DC motor with insulating frame structures

A DC motor and insulating frame technology, which is applied in the shape/style/structure of winding insulation, etc., can solve the problems of reducing the winding speed of the motor, reducing the area of the motor slot, and increasing the fullness of the slot, so as to reduce the fullness of the slot and improve the performance, the effect of increasing the motor slot area

Inactive Publication Date: 2012-07-18

MIDEA GRP CO LTD

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The insulating frame structure of the DC motor currently used has no insulating frame fixing structure. The insulating structure is placed inside the motor casing as a whole, and the wire slots are all placed inside the motor casing, which greatly reduces the area of the motor slot and leads to an increase in slot fullness. , reduce the winding speed of the motor; and the insulation frame does not have a Hall installation position, and the Hall installation is flush, so that the Hall must increase the length of the permanent magnet for effective induction tiles, which increases the cost, and due to the insulation It is very inconvenient to check

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

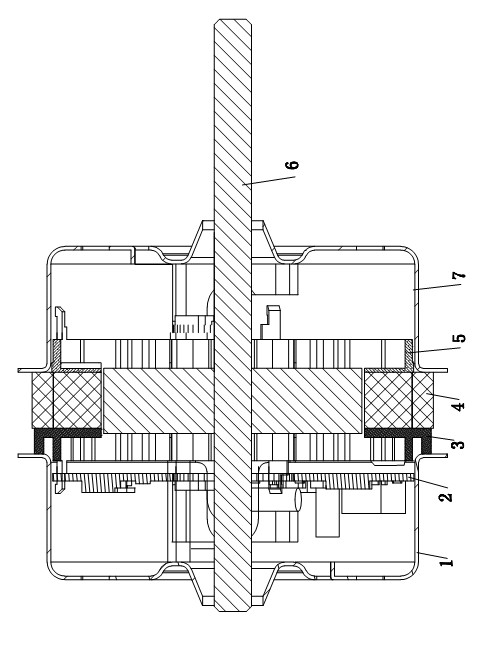

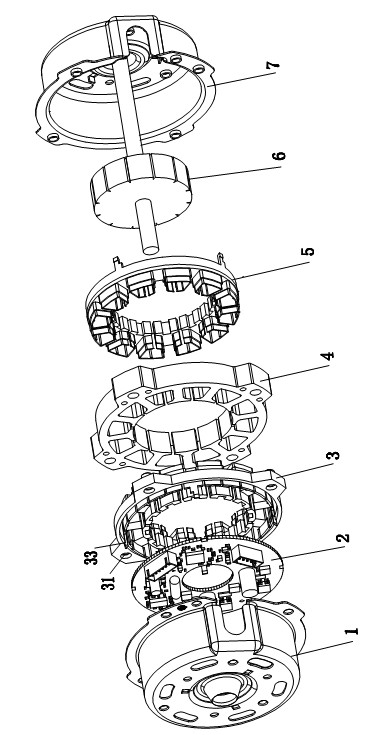

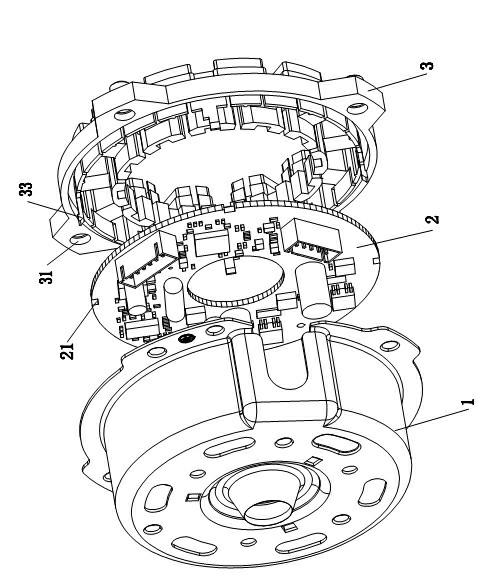

The invention relates to a DC motor with insulating frame structures. The DC motor comprises an upper casing, a control board, an upper insulating frame, a stator iron core, a lower insulating frame, a rotor and a lower casing, wherein the upper and the lower insulating frames are sleeved in the stator iron core; and the upper and the lower casings are matched to form a cavity for mounting the control board, the upper insulating frame, the stator iron core, the lower insulating frame and the rotor. The DC motor is characterized in that the control board is clamped on the upper insulating frame; slots, wire dividing strips, Hall mounting positions, a ring-shaped wire passing slot and fixing positions are arranged on the upper insulating frame; mounting holes are formed on the stator iron core; the fixing positions are embedded into the mounting holes of the stator iron core; the ring-shaped wire passing slot is formed on the edge of the upper insulating frame; the bottom edge of the upper casing is pressed on the ring-shaped wire passing slot; and lug bosses of the upper casing are embedded into the slots of the upper insulating frame. By adopting the DC motor, the mounting concentricity of the insulating frames is improved, and the problem of poor Hall position inductor is solved; and as the ring-shaped wire passing slot is moved to the edge of the upper insulating frame from the inner part of the casing, the area of a motor slot is increased, the slot fill factor can be effectively reduced, and the wire winding speed and the performance of the whole motor can be improved.

Description

technical field [0001] The invention relates to a direct current motor with an insulating frame structure, in particular to a winding structure of a stator iron core suitable for the direct current motor. Background technique [0002] The insulating frame structure of the DC motor currently used has no insulating frame fixing structure. The insulating structure is placed inside the motor casing as a whole, and the wire slots are all placed inside the motor casing, which greatly reduces the area of the motor slot and leads to an increase in slot fullness. , reduce the winding speed of the motor; and the insulation frame does not have a Hall installation position, and the Hall installation is flush, so that the Hall must increase the length of the permanent magnet for effective induction tiles, which increases the cost, and due to the insulation It is very inconvenient when checking. Contents of the invention [0003] The object of the present invention is to provide a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K3/34

Inventor 黄坤河廖启国彭颖卿汪志刚杜舜杰

Owner MIDEA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com