Switch device operating mechanism

A switch device and operating mechanism technology, applied in the direction of contact operating mechanism, electric switch, high-voltage/high-current switch, etc., can solve the problems of easy disengagement of the latch, failure to maintain the closed state, troublesome position adjustment, etc., and achieve easy position Effects of adjustment, high reliability, and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

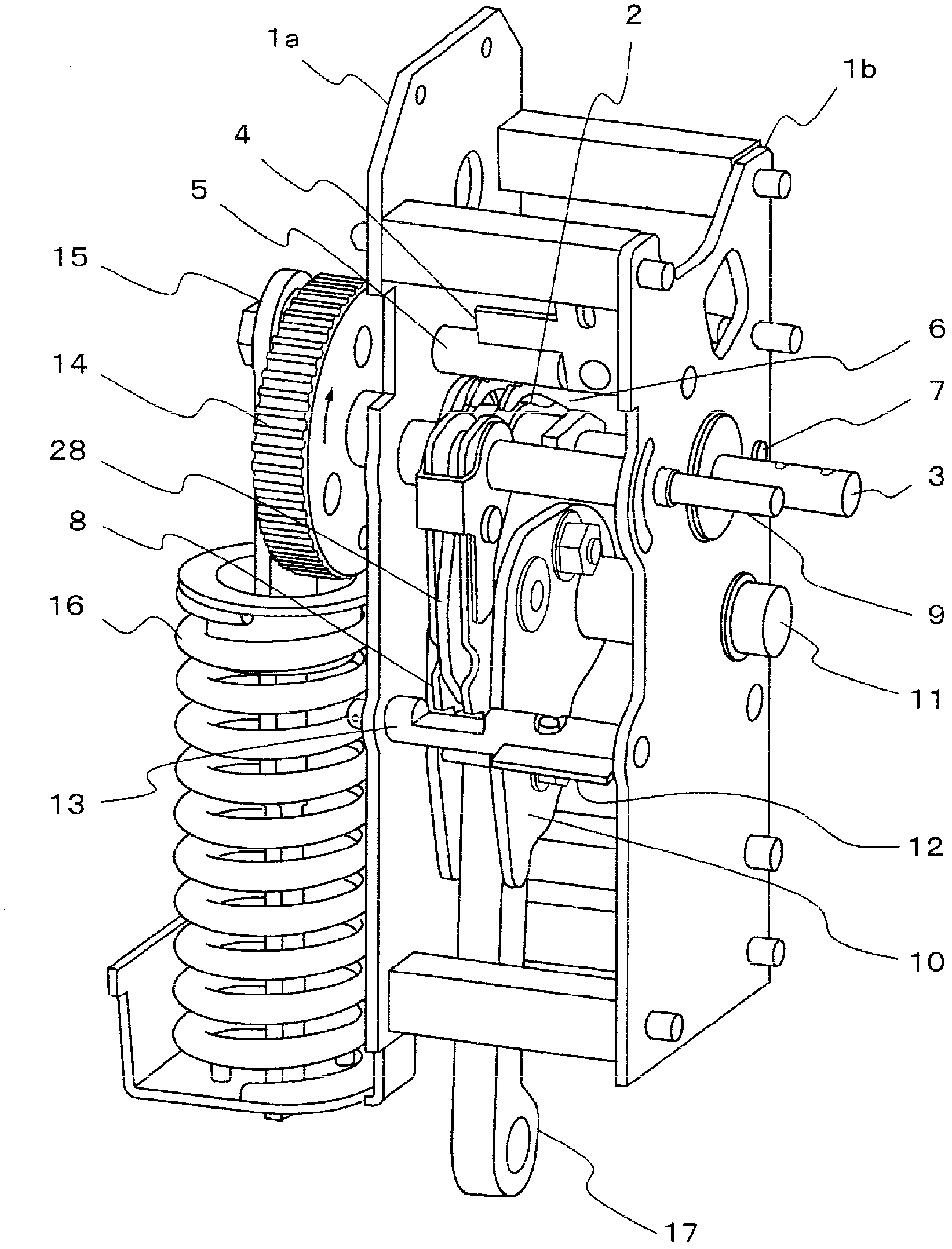

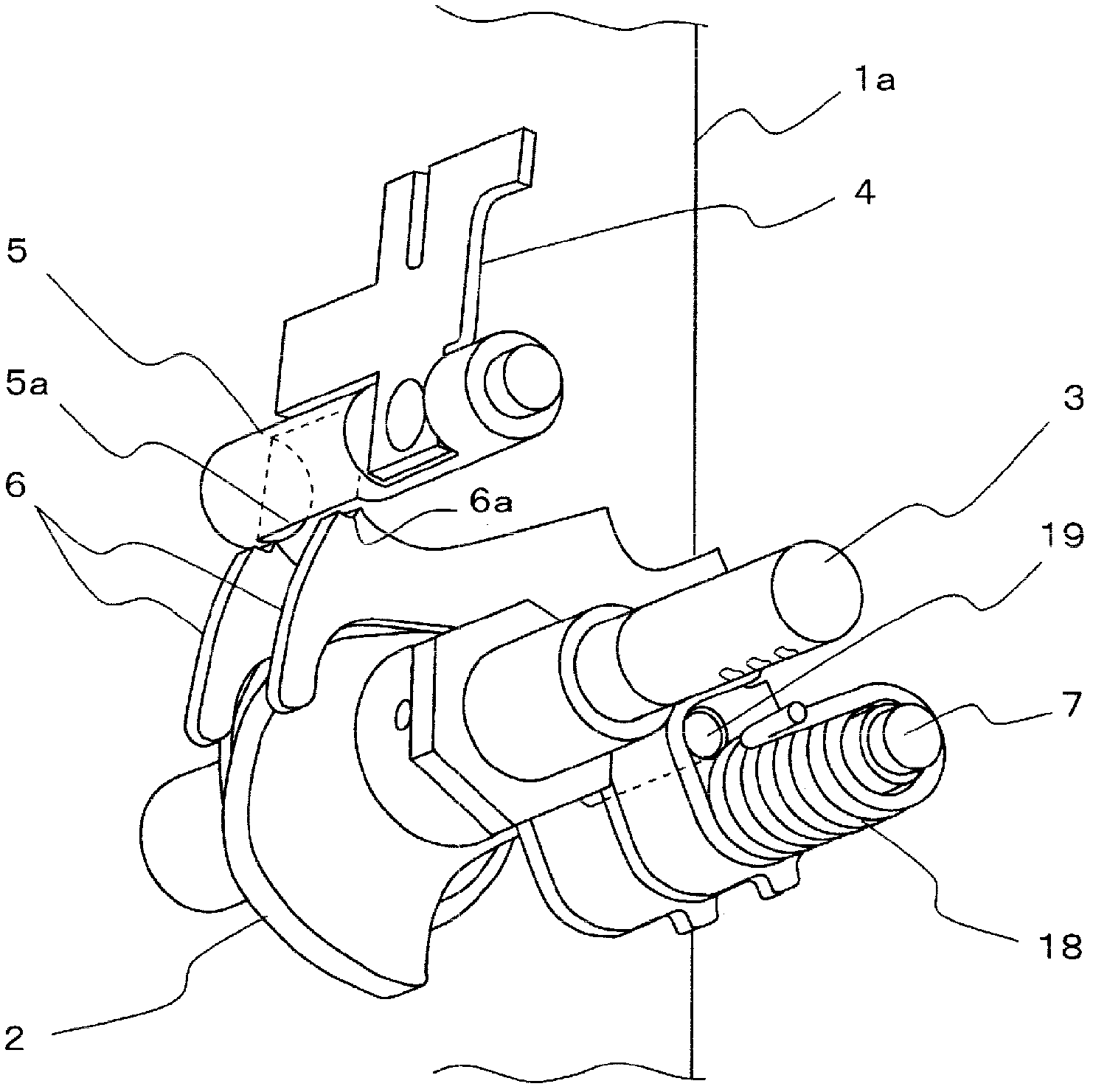

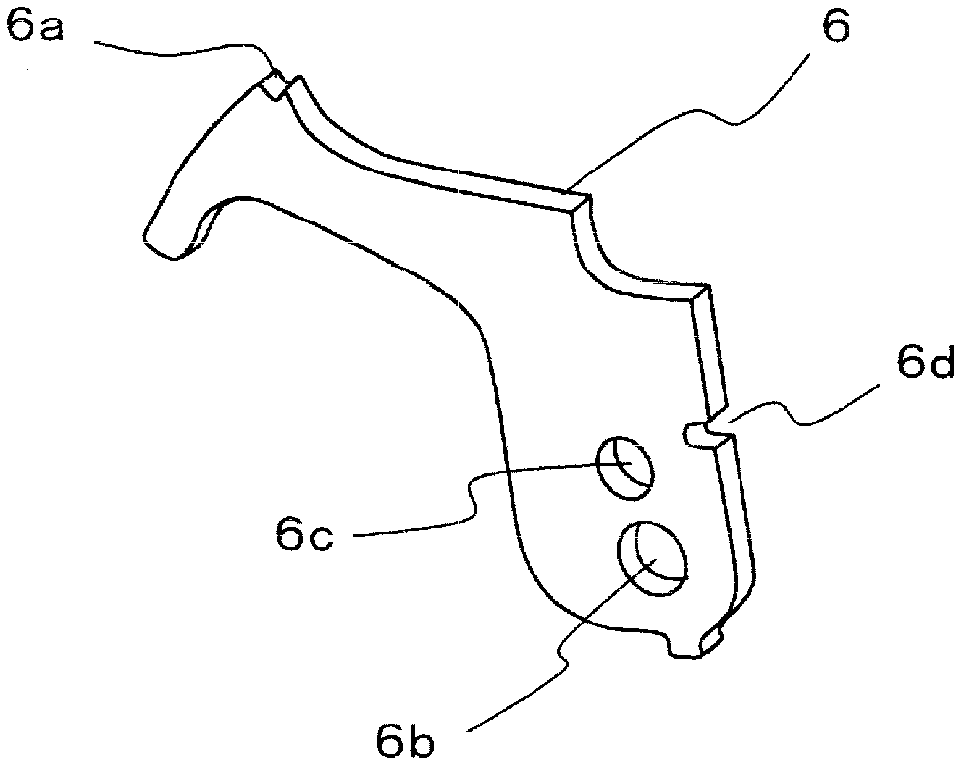

[0027] figure 1 It is a perspective view of the operating mechanism of the switchgear of Embodiment 1. As a switching device, for example, a vacuum circuit breaker using a vacuum valve will be described as an example. First, use figure 1 The perspective view of the figure illustrates the overall structure of the operating mechanism. However, in figure 1 There are also parts that are hidden inside and whose shape is not easy to understand, so, figure 1 It is mainly to explain the arrangement relationship between each component, and for the details of the shape of each part, we will use Figure 2 ~ Figure 6 The partial diagram is described.

[0028] Such as figure 1 As shown, a camshaft 3 is disposed between two frames 1a and 1b having different shapes, and the camshaft 3 is fixedly connected with a cam 2 for transmitting a closing driving force. A first half-moon latch 5 is arranged above the camshaft 3, and a closing lever shaft 7 is arranged behind the camshaft 3, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com