Pressure-variable adsorption gas separation device

A gas separation and pressure swing adsorption technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increasing the instantaneous adsorption capacity of adsorbents and affecting the effective separation capacity of adsorbents, so as to improve the effective separation The effect of improving capacity, concentration and gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

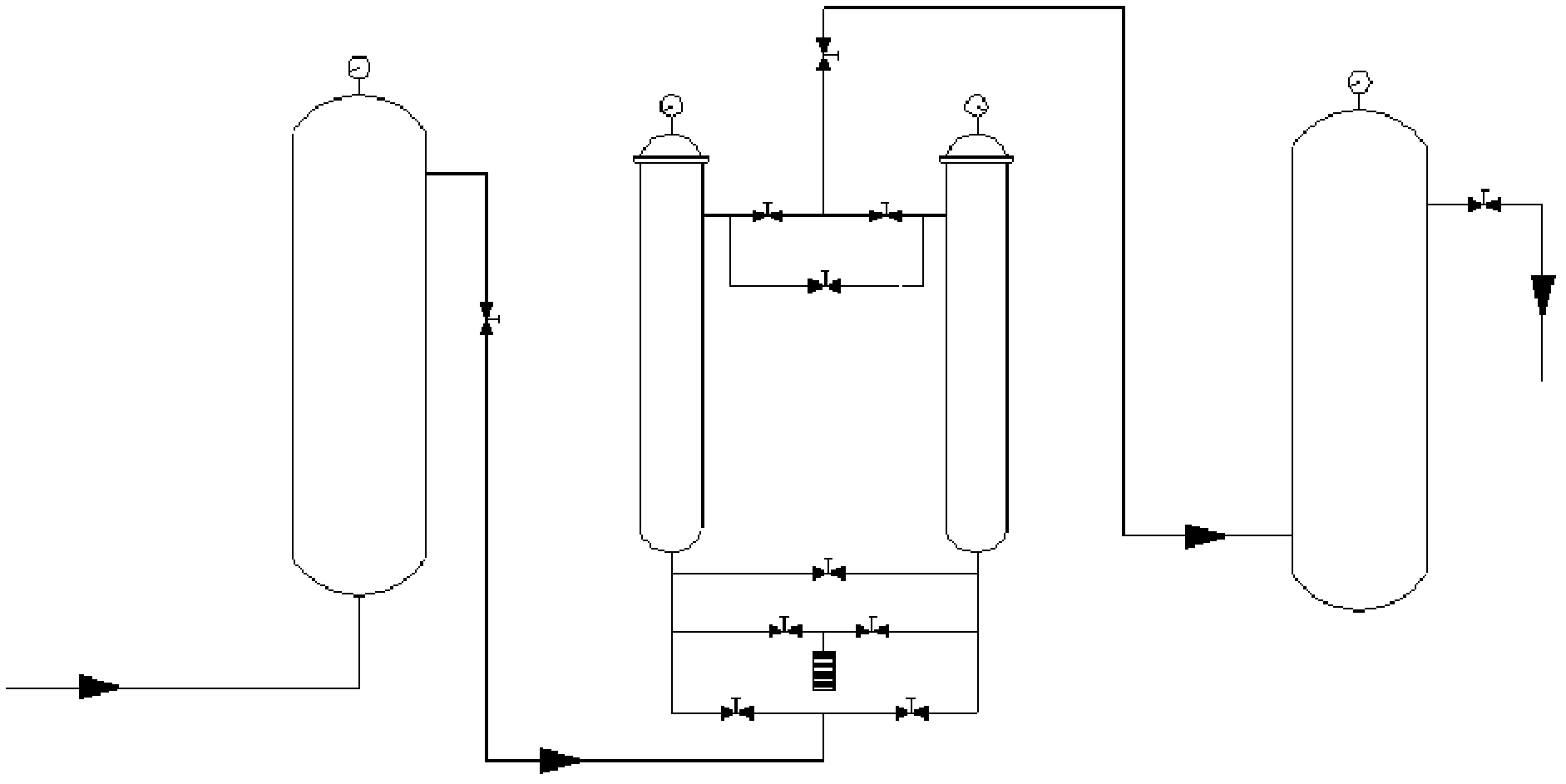

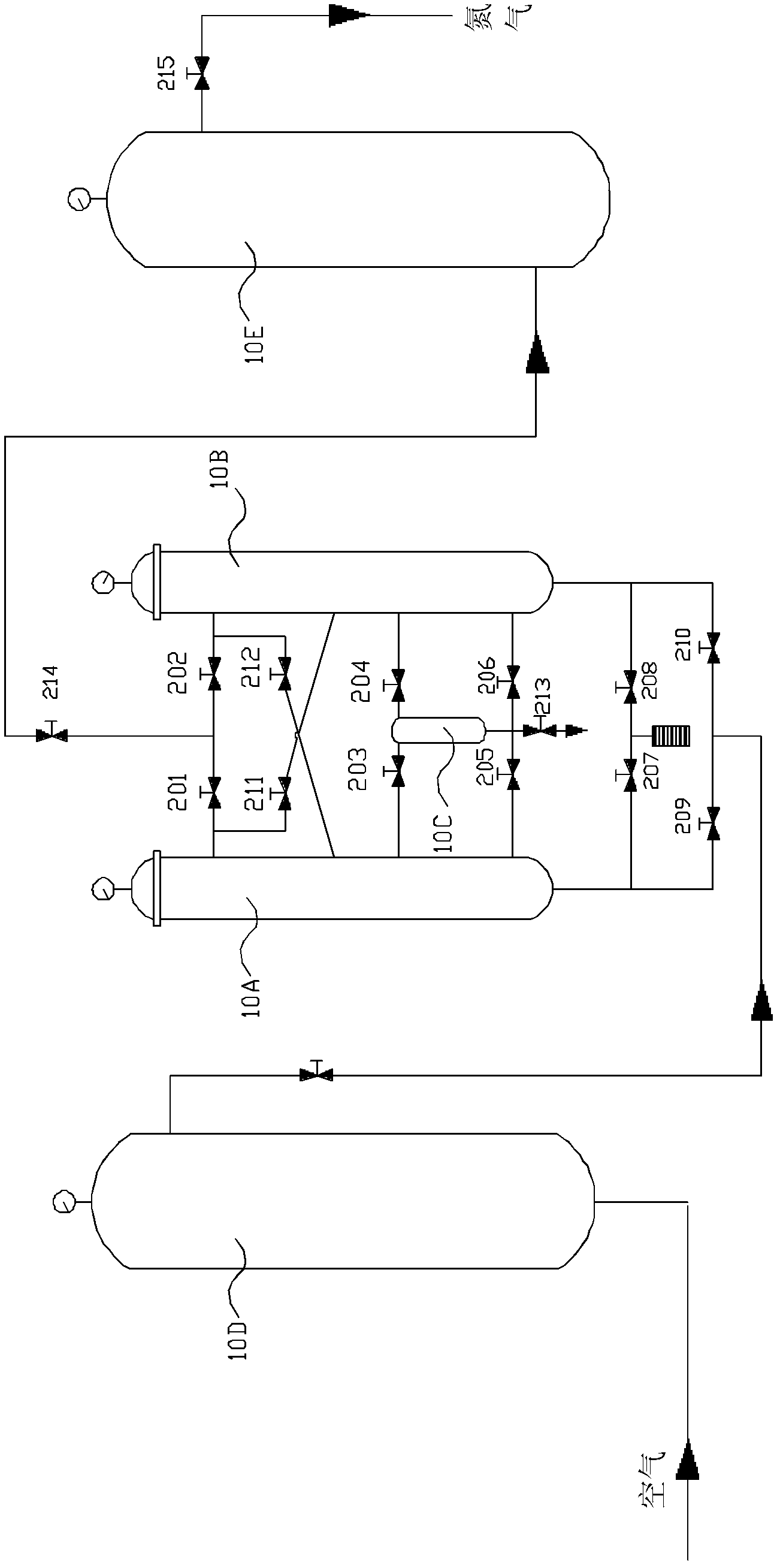

[0042] see image 3 , a pressure swing adsorption gas separation device, comprising two adsorption towers 10A and 10B, and a compressed air storage tank 10D and a nitrogen product gas storage tank 10E, an adsorption sub-tower 10C (adsorption sub-tower 10C) is arranged between the two adsorption towers Volume is 5% of adsorption tower volume), described adsorption auxiliary tower 10C is connected with adsorption tower 10A and 10B by pipeline and valve 203,204,205,206, is filled with molecular sieve adsorbent in the adsorption auxiliary tower 10C, two adsorption towers The top of the tower and the top of the tower, the bottom of the tower and the bottom of the tower are respectively connected by pipelines and valves (that is, the tops of the adsorption towers 10A and 10B are connected by pipelines and valves 201, 202, and the bottoms of the adsorption towers 10A and 10B are connected by pipelines and valves 207 , 208 are connected), the tower top of adsorption tower 10A is conne...

Embodiment 2

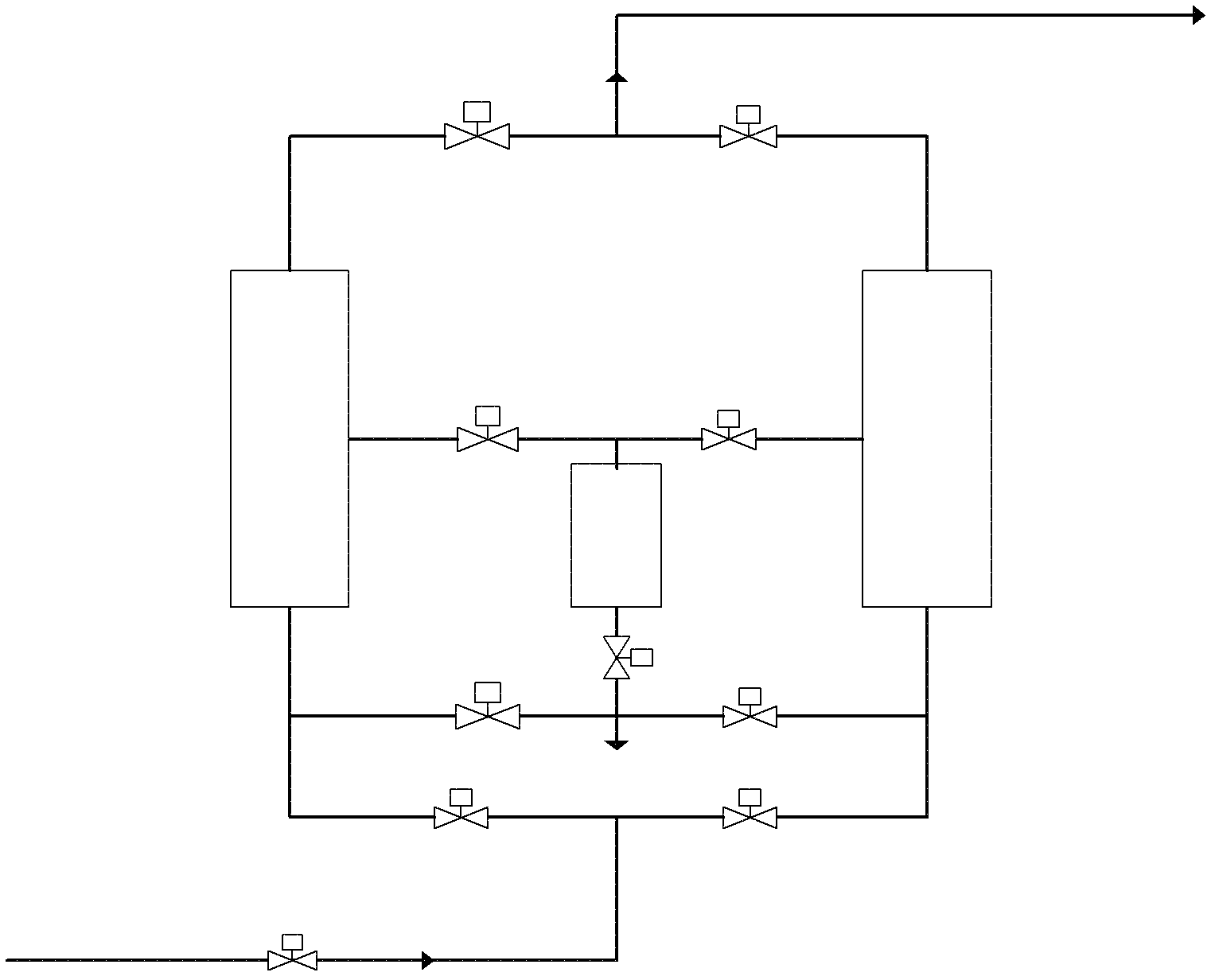

[0045] see Figure 4 , a pressure swing adsorption gas separation device, comprising two adsorption towers 10A and 10B, and a compressed air storage tank 10D and a nitrogen product gas storage tank 10E, an adsorption sub-tower 10C (adsorption sub-tower 10C) is arranged between the two adsorption towers Volume is 20% of adsorption tower volume), described adsorption sub-tower 10C is connected with adsorption tower 10A and 10B by pipeline and valve 203,204,205,206, is filled with molecular sieve adsorbent in adsorption sub-tower 10C, two adsorption towers The tower top and the bottom of the tower are respectively connected by pipeline and valve (that is, the tower top of adsorption tower 10A and 10B is connected by pipeline and valve 201,202, and the tower bottom of adsorption tower 10A and 10B is connected by pipeline and valve 207,208), adsorption The tower top of tower 10A is connected with the tower middle of adsorption tower 10B by pipeline and valve 211, and the tower top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com