45-degree trimming device for angle steel

An angle steel and edge trimming technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problem of edge trimming quality, accuracy cannot be effectively guaranteed, it is not suitable for small and micro enterprises to produce, and trimming costs Improvement and other issues, to achieve the effect of easy cleaning, smooth edge cutting, and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

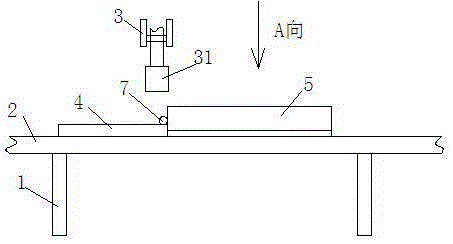

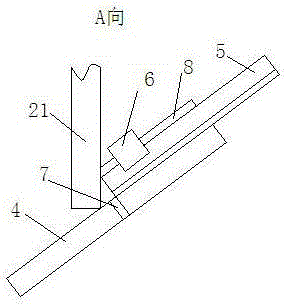

[0016] The present invention includes a frame 1, a workbench 2 is provided on the frame 1, a tool holder 3 is provided above the workbench 2, a cutter 31 is provided on the tool holder 3, and the workbench 2 is provided with A baffle 4 that forms an angle of 45° with the cutter 31. The baffle 4 forms a diagonal position of the angle steel 5 from the side. The workbench 2 is provided with a pressure plate 6 opposite to the baffle 4 , The pressing plate 6 forms the positioning of the angle steel 5 from the upper part.

[0017] A positioning rod 7 is provided in the middle of the baffle 4, and when the front end of the angle steel 5 contacts the positioning rod 7, the angle steel 5 is in a trimming position.

[0018] The workbench 2 is provided with a recessed waste trough 21 at the position of the tool rest 3.

[0019] The workbench 2 is provided with a long groove 8 between the baffle 4 and the pressure plate 6 for accommodating the angle steel 5, and an elastic pad is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com