Orthodontic measuring device based on force and torque sensor

A torque sensor and measuring device technology, applied in the field of orthodontics, can solve problems such as poor measurement accuracy, difficulty in mastering by orthodontists, and high cost, and achieve the effects of easy disassembly and assembly, cleaning, disinfection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

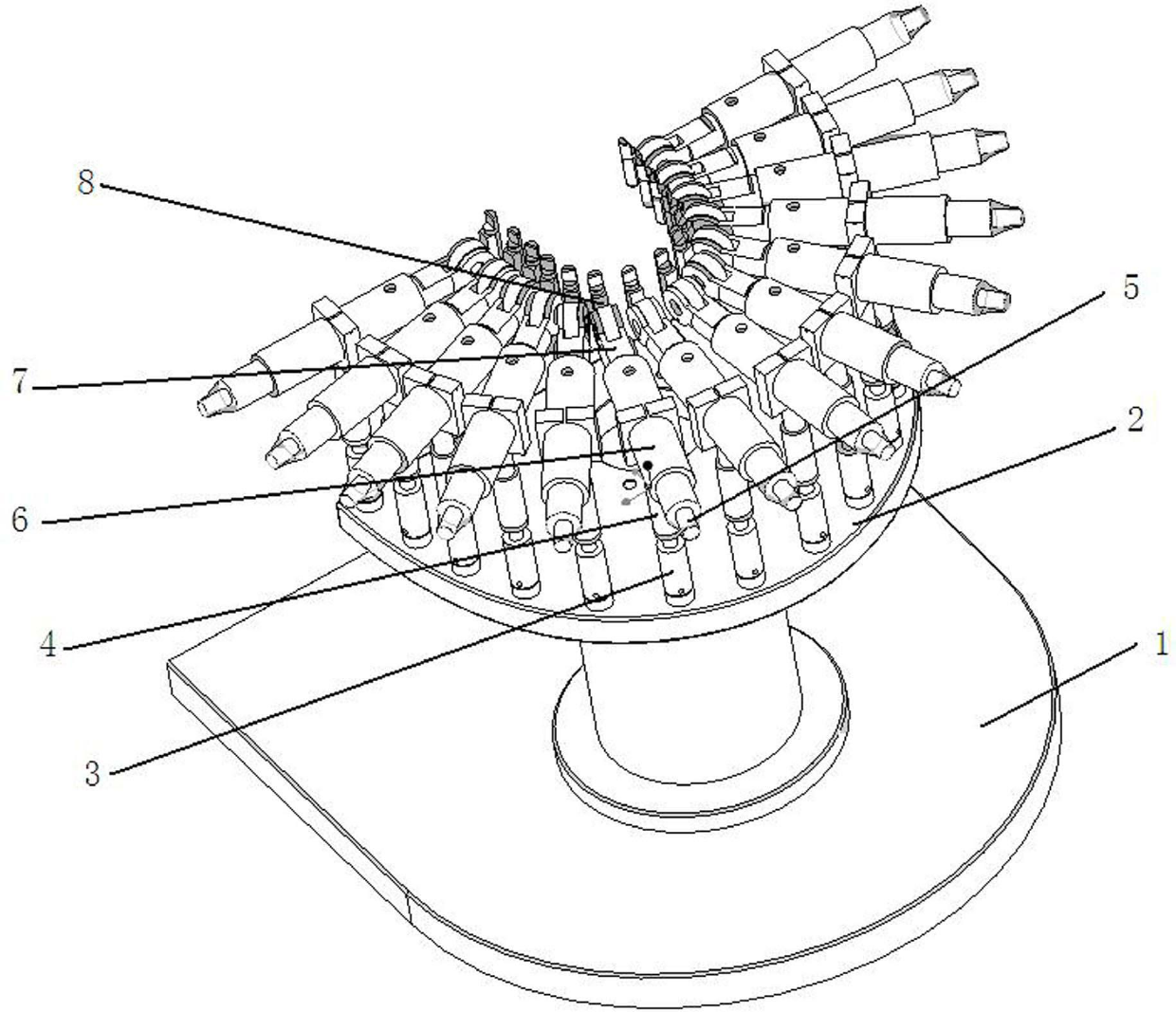

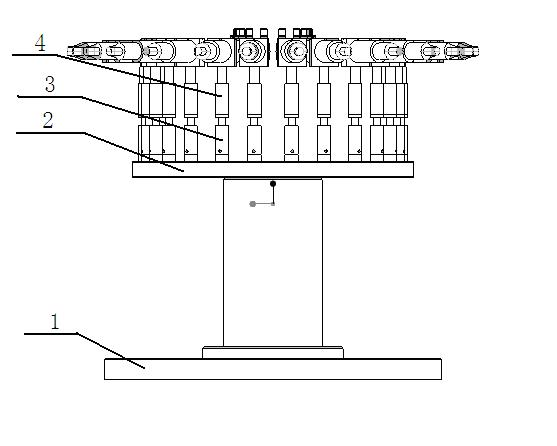

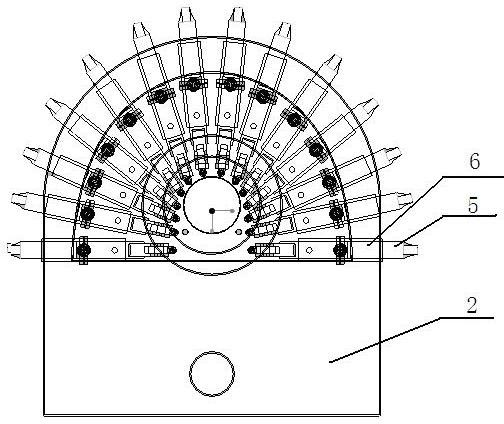

[0022] Such as Figure 1-8 As shown, it includes a support base 1, a fixed chassis platform 2 and main measuring components. The support base 1 is fixedly connected with a fixed chassis platform 2 by bolts. The support base 1 is horseshoe-shaped, and a connecting column is fixedly installed in the center. The fixed chassis platform 2 is fan-shaped, and fourteen fixed columns are fixedly installed on the front end arc edge of the fixed chassis platform 2, and the fixed columns coincide with the distribution positions of the teeth. The main measuring parts include vertical shaft sleeve 3, clamping ring 4, horizontal feed shaft 5, horizontal shaft sleeve 6, YOZ plane r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com