Indigo, and preparation method and processing apparatus thereof

A processing equipment and technology of Indigo Naturalis, applied in the field of medicine, can solve the problems of low content of active ingredient indirubin and lack of preparation methods, etc., and achieve the effects of stable and controllable product quality, improved quality, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

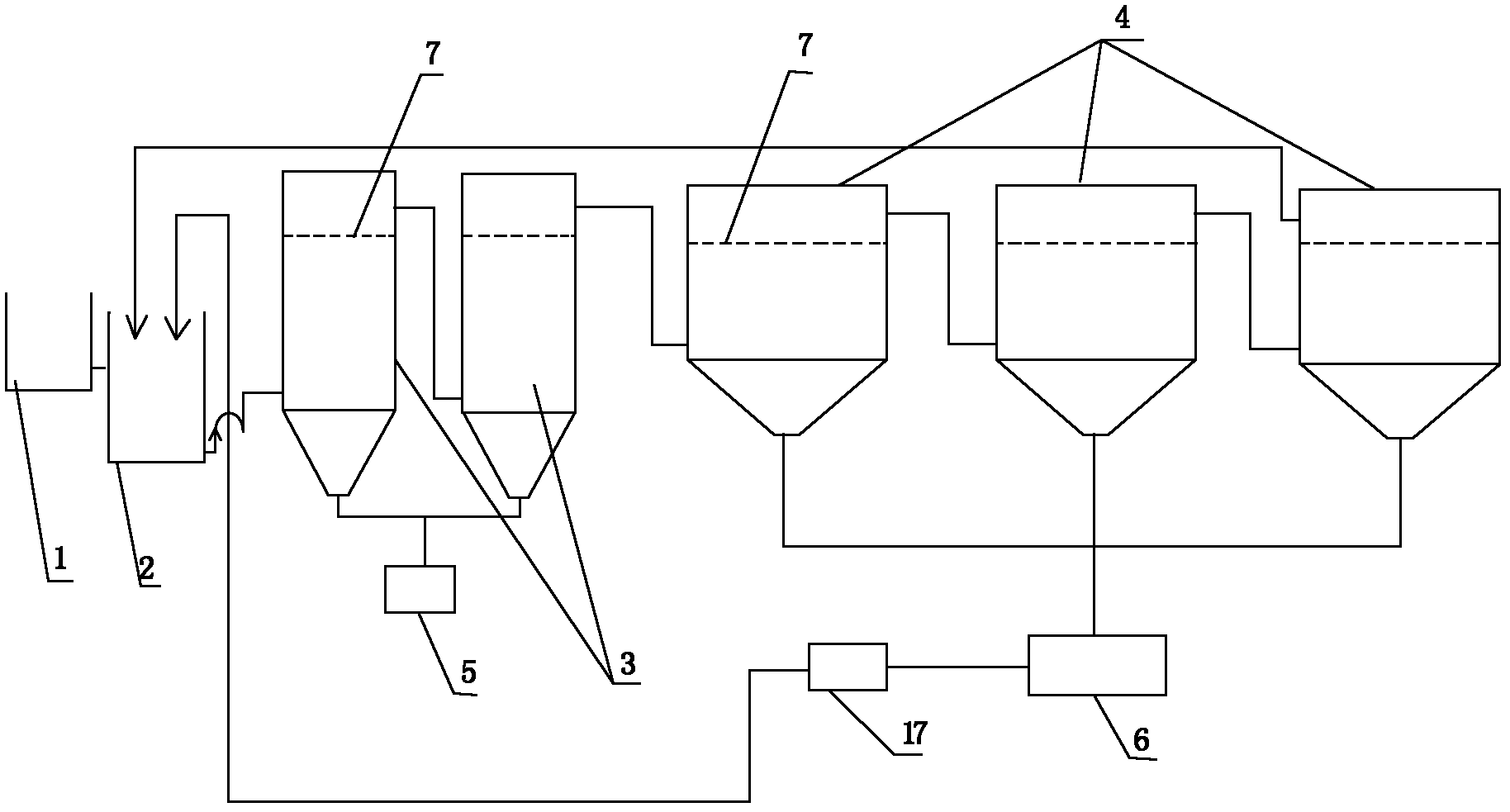

[0033] Example 1 Indigo Naturalis processing equipment of the present invention

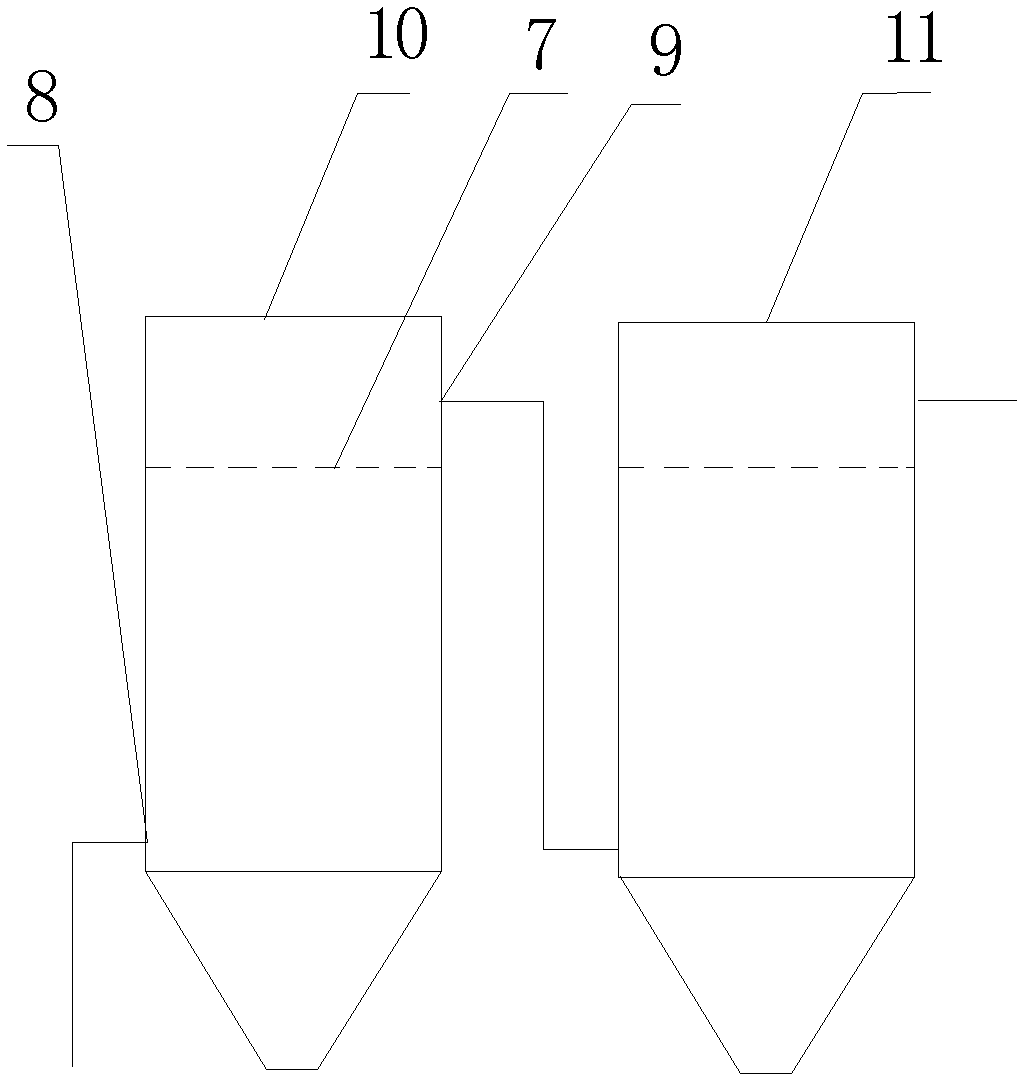

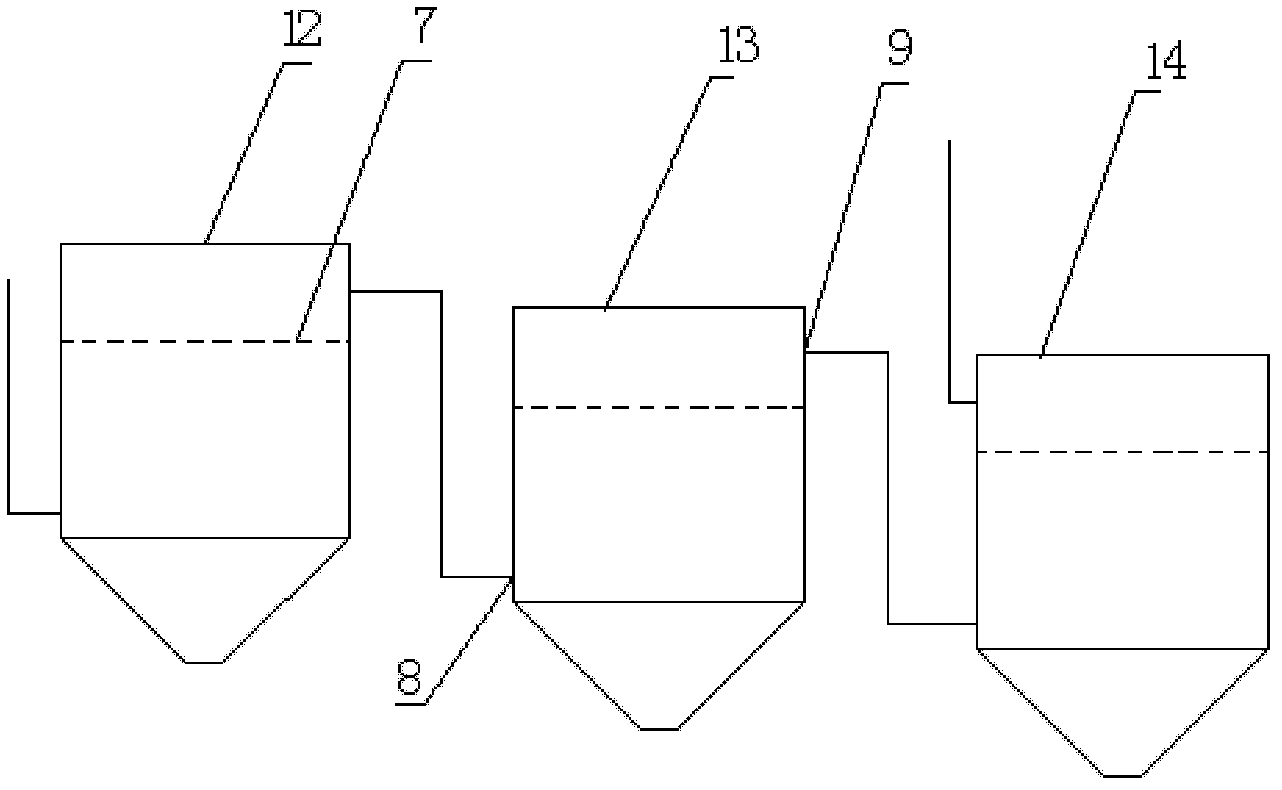

[0034] The present invention provides a Qingdai processing equipment, which includes a raw material tank 1, a liquid mixing tank 2, a waste material tank 5, a collection dryer 6, and it also includes a multi-stage rotary filter purifier 3 and a multi-stage sedimentation separation tank 4; among them, The inner upper end of each stage of rotary filter purifier and sedimentation separation tank is equipped with a filter membrane 7, and the filter membrane 7 is located above the feed port 8 and below the overflow port 9; the bottom of the multi-stage rotary filter purifier 3 and waste The tank 5 is connected; the bottom of the multi-stage sedimentation separation tank 4 is connected with the collection dryer 6; the feed port 8 of the multi-stage sedimentation separation tank 4 is located at the lower end of the sedimentation separation tank; among them, the filter membrane set in each stage of the spin ...

Example Embodiment

[0049] Example 2 Preparation method of Indigo Naturalis of the present invention

[0050] (1) Take the crude indigo, put the crude indigo into the batching tank, add 20 times the amount of water, stir to form a uniform suspension slurry, and then put it in the primary sedimentation tank for coarse sedimentation for 5 minutes; pump the suspension into a first-stage spin filter In the purifier (flow rate is 2 cubic meters / hour), the mixed spinning liquid slowly rises through the 40-mesh filter membrane, and the suspension passing through the filter membrane enters the secondary rotary filter purifier through the overflow port, and the suspension continues to pass 80 mesh filter membrane, the suspension purified by the two-stage rotary filtration purifier, enters the first-stage sedimentation separation tank through the overflow; the suspension of the impermeable filter membrane, at a frequency of 30-40 minutes / time Drain into the waste pool.

[0051] (2) The suspension purified by t...

Example Embodiment

[0053] Example 3 Screening of various parameters in the preparation method of the present invention

[0054] 1. Investigation of the dilution ratio and feed flow rate of crude indigo

[0055] Taking the standard under "Indigo Naturalis" in the 2010 edition of the Pharmacopoeia as an indicator, the dilution ratio and feed flow rate of crude indigo were investigated. The results are shown in Table 1.

[0056] Table 1

[0057]

[0058] It can be seen from the above table that when diluted 5 or 10 times, the production speed is faster and the finished product yield is higher, but the content of indigo and indirubin is low, which does not meet the pharmacopoeia standards; when the dilution is 15-30 times, The material flow rate is 1.5-2.5 cubic meters per hour, and the contents of indigo and indirubin are in line with the pharmacopoeia standards. When the dilution factor is more than 25 times, the production speed is slower. Therefore, the dilution factor should be preferably 15-25 When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com