Manufacturing method of high-density interconnected printed circuit board

A printed circuit board and high-density interconnection technology, which is applied in the secondary processing of printed circuits, the formation of electrical connections of printed components, and the application of non-metallic protective layers. Pollution control costs and other issues to achieve the effect of avoiding poor conduction, improving yield, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

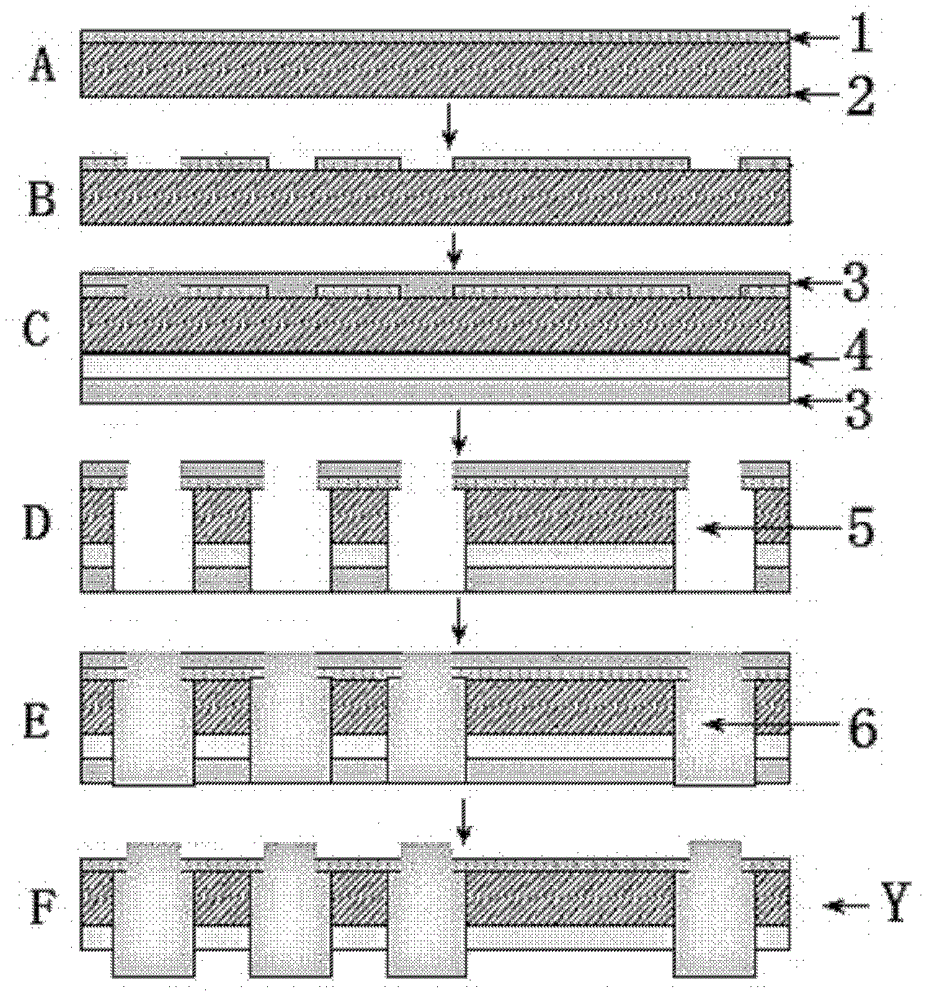

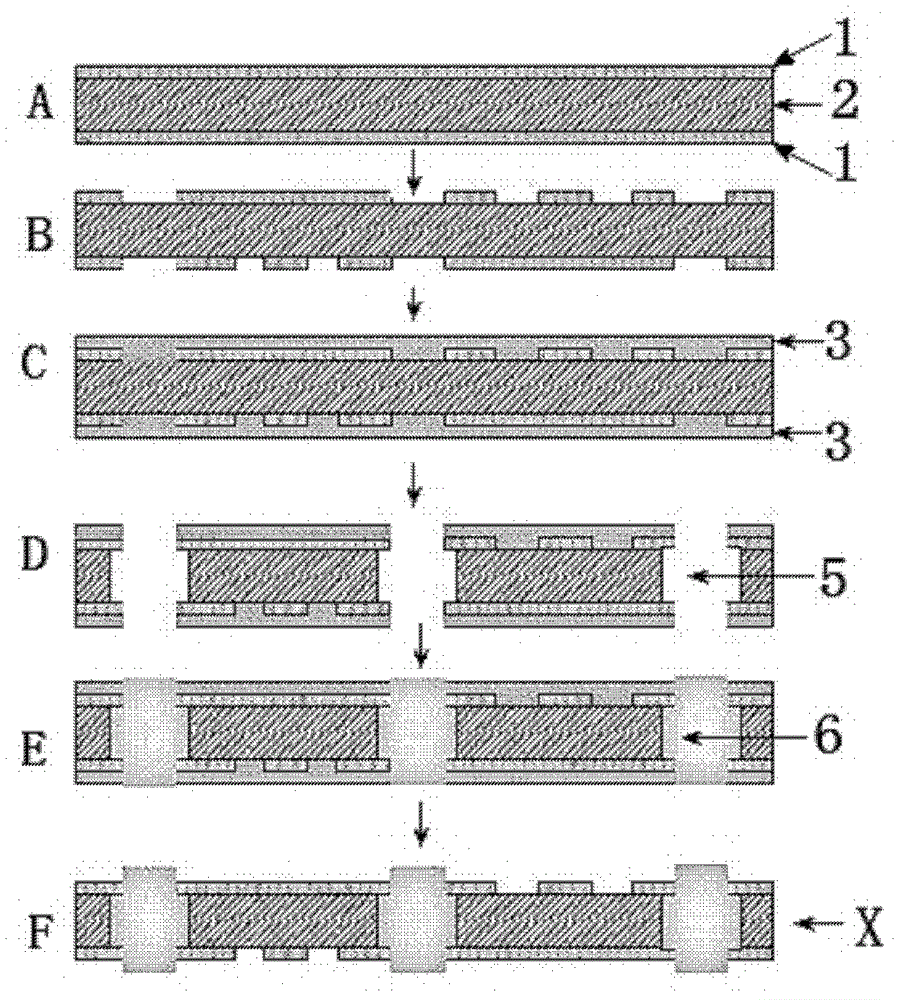

[0029] Embodiment: A method for manufacturing a high-density interconnected printed circuit board. The high-density interconnected printed circuit board consists of a core structure X located in the middle, several intermediate structures Y located on both sides of the core structure, and an outermost The outer structure Z is superimposed and heat-pressed, such as Figure 4 shown;

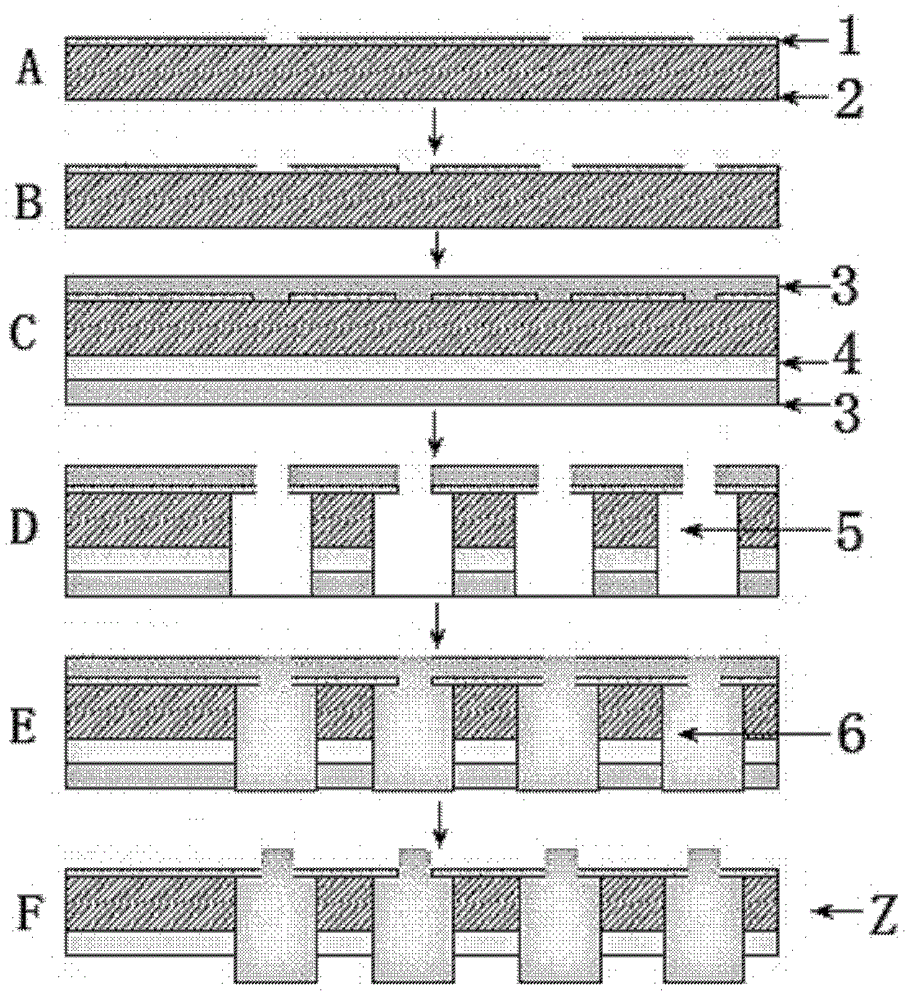

[0030] Wherein, the preparation method of the outer layer structure Z is as follows: figure 1 As shown in A-F, the copper foil layer 1 of the single-sided copper foil substrate composed of the copper foil layer 1 and the insulating layer 2 is windowed, and then a layer of protective film 3 is pressed on the surface of the copper foil layer 1 and at the same time A layer of adhesive film 4 and a layer of protective film 3 are pressed on the surface of the insulating layer 2. The protective film 3 is located outside the adhesive film 4. A through hole 5 is drilled on the single-sided copper foil sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com