Novel receiving device of color selector

A material receiving device and color sorter technology, applied in sorting and other directions, can solve impractical and uneconomical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described below in conjunction with specific embodiments.

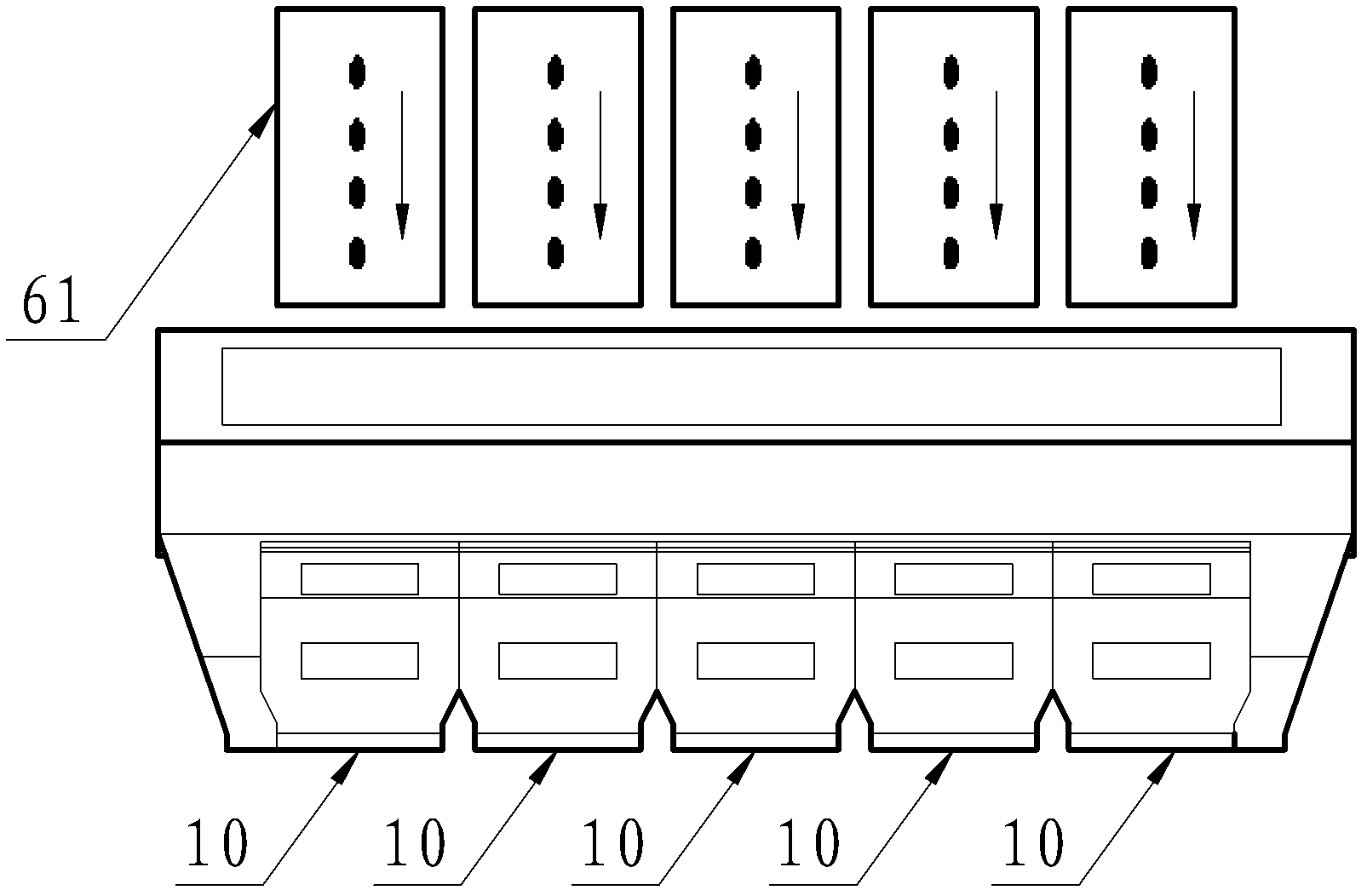

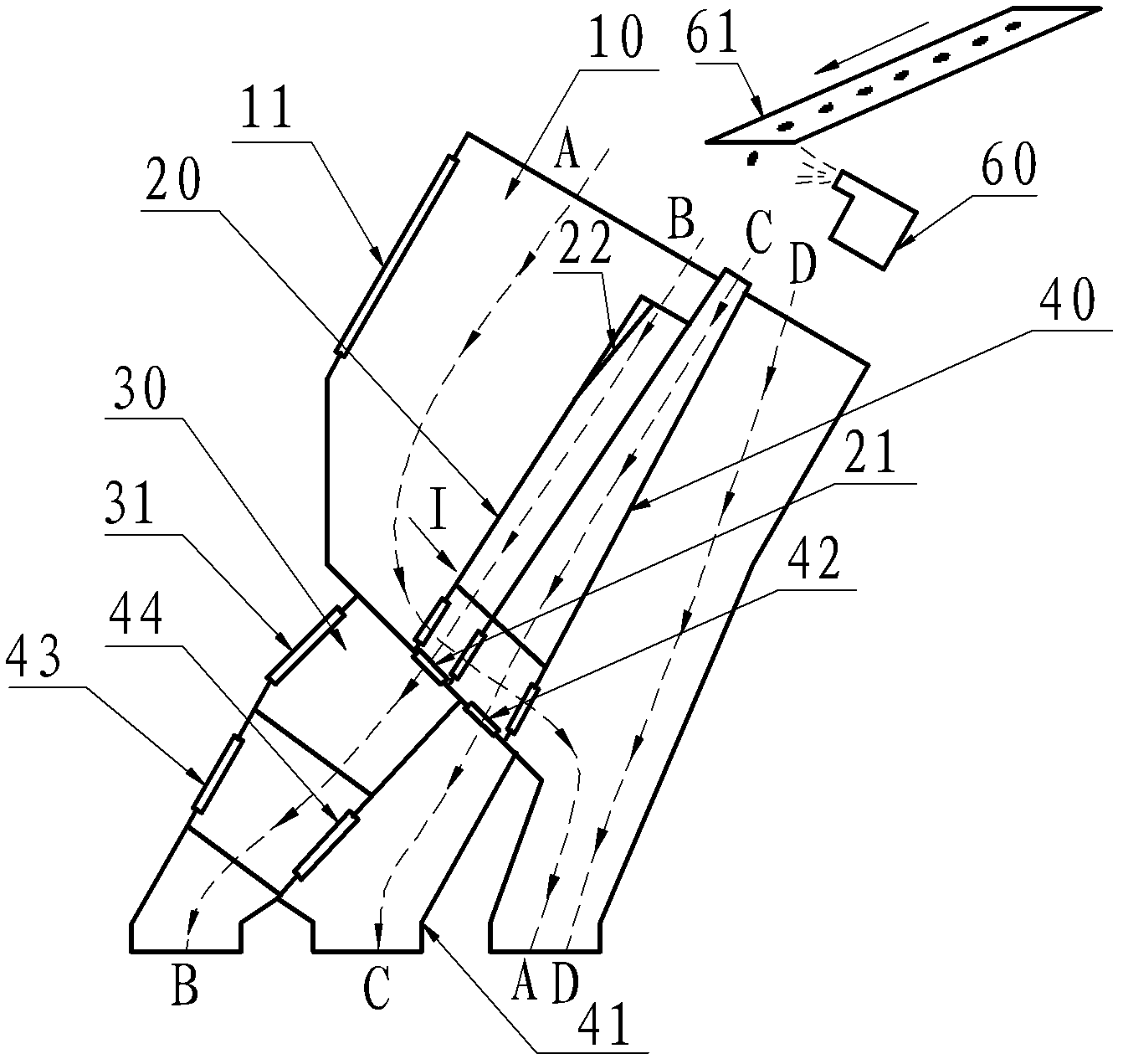

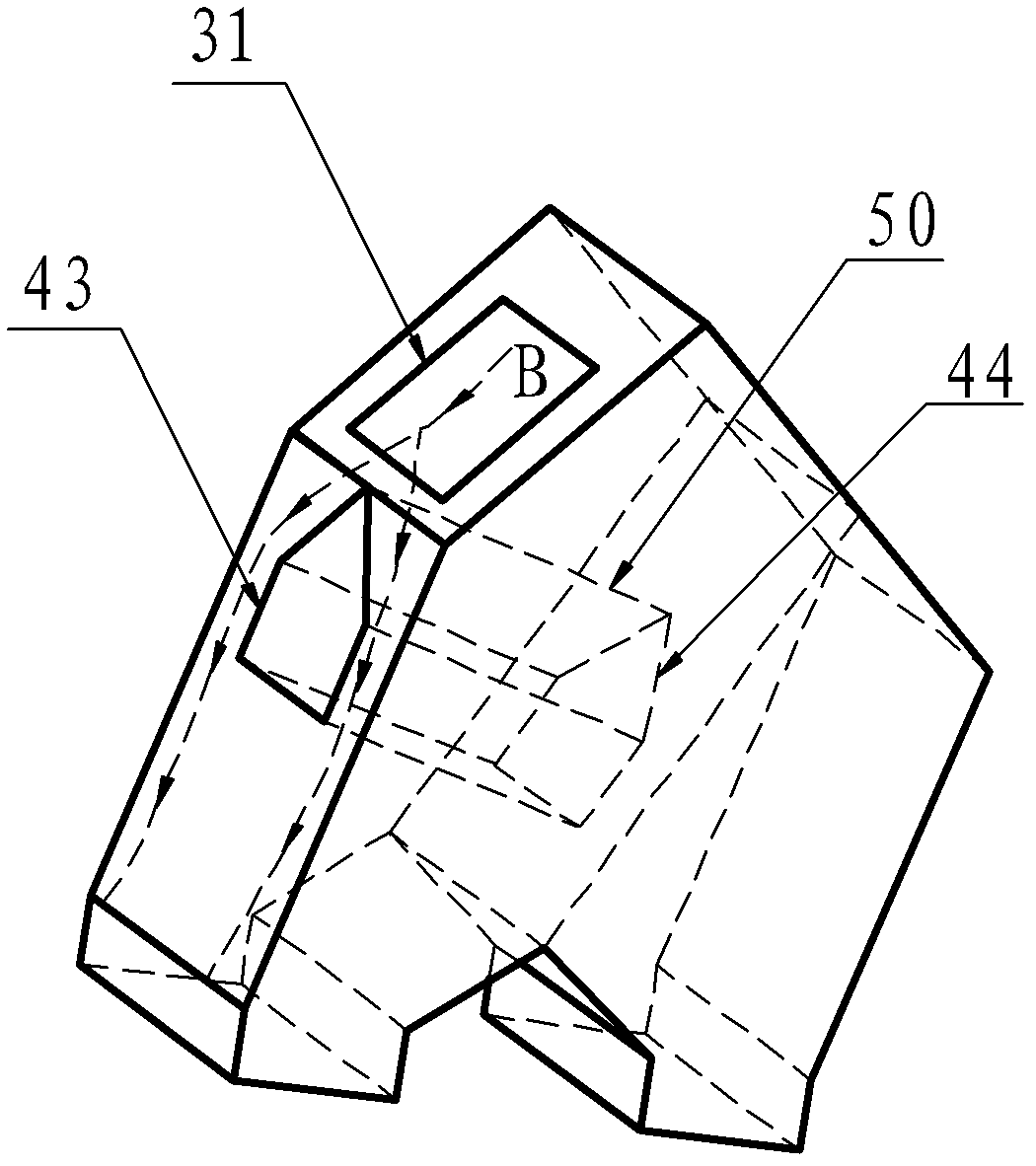

[0030] Such as figure 1 As shown, it is a structural schematic diagram of the material receiving device of the color sorter described in Embodiment 1 of the present invention, figure 2 A schematic diagram of its cross-sectional structure. The material receiving device of the color sorter of the present invention includes a bad material cavity 10, an intermediate material cavity and a good material cavity. The material enters the material receiving device of the color sorter from the feeding device 61 sequentially through vibration. Generally, each color sorter is provided with multiple groups of feeding devices 61 and receiving devices, and each group of feeding devices 61 transfers materials to their respective receiving devices, such as figure 1 Shown are five sets of receiving devices. figure 2 The left side of the color sorter is the front, that is, the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com