Die for pre-deformation part of hexagon flange bolt

A flange face bolt and pre-deformation technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable parts quality, reduced material utilization rate, and the outer circle of the flange face cannot meet the requirements, etc. To achieve the effect of ensuring the screw height of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

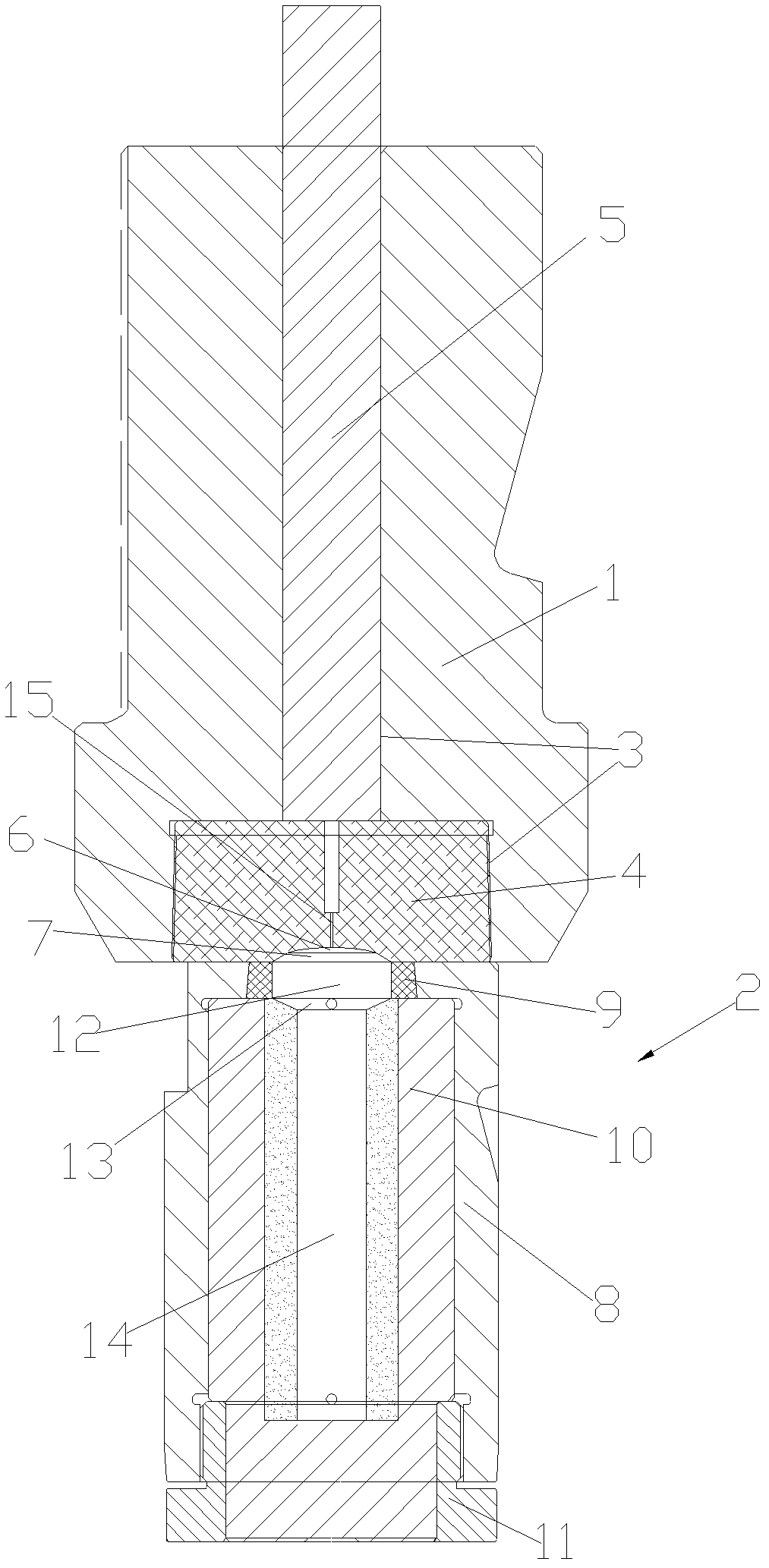

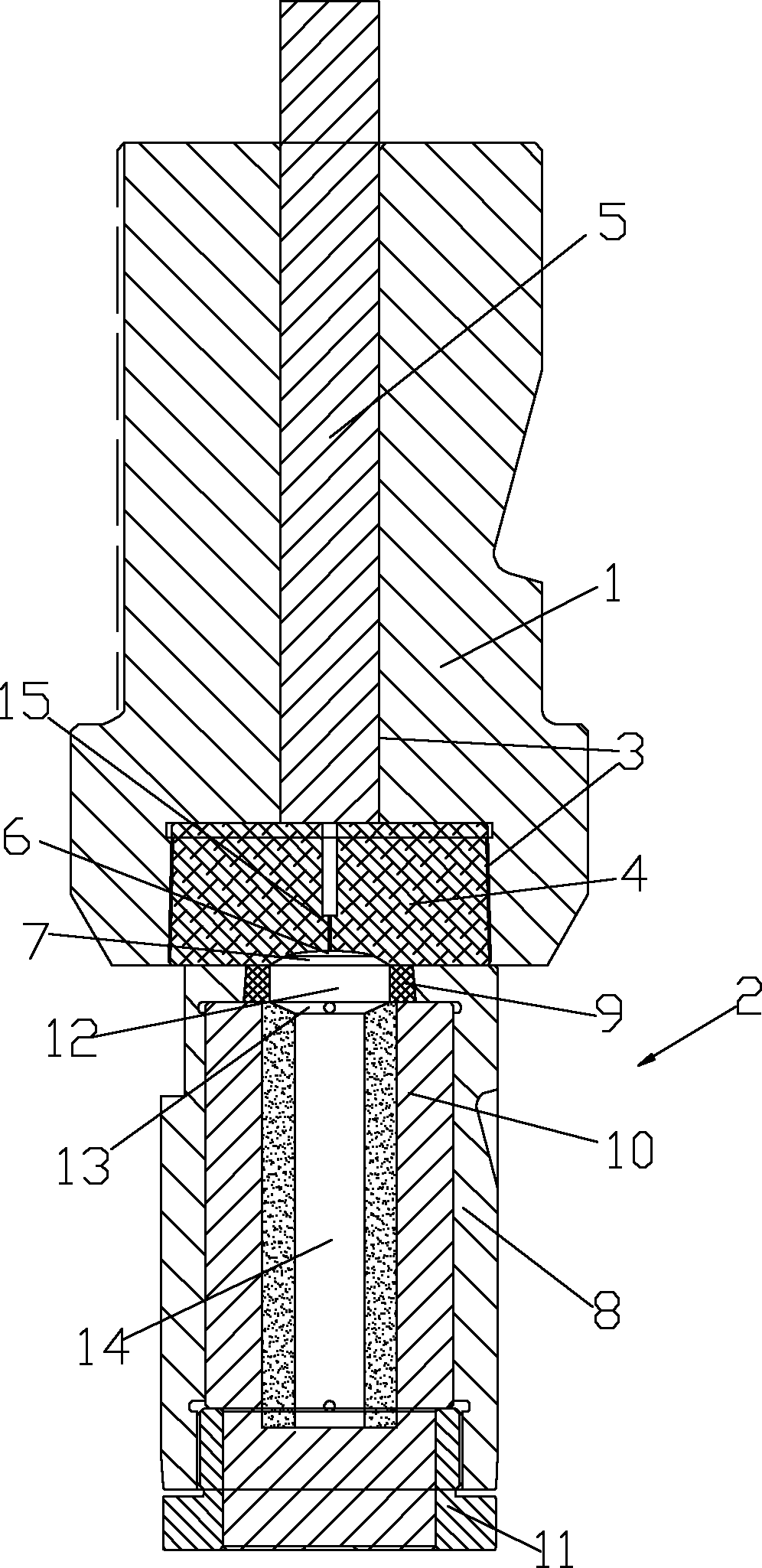

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 , 2 It is a hexagonal flange surface bolt pre-deformation part mold according to the present invention, comprising an upper mold 1, a lower mold 2 used in conjunction with the upper mold 1, a mold cavity 3 is provided in the upper mold 1, and a mold cavity 3 is provided in the mold cavity 3. Punch 4 with an interference fit with the mold cavity 3; the mold cavity 3 is also provided with a punch 5 above the punch 4; the punch 4 is provided with a spherical cavity 6 and a spherical cavity 6 connected tapered cavity 7; the lower mold 2 includes a lower mold shell 8, a mold piece 9, a lower mold core 10 and a lock sleeve 11; the mold piece 9 and the lower mold core 10 are sequentially arranged in the lower mold shell 8; The lower mold core 10 is locked in the lower mold shell 8 through the lock sleeve 11; the die piece 9 is provided with a head cylindrical cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com