Improved air cylinder used on clutch booster

A booster and clutch technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of hydraulic cylinder sealing ring wear, unstable spring positioning, insufficient air cylinder structure, etc., and prolong the service life. , good positioning, not easy to offset and shift the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

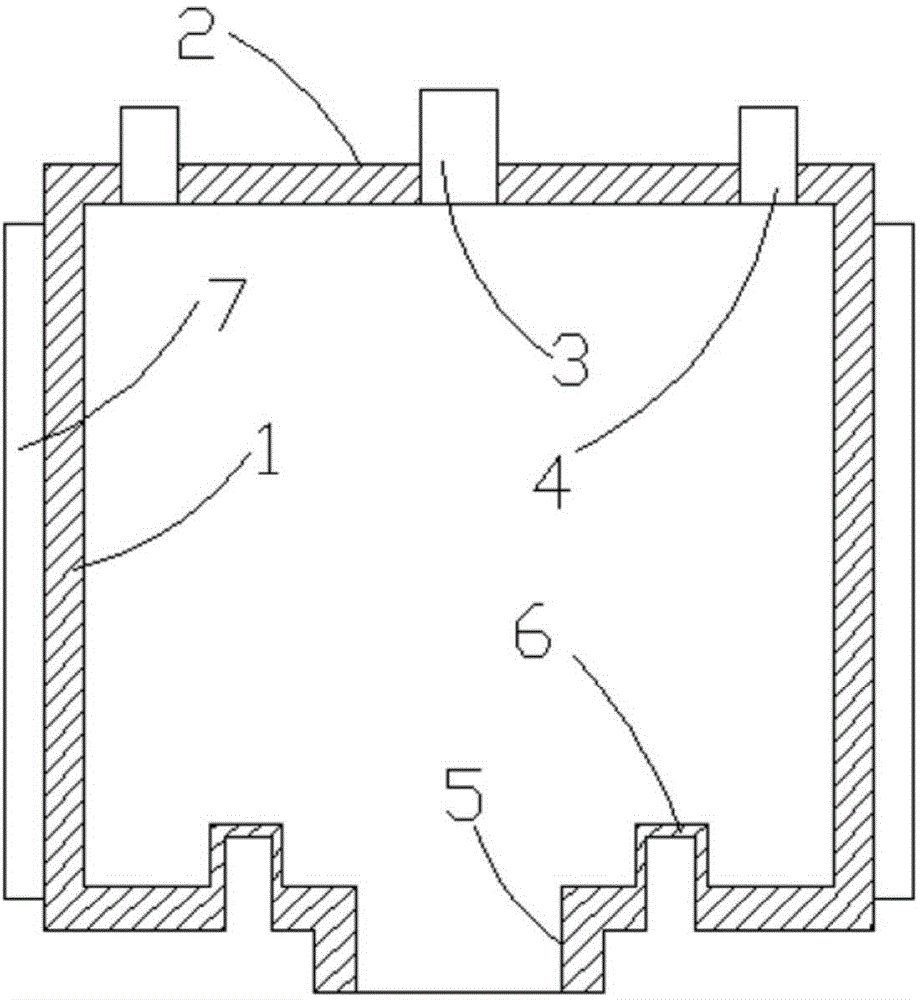

[0018] Such as figure 1 As shown, the present invention relates to an improved cylinder for a clutch booster, comprising a cylindrical cylinder block 1, characterized in that: a mounting hole 3 is formed in the middle of the top surface 2 of the cylinder block 1, and 2 is formed at the outer edge A ventilation slot 4 with the same orientation as the mounting hole 3; an externally protruding outlet end 5 is formed on the bottom surface of the cylinder block 1, and an internally protruding positioning column 6 with internal threads is formed on the bottom surface; Air guide groove, the cylinder block 1 is made of aluminum alloy, the cylinder block 1 is formed by one-time die-casting, the air guide groove 7 is welded on the outer wall of the cylinder block 1, the air guide groove 7 is connected with the cylinder The body 1 is integrally formed, and a hose is connected between the ventilation groove 4 and the air guide groove 7 .

[0019] The above is a detailed introduction to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com