Hydraulic cylinder device with sealing gap adjusting structure

A technology to adjust the structure and seal the gap, which is applied in the field of hydraulic cylinder devices, which can solve the problems of low working pressure of hydraulic cylinders, uncompensated sealing performance, large expansion of the cylinder body, etc., and achieve the effect of reducing the deviation of expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

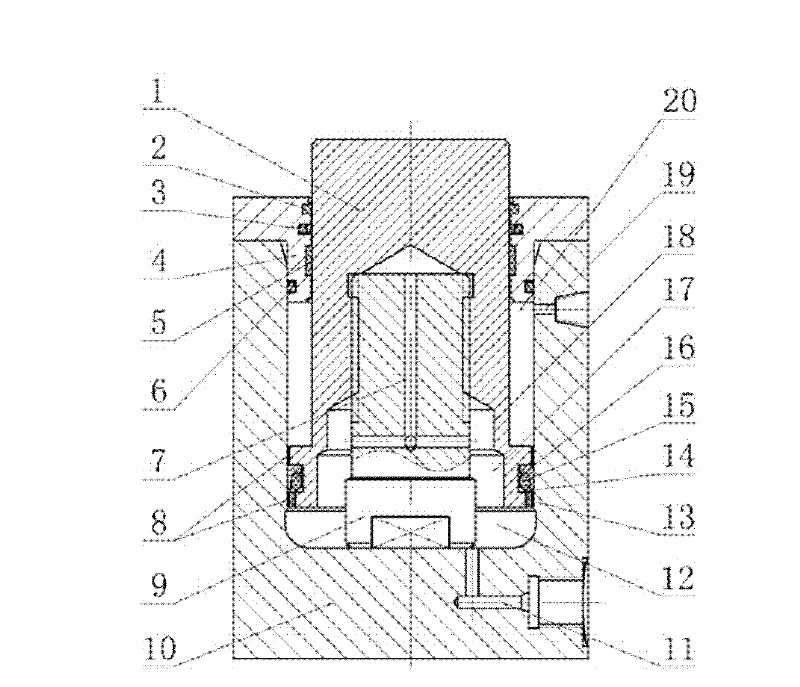

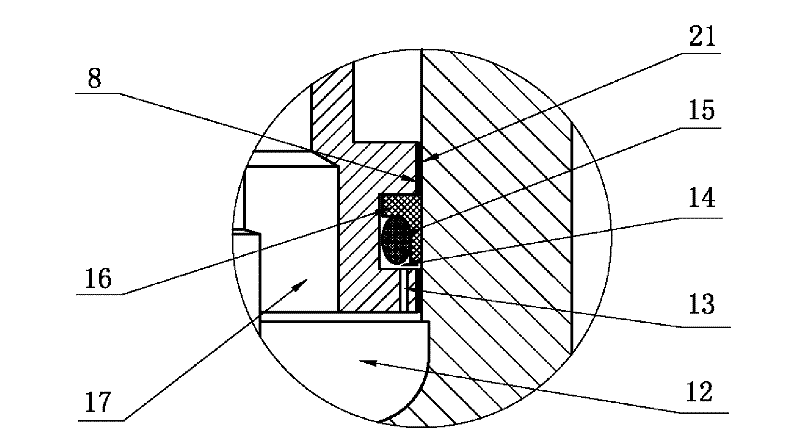

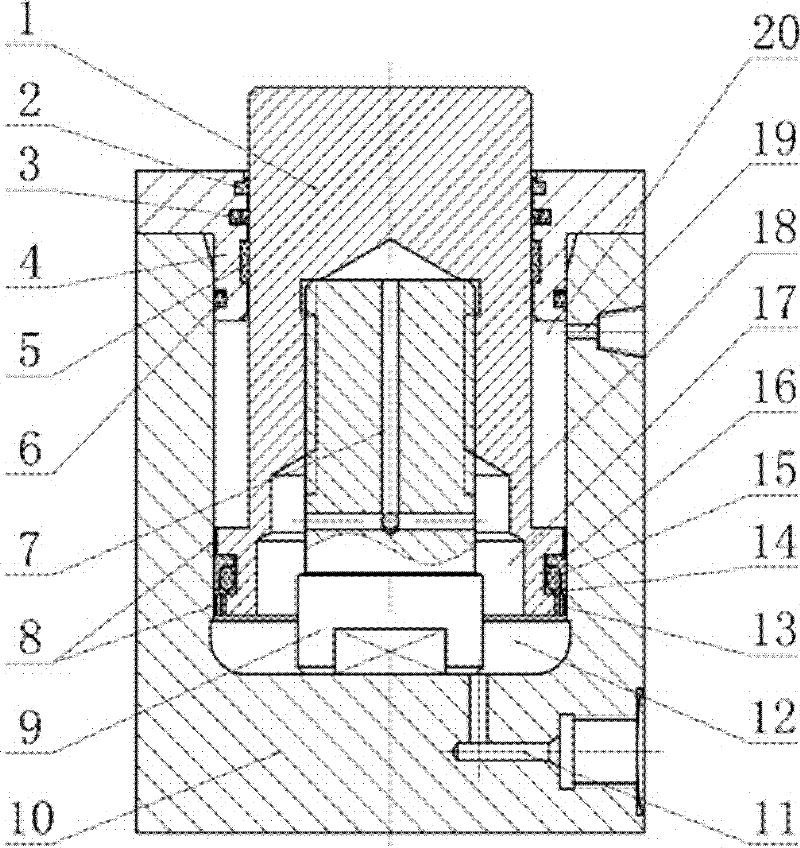

[0018] Such as figure 1 As shown, the hydraulic cylinder device with a sealing gap adjustment structure includes a piston 1 and a hydraulic cylinder block 10 . The bottom of the hydraulic cylinder block 10 , that is, the rodless side of the hydraulic cylinder block 10 is provided with an oil inlet 11 . The upper part of the hydraulic cylinder block 10, that is, the rod side of the hydraulic cylinder block 10 is equipped with a hydraulic cylinder cover 4, and the hydraulic cylinder cover 4 is equipped with a dust-proof ring 2, a sliding seal 3 on the cylinder cover, a guide ring 5 on the cylinder cover, and a seal on the cylinder cover. Fixed seal 6. The assembled piston 1 assembly is installed on the cylinder body 10, the dustproof ring 2, the sliding seal on the cylinder head 3, the guide ring 5 on the cylinder head, and the fixed seal 6 on the cylinder head are respectively installed in the sealing grooves made on the cylinder head 4 , and the cylinder head 4 and the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com