Steel rail cross section specification full-length fluctuation control method

A rail section and control method technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of large thickness error, small compensation value, complex shape, etc., to improve product quality and cross-section specification general length deviation Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

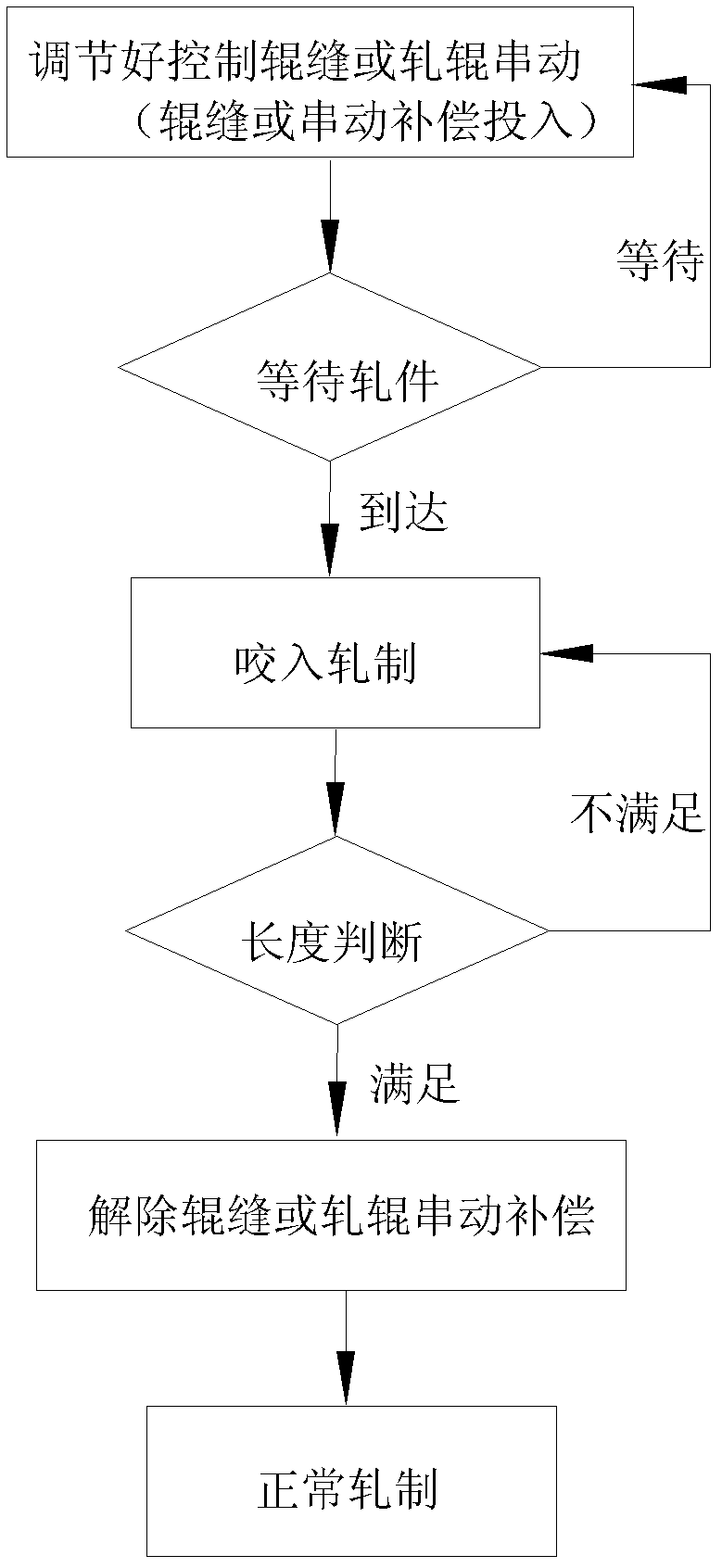

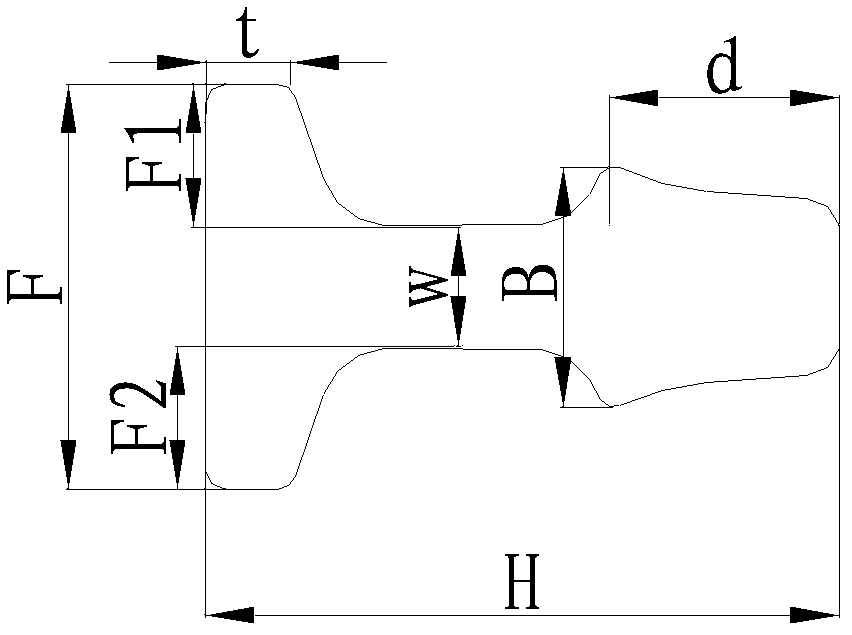

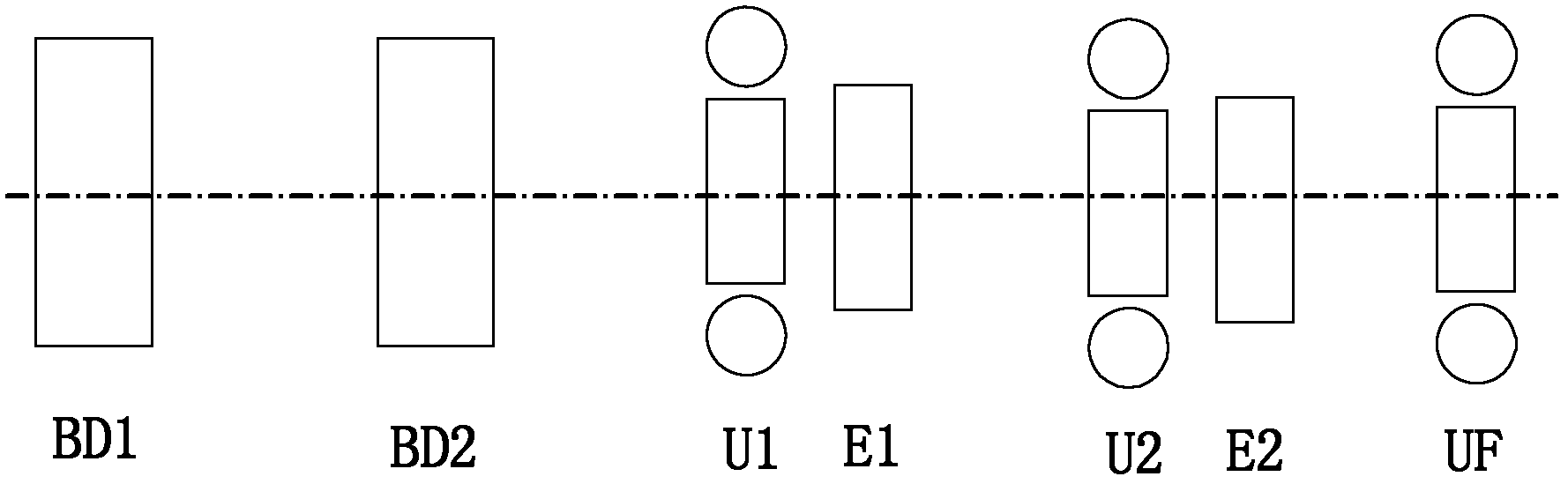

[0138] Such as image 3 , Figure 4 , Figure 5 with Figure 6 , Figure 7 As shown, taking the rolling 60kg / mU75V rail as an example, the standard bottom width F is 150mm, and the layout of the rolling mill is shown in image 3 , 60kg / mU75V rail adopts seven racks to produce rails, the blanking unit consists of two racks, which are respectively billeting machine BD1 and billeting machine BD2, the universal rolling mill has five racks, and three universal rolling mills are universal rolling mill U1, The universal rolling mill U2 and the universal rolling mill UF have two edging stands, respectively the first edging machine E1 and the second edging machine E2, according to image 3 When the rolling mills of the process layout roll the rails, the universal rolling mill UF, the second edge rolling mill E2, and the universal rolling mill U2 each roll one pass, while the first edge rolling mill E1 rolls two passes, and the universal rolling mill U1 rolls three passes. In its c...

Embodiment 2

[0151] Such as image 3 , Figure 4 , Figure 5 with Figure 8 , Figure 9 As shown, another batch of 60kg / mU75V steel rails is normally rolled and the rolling mill layout is the same as that of Embodiment 1. For the rolling mill layout process diagram, see image 3 ,according to image 3 When the rolling mills of the process layout roll the rails, the universal rolling mill UF, the second edge rolling mill E2, and the universal rolling mill U2 each roll one pass, the first edge rolling mill E1 rolls two passes, and the universal rolling mill U1 rolls three passes , but the details of the rolling process are slightly different, and the method of the present invention is used to control the rolling of another batch of 60kg / mU75V steel rails.

[0152] I. According to the normal rolling situation, analyze the detection curve of each size of the cross section of 60kg / mU75V under normal rolling situation, and obtain the fluctuation of the cross section specification length acc...

Embodiment 3

[0164] Such as image 3 , Figure 4 , Figure 5 with Figure 10 , Figure 11 As shown, taking the rolled 60kg / mU75V rail as an example, the standard rail height H is 176mm, and the layout of the rolling mill is shown in image 3 , 60kg / mU75V rail adopts seven racks to produce rails, the blanking unit consists of two racks, which are respectively billeting machine BD1 and billeting machine BD2, the universal rolling mill has five racks, and three universal rolling mills are universal rolling mill U1, The universal rolling mill U2 and the universal rolling mill UF have two edging stands, respectively the first edging machine E1 and the second edging machine E2, according to image 3 When the rolling mills of the process layout roll the rails, the universal rolling mill UF, the second edge rolling mill E2, and the universal rolling mill U2 each roll one pass, while the first edge rolling mill E1 rolls two passes, and the universal rolling mill U1 rolls three passes. In its c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com