Production method of cavity PCB plate

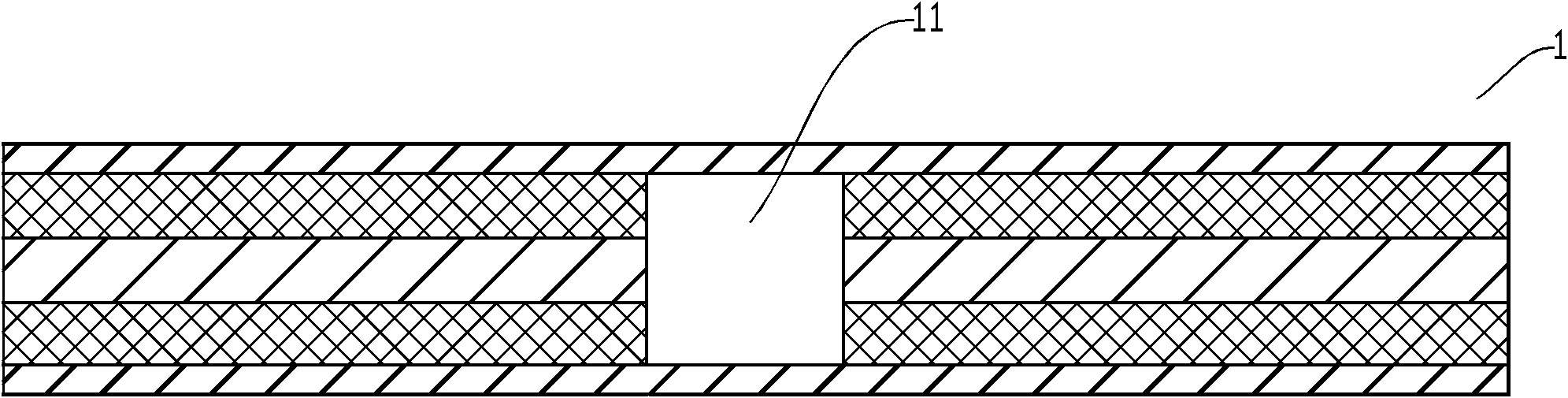

The technology of a PCB board and production method is applied in the field of cavity PCB board production, and can solve problems such as the size and shape of the cavity 11 not conforming, the difficulty of producing the cavity PCB board, and the flattening of the cavity, etc., and the method is convenient to implement, Less process, accurate size and depth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

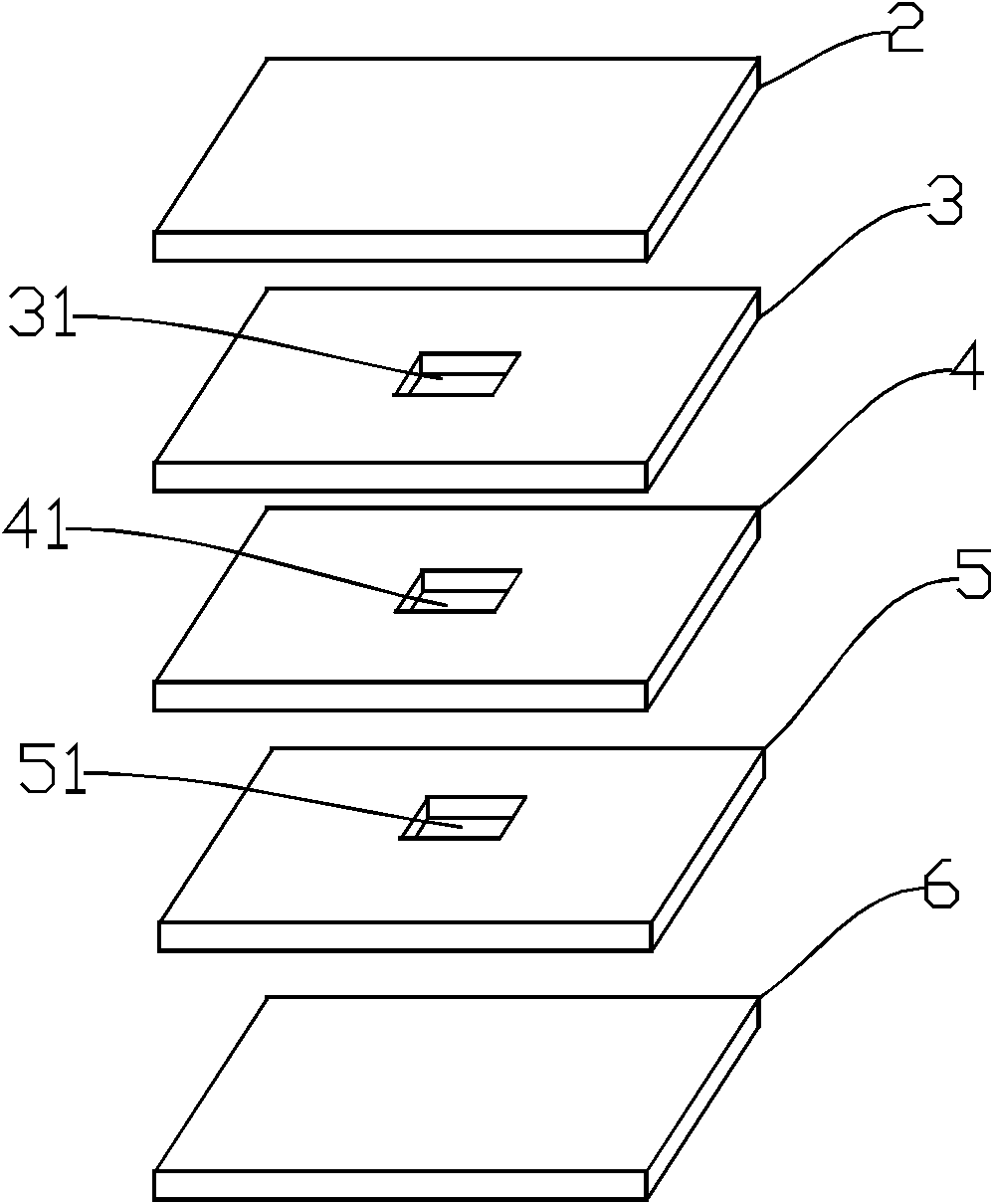

[0027] The production method of cavity PCB board comprises the following steps: as Figure 5 as shown,

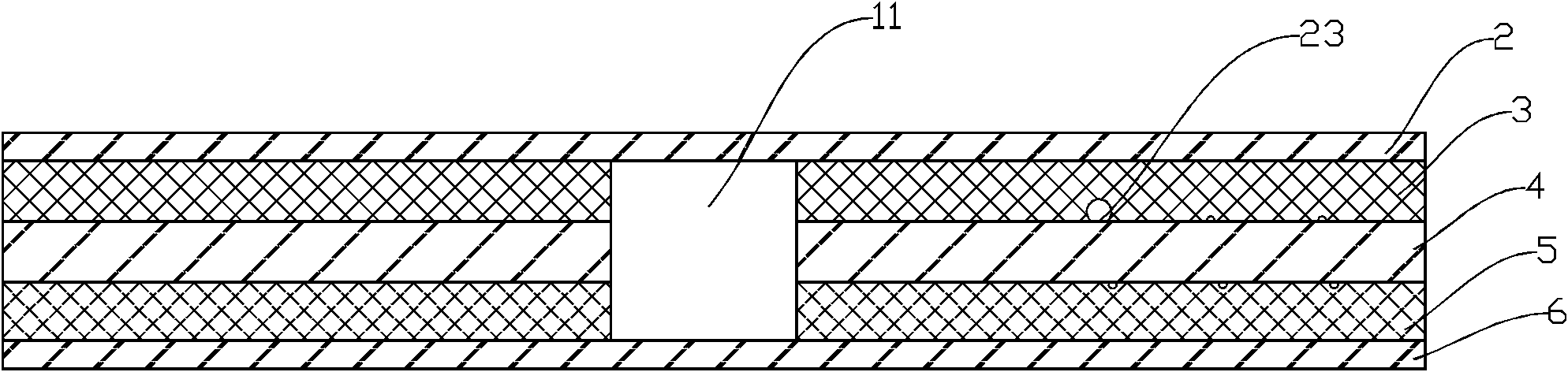

[0028] a. The inner core board 4 is provided with a window 41 . A first prepreg 3 is pasted on the upper surface of the inner core board 4 , and a window 31 is opened in the first prepreg 3 . A second prepreg 5 is pasted on the lower surface of the inner core board 4 , and a window 51 is opened in the second prepreg 5 . Both the window 51 and the window 31 are aligned with the position of the window 41 .

[0029] b. Attaching the first outer layer core board 2 on the upper surface of the first prepreg 3 . For the convenience of description, marking lines 21 are marked on the upper surface of the first outer core board 2 , and the marking lines 21 do not need to be marked in actual production. The marking line 21 has the same size as the window 51 , the window 31 and the window 41 , and their positions are aligned. On the lower surface of the second prepreg 5, a second ...

Embodiment 2

[0039] On the basis of Embodiment 1, a piece of copper foil is provided between the first auxiliary board 91 and the first bonding pad 101 during lamination. A piece of copper foil is also disposed between the second auxiliary board 92 and the second bonding pad 102 . This can prevent the dust of the pressing pad from contaminating the board surface, and can also prevent the outer core board from being unevenly heated and affecting the performance of the circuit board.

Embodiment 3

[0041] On the basis of Example 1, such as Figure 7 As shown, a first through hole 22 is drilled on the first outer core board 2 . The first through hole 22 communicates with the cavity 11 . A second through hole 62 is drilled on the second outer core board 6 , and the second through hole 62 communicates with the cavity 11 . Moreover, the first through hole 22 and the second through hole 62 can be arranged in a staggered manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com