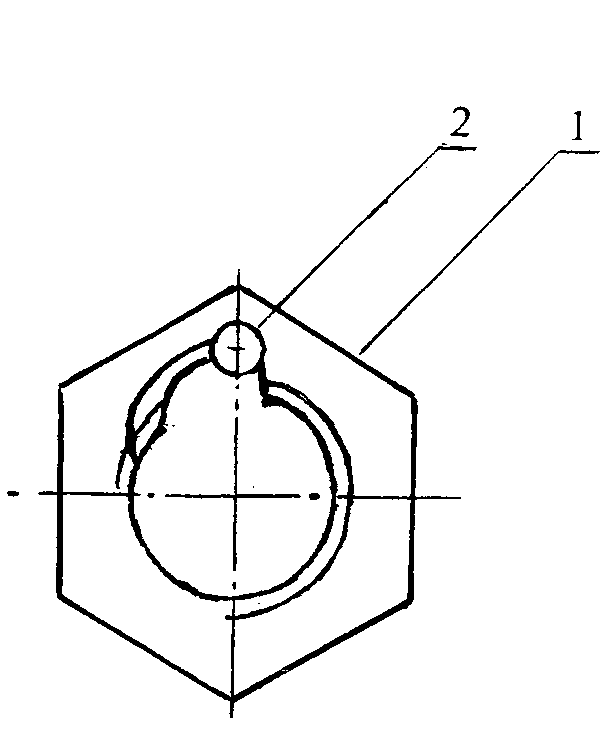

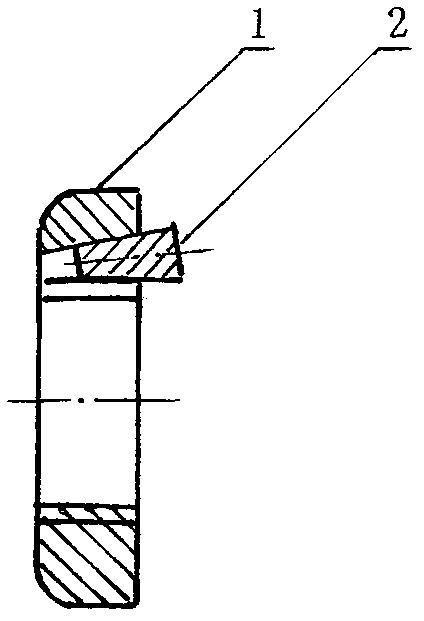

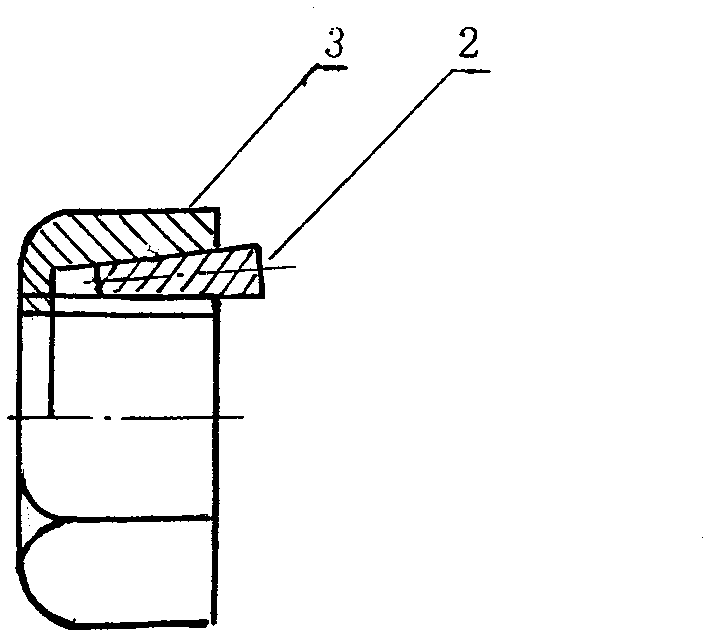

[0034] Such as figure 1 figure 2 image 3 As shown, stick the tapered needle 2 to the deep end of the one-way force groove of the nut body 1 and 3 with butter and glue, and the tapered needle 2 part is exposed to the tapered needle anti-theft nut.

Embodiment 2

[0036] Such as Figure 4 As shown, screw the end surface of the nut body 1, which is the exposed part of the cone needle 2, into the exposed part of the bolt 4 at the end of the installed common nut 5, and the cone needle 2 is screwed to the tail end of the common nut 5 following the nut body 1 .

Embodiment 3

[0038] Such as Figure 5 , as shown, tighten the nut body 1 with a wrench until the exposed part of the taper needle 2 is squeezed into the one-way force groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com