Bag type dust-collecting built-in bag cage and combined mounting structure of bag cage and filtering bag on tube sheet

A bag-type dust removal and built-in technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of troublesome installation and operation, and achieve the effect of convenient installation and operation and saving height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

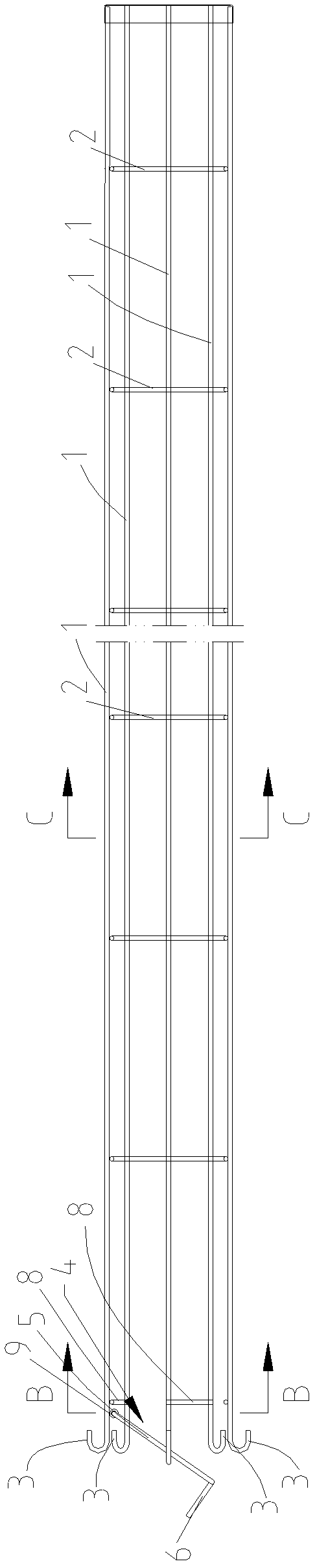

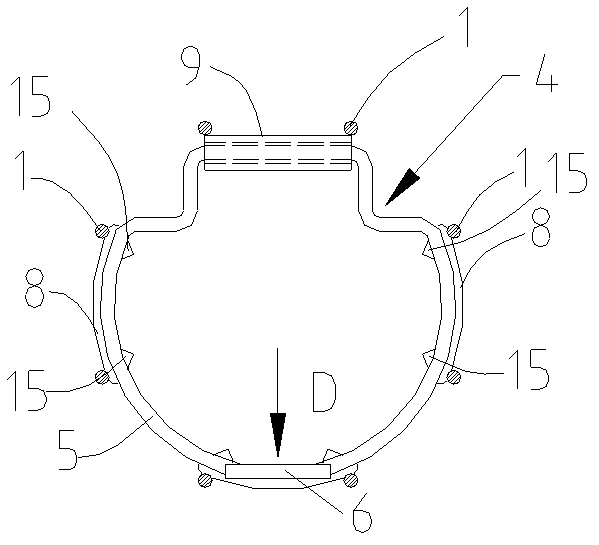

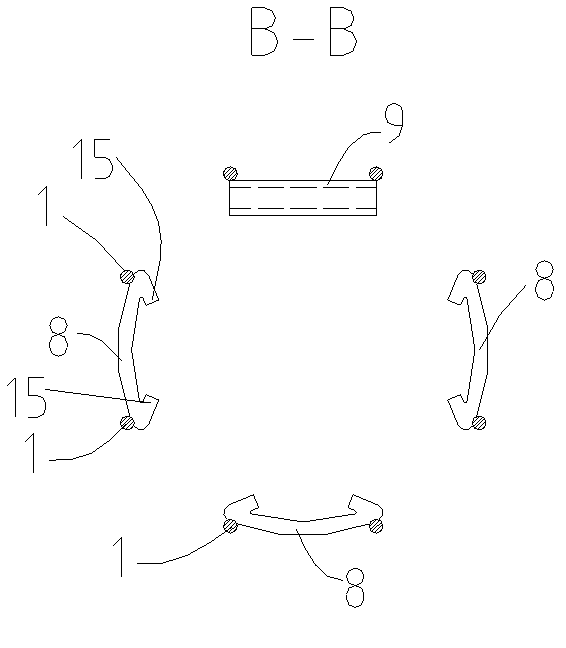

[0018] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] exist Figure 1-6 Among them, a built-in bag cage, including a plurality of vertical ribs 1 arranged at intervals along the circumferential direction, and transverse ribs 2 connected between the lower parts of the plurality of vertical ribs 1, and the positions where the plurality of vertical ribs 1 are located above the transverse ribs 2 can be Elastically deformable, in this embodiment, the vertical ribs 1 are made of metal material, so they can be elastically deformed, the multiple vertical ribs 1 surround the frame of the bag cage, and the horizontal ribs 2 ensure the stability between the lower parts of the multiple vertical ribs 1 Positioning, the tops of the multiple vertical ribs 1 are all bent outwards to form a hook 3, and the upper ends of the multiple vertical ribs 1 are provided with a stretching structure 4 that can expand the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com