Luminance testing device

A testing device and technology for brightness, applied in the direction of testing optical performance, optics, instruments, etc., can solve the problems of unsatisfactory brightness test effect, poor mobility and flexibility, etc., and achieve the effect of fast brightness measurement and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

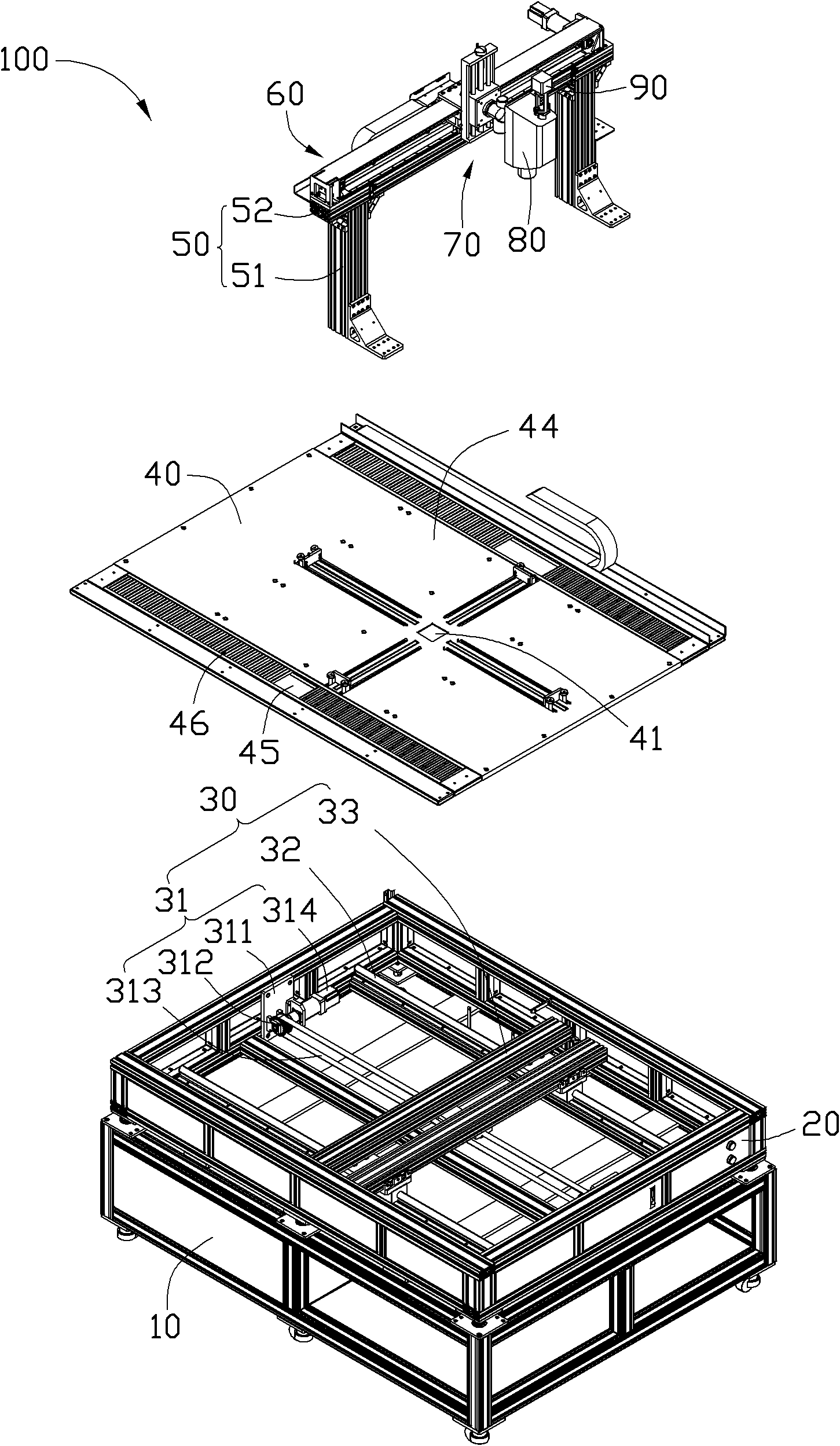

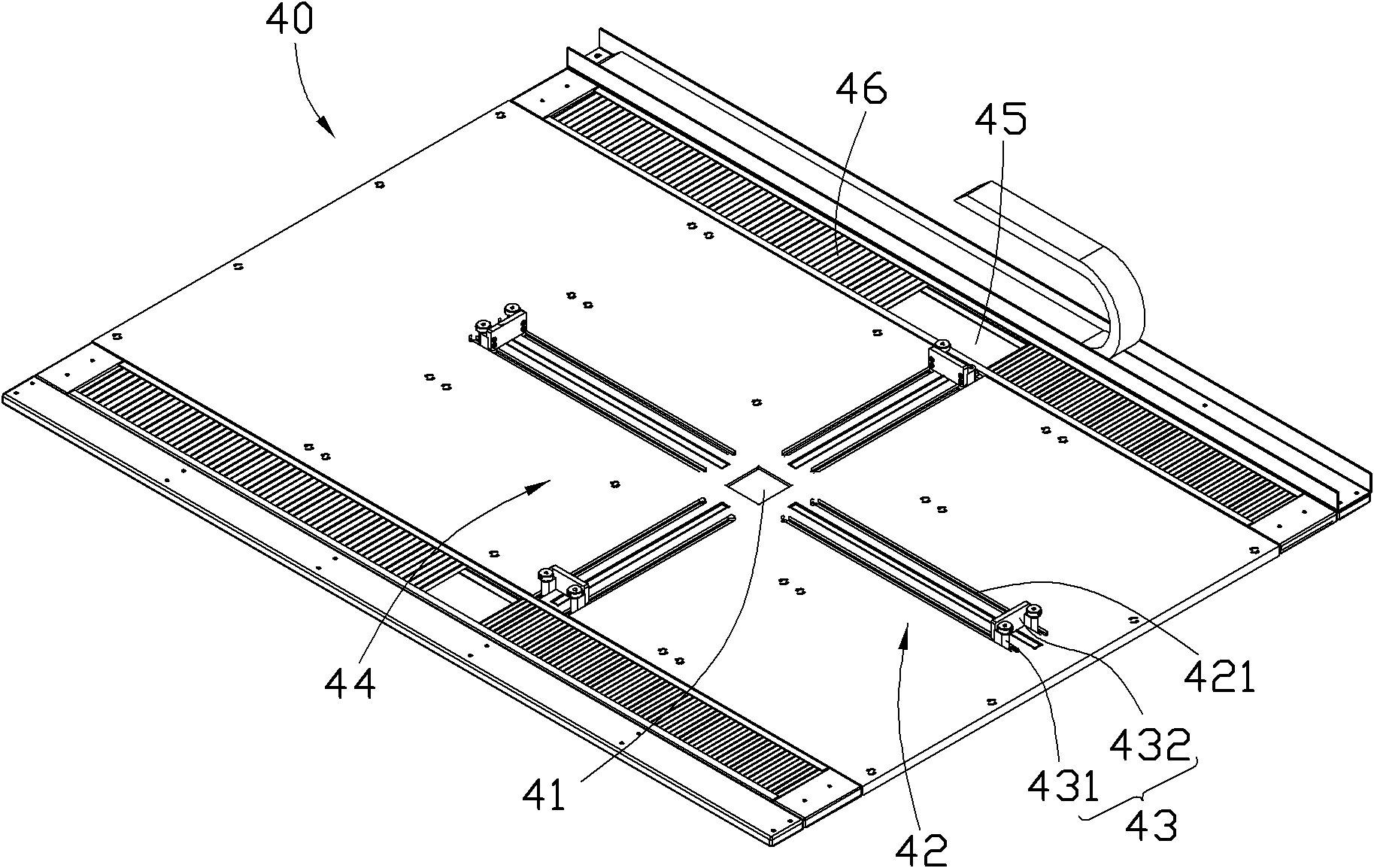

[0015] Please refer to figure 1 A preferred embodiment of the present invention provides a brightness testing device 100 for testing the brightness of a backlight assembly. The luminance testing device 100 includes a base 10, a workbench 20, a first driving mechanism 30, a bearing mechanism 40, a supporting mechanism 50, a second driving mechanism 60, a third driving mechanism 70, a luminance meter 80, and a sensor 90 .

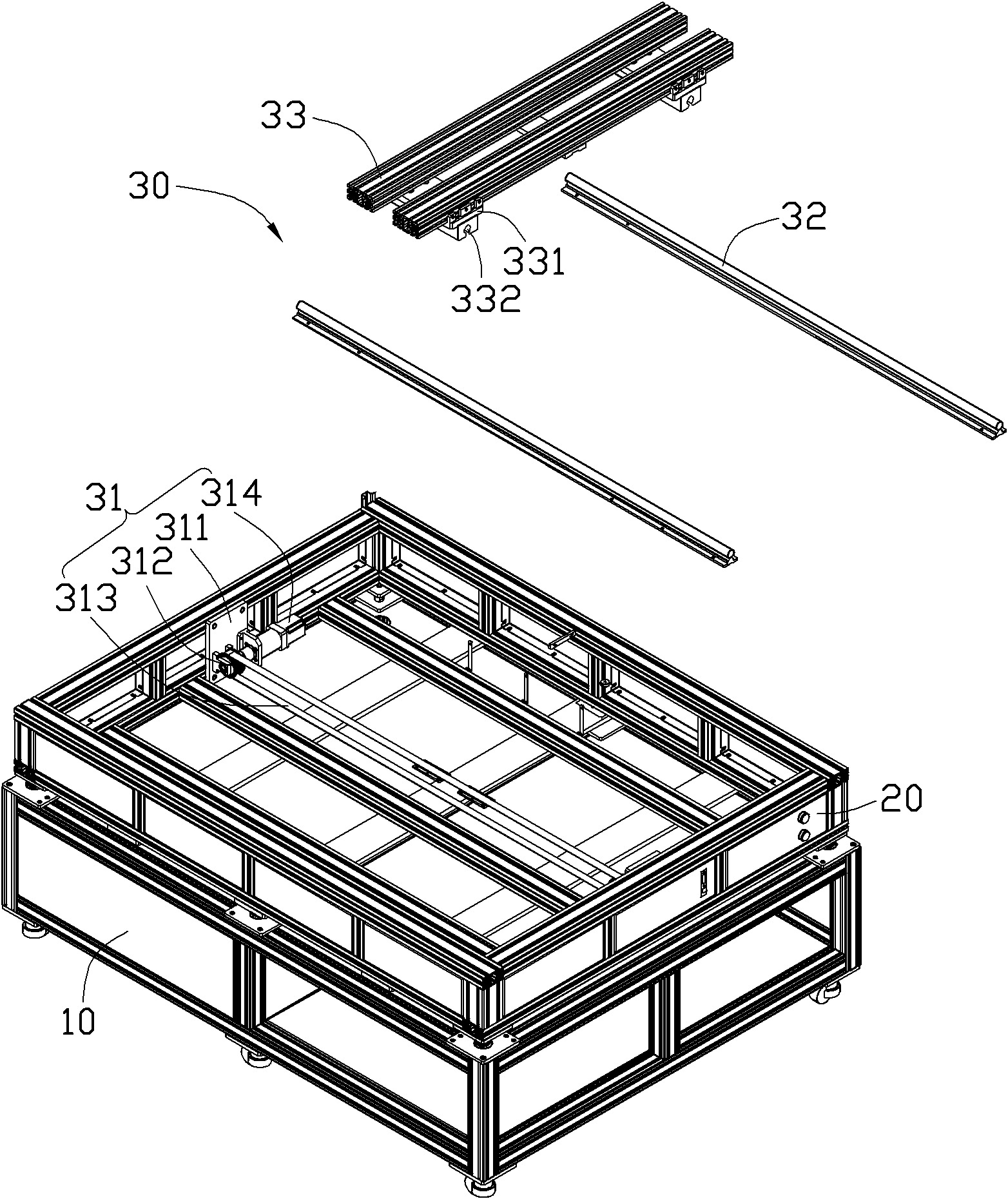

[0016] The base 10 is a rectangular box, and the workbench 20 is a rectangular box with an open top, which is fixedly disposed above the base 10 and is used to house the first driving mechanism 30.

[0017] Please refer to figure 2 , The first driving mechanism 30 includes a first driving part 31, two first sliding rails 32 and two first sliding parts 33. The first driving part 31 includes two first fixing plates 311, two first pulleys 312, a first belt 313 and a first motor 314. The first fixing plate 311 is oppositely arranged in the workbench 20 and perpendi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap