Piezoelectric power generation device based on excitation of fluidic micro oscillator

A piezoelectric power generation and power generation device technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the trouble of replacing batteries, energy waste, limited battery energy, etc. problem, to achieve the effect of improving the utilization efficiency, eliminating the need to replace the battery, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific structure, principle and working process of the present invention will be described in detail below with reference to the accompanying drawings.

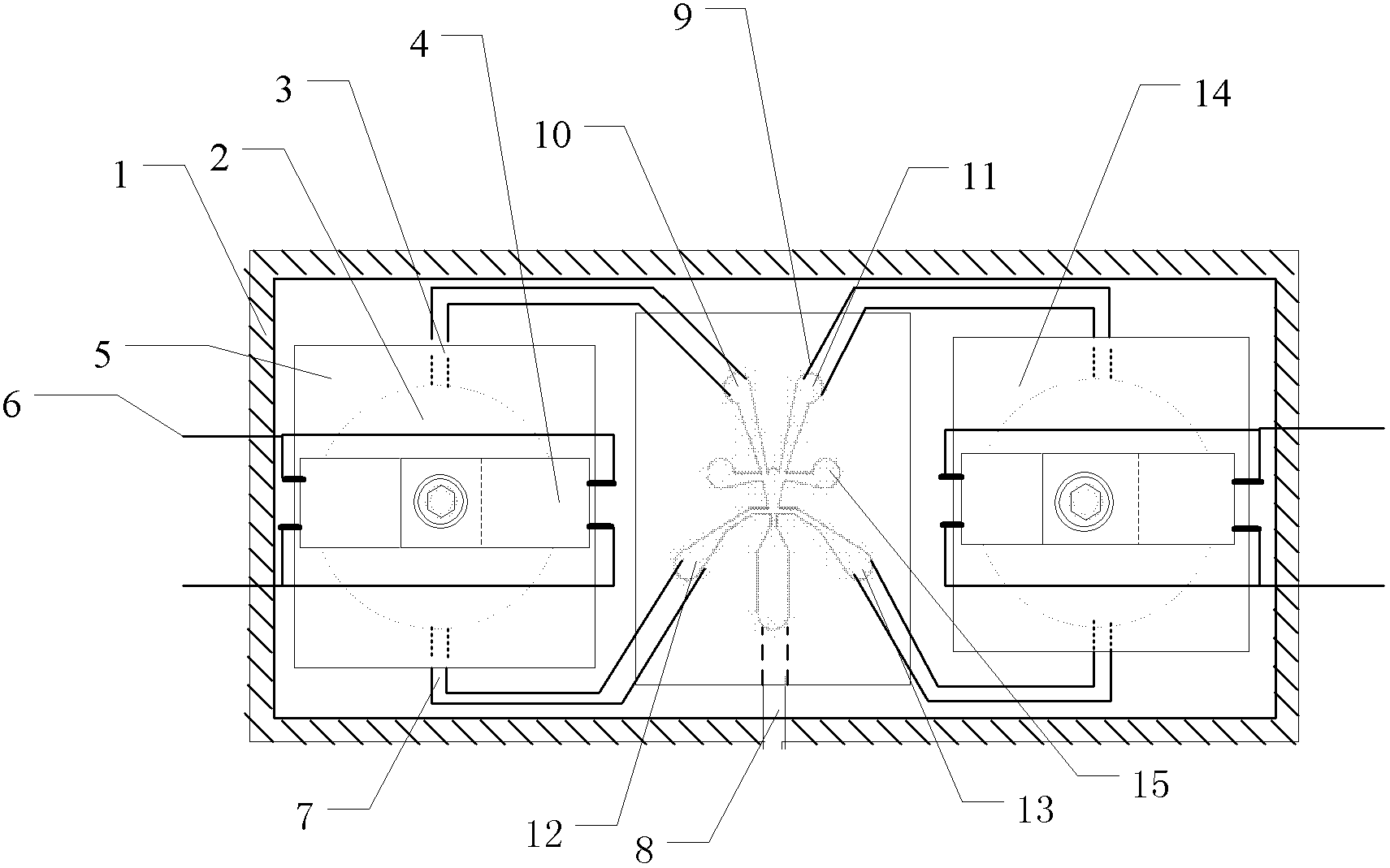

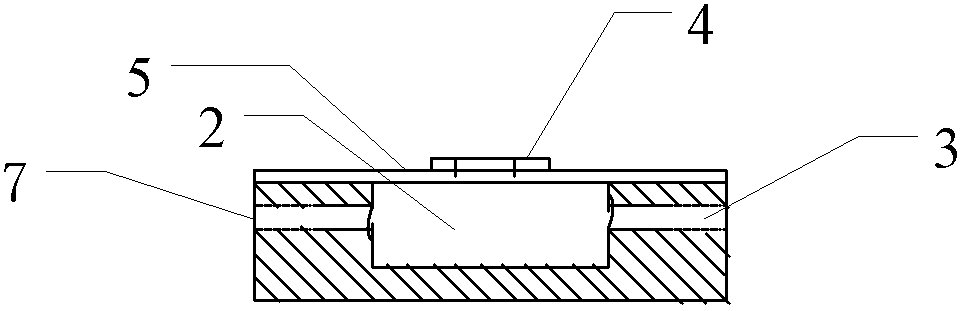

[0012] Such as figure 1 As shown, the piezoelectric power generation device based on jet micro-oscillator excitation provided by the present invention includes a housing 1, a bistable jet element 9, a first oscillation cavity 2, a second oscillation cavity 14 and an output circuit 6. The bistable jet element 9 is installed in the middle of the bottom of the housing 1, and the first oscillation cavity 2 and the second oscillation cavity 14 are symmetrically installed on the left and right sides of the bistable jet element. The bistable jet element 9 is provided with a bistable jet element air inlet 8, a bistable jet element first output port 10, a bistable jet element second output port 11, a bistable jet element first control port 12, and a bistable jet element. The jet element second control port 13 and the bistabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com